Food transport vehicle with self-unloading function

A technology for transporting vehicles and food, applied in the direction of goods transporting vehicles, transporting objects, transportation and packaging, etc., can solve the problems of difficult to control flow, reduced vehicle transportation efficiency, and reduced efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode and in conjunction with the accompanying drawings.

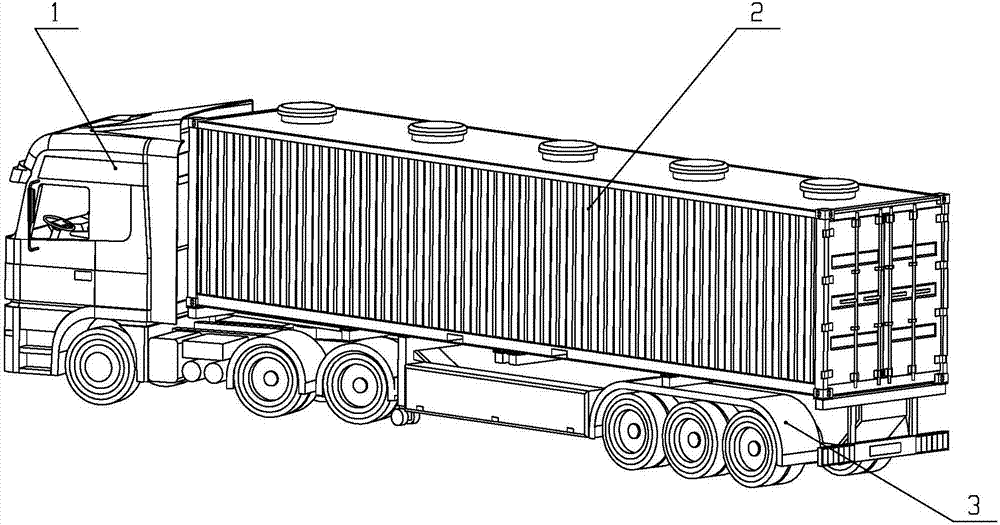

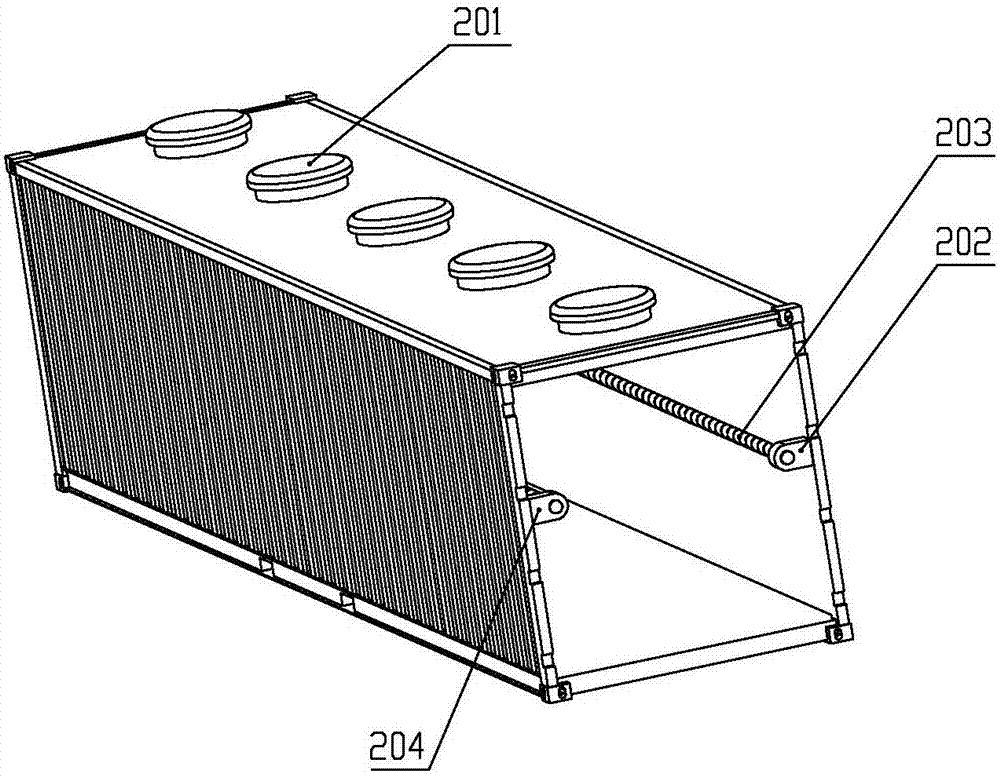

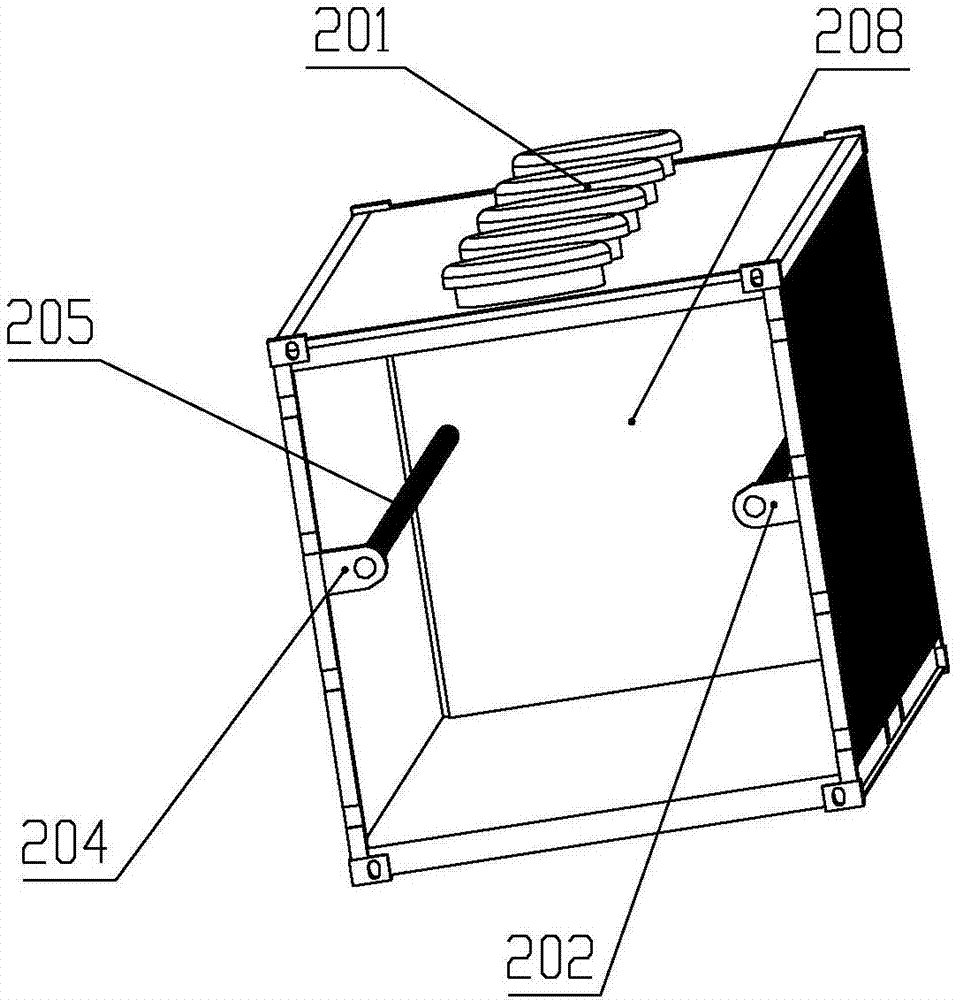

[0026] A grain transport vehicle with a self-unloading function, including a tractor 1, a cargo compartment 2, a chassis 3, and a control unit; the cargo compartment 2 includes a frame side beam, a left side panel, a right side panel, an upper compartment panel, floor, front panel, and rear door assembly; the left and right sides of the frame side beam are respectively equipped with a left side panel and a right side panel, and the frame side beam is equipped with an upper panel and a bottom panel up and down. A front panel is installed in front of the side beam of the frame, and a rear door assembly is installed behind the side beam of the frame;

[0027] N (N is greater than or equal to 2) grain loading port assemblies are installed on the upper compartment plate, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com