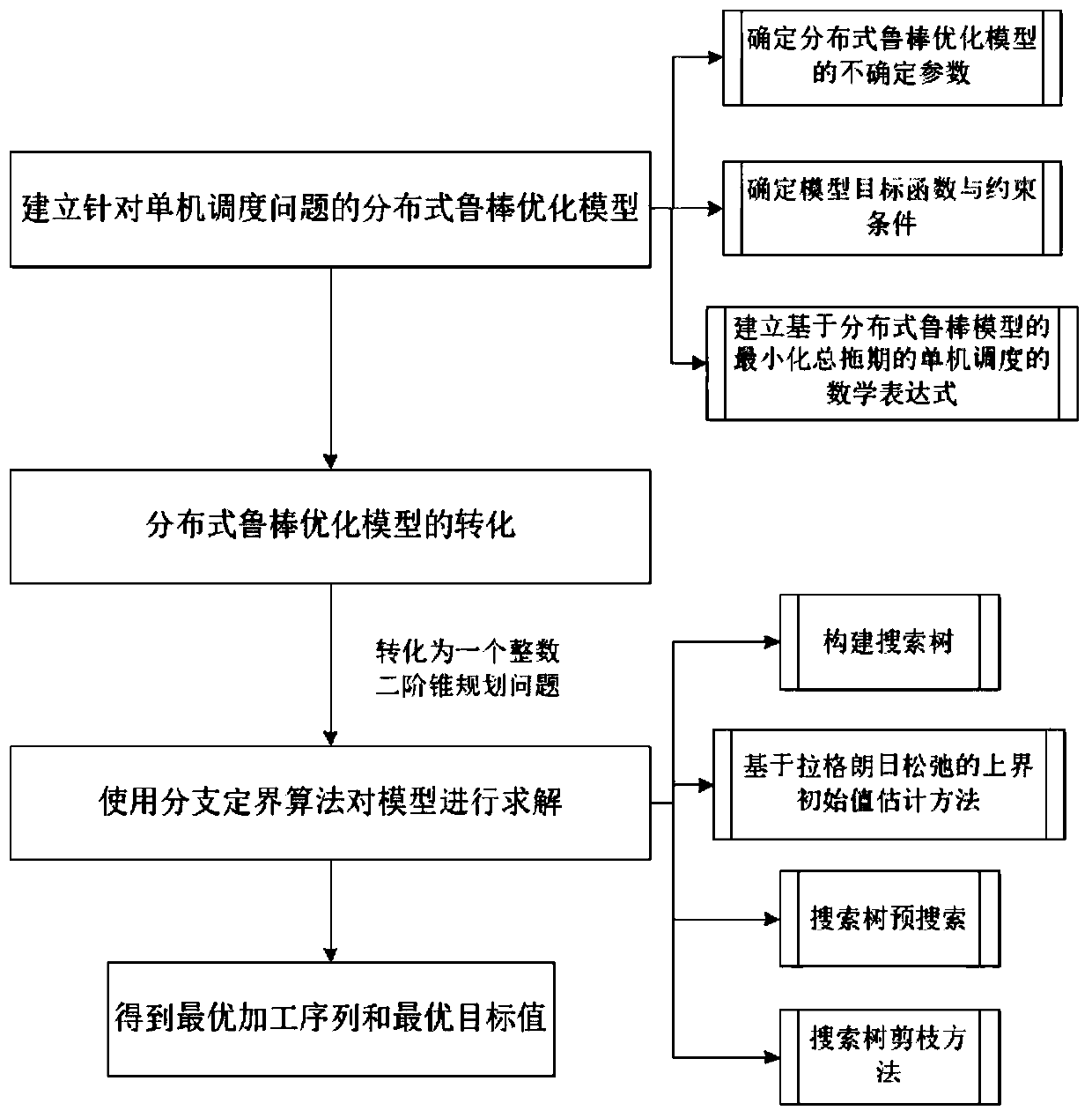

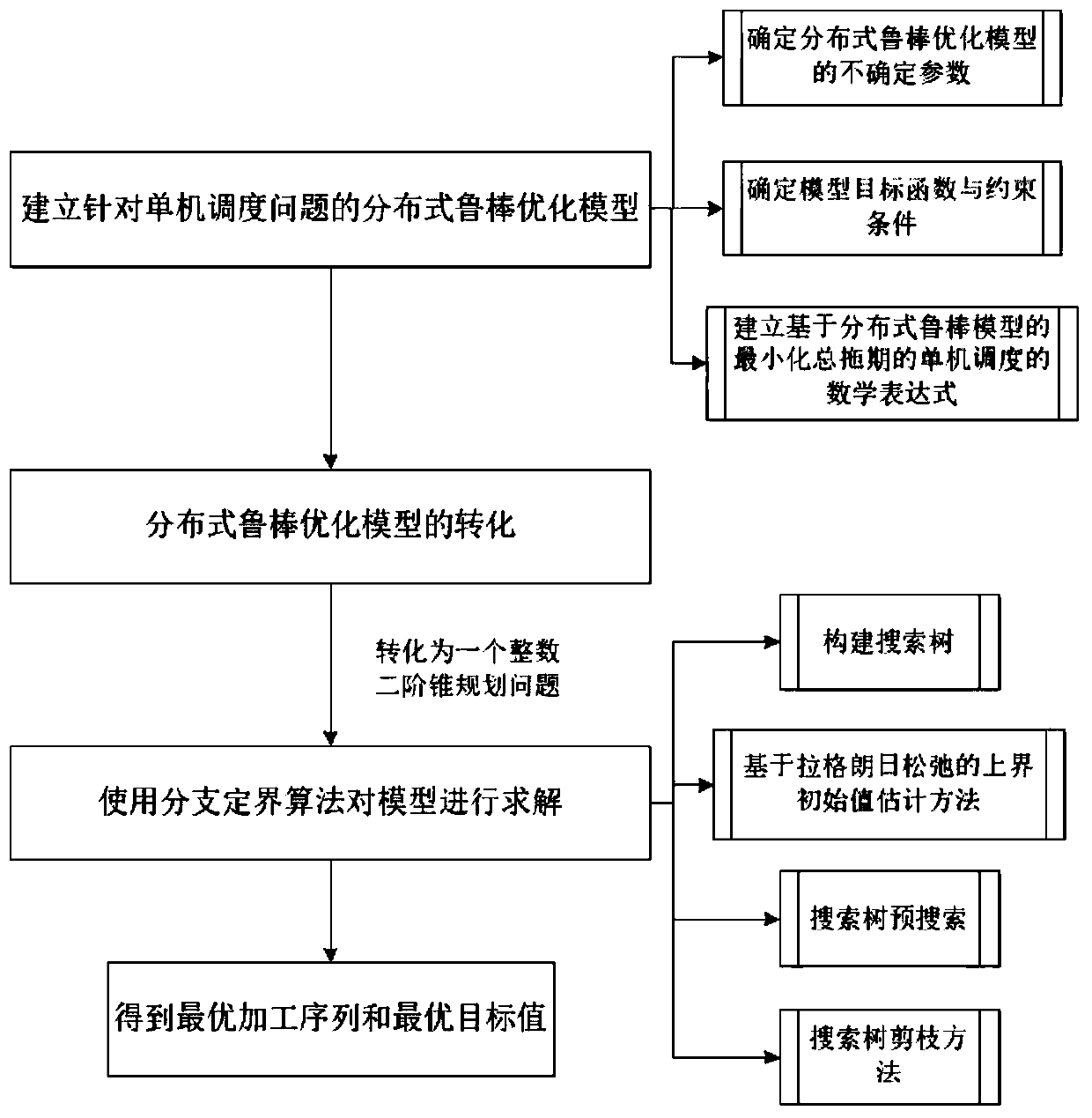

A Distributed Robust Model Based Single Machine Scheduling Method for Minimizing Total Delay

A stand-alone scheduling and distributed technology, applied in control/regulation systems, instruments, adaptive control, etc., can solve problems such as loss of performance and overconservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

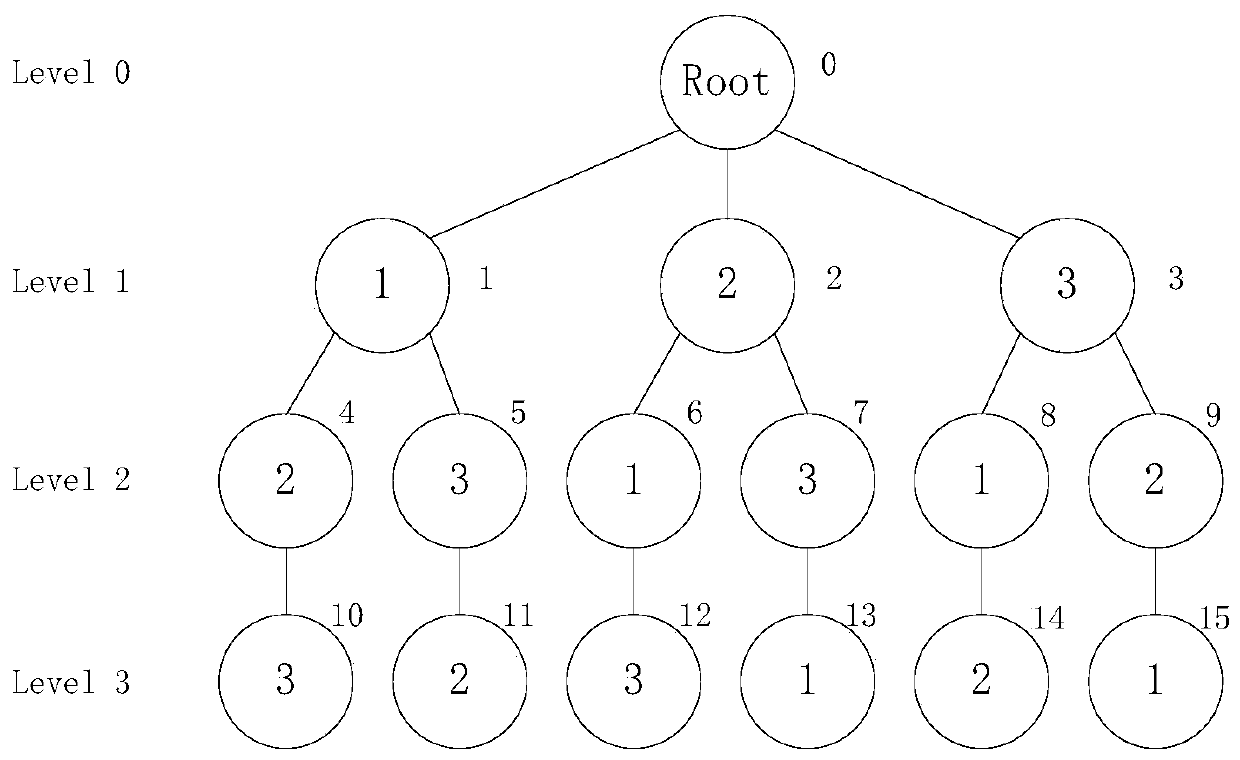

[0147] A single machine scheduling method for minimizing total delay based on a distributed robust model proposed by the present invention will be described in detail below in conjunction with embodiments.

[0148] The invention aims at the single-machine scheduling problem with uncertain parameters, and the performance index is selected as the total delay. Assuming that all workpieces are processed on one machine, each workpiece only needs to be processed once, the processing cannot be interrupted, and all workpieces are released at the beginning of processing. Each job has a processing time and a lead time. The goal of the model is to find an optimal processing sequence that minimizes the total delay.

[0149] In the distributed robust optimization model proposed by the present invention, assume that uncertain parameters are random variables independent of each other, and the distribution of each random variable is unknown, but belongs to a distribution set determined by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com