Annular curved surface titanium alloy workpiece and welding method thereof

A welding method and titanium alloy technology, applied in the field of sheet metal welding, can solve the problems of high surface roughness sensitivity, difficult to achieve high roughness, and roughness less than that of the substrate, so as to achieve no stress concentration points and reduce crack sensitivity. The effect of low hardness and roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] A welding method for a titanium alloy workpiece with an annular curved surface, comprising the following steps:

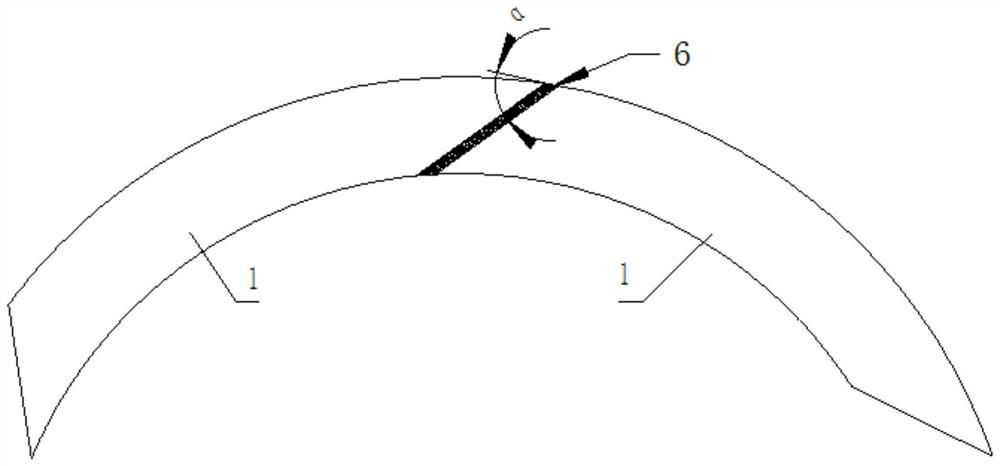

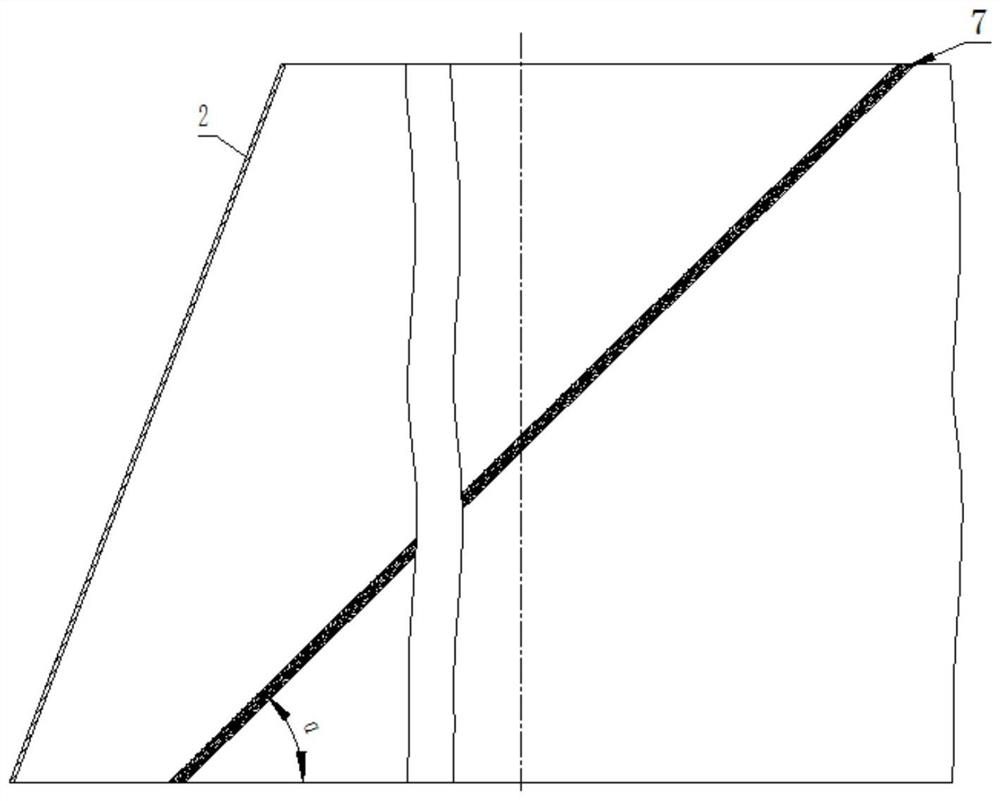

[0042] Step 1. Design the angle α of the oblique weld: According to the direction of the pulling force during forming, calculate the angle α between the weld on the cylinder and the direction of forming pulling force, that is, the angle between the welding seam and the pulling force direction can bear the pulling force during forming ;

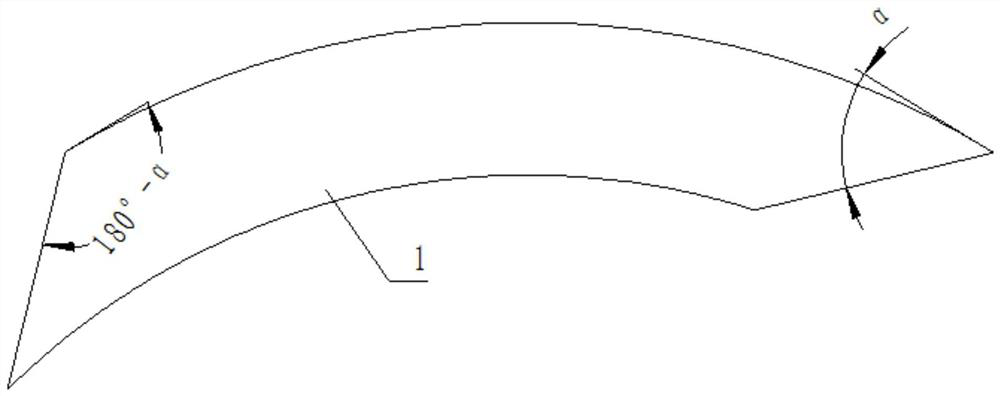

[0043] Step 2, design blanking blank 1 and blanking: According to the workpiece forming size and forming method, design the cylinder structure and calculate the cylinder size. Combined with the angle α of the oblique weld, calculate the size of the blank 1 of the flat plate blanking and blanking, and the blanking of titanium alloy parts needs to consider the material pollution problem;

[0044] Step 3, welding: make necessary pre-welding preparations for the blank to be welded, and weld it into a cylinder by automatic argon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com