Nuclear power plant relay logic-processing cabinet testing device and method

A relay logic and test device technology, applied in electrical testing/monitoring and other directions, can solve the problems of high labor cost, long testing time, time cost, etc., and achieve the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

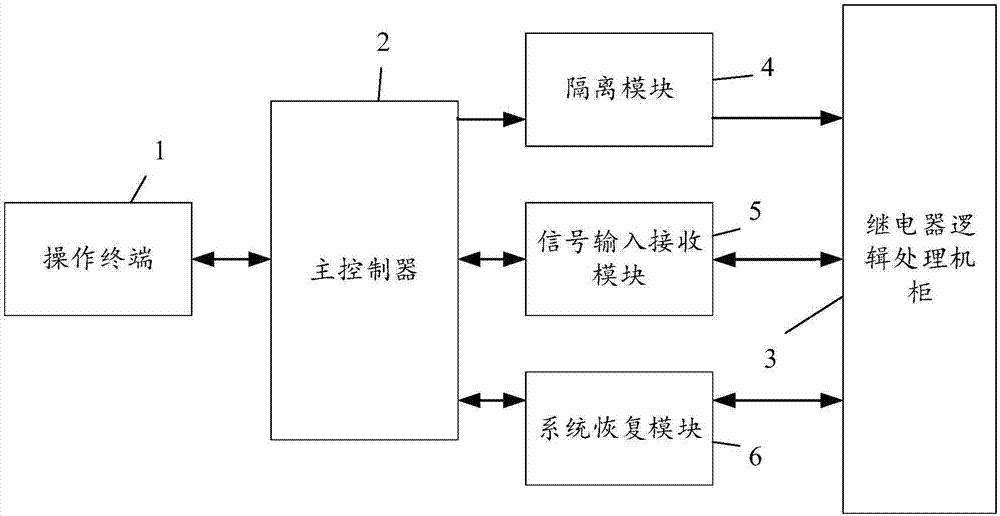

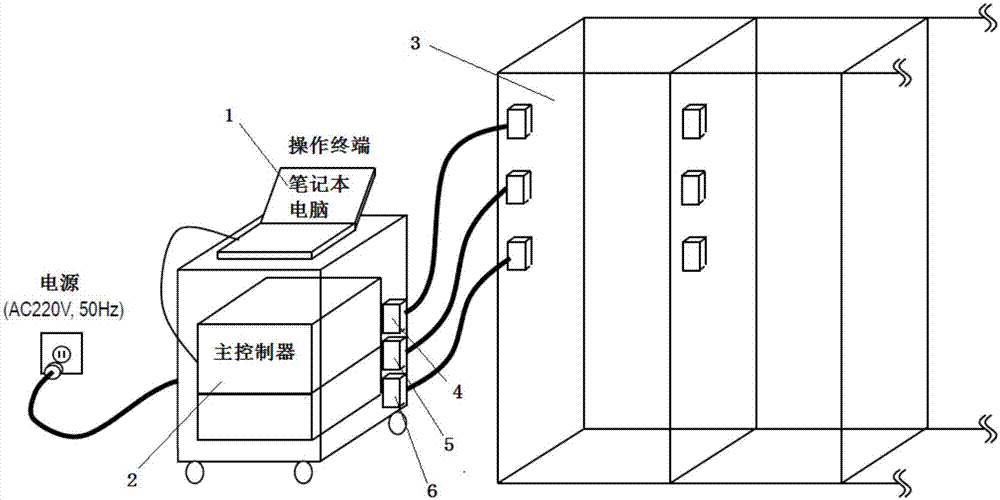

[0042] Such as figure 1 As shown, Embodiment 1 of the present invention provides a nuclear power plant relay logic processing cabinet test device, which is used to conduct regular tests on the relay logic of the relay logic processing cabinet 3, including an operation terminal 1 and a main controller 2 connected to each other. The operation terminal 1 is used to send a logic test instruction for testing the relay logic to the main controller 2, and the main controller 2 is used to receive the test instruction, and the test device also includes The isolation module 4 and the signal receiving and output module 5 between the main controller 2 and the relay logic processing cabinet 3; the main controller 2 is also used to send an isolation command to the isolation module 4 according to the logic test instruction And send a signal input command to the signal input receiving module 5; the isolation module 4 is used to isolate the signal connection between the relay logic processing ...

Embodiment 2

[0055] Such as Figure 4 As shown, Embodiment 2 of the present invention provides a test method for a nuclear power plant relay logic processing cabinet, which is characterized in that it includes the following steps:

[0056] S1. The operation terminal 1 sends a logic test instruction to the main controller 2 to test the relay logic;

[0057] S2. The main controller 2 sends an isolation command to the isolation module 4 and a signal input command to the signal input receiving module 5 according to the logic test instruction;

[0058] S3. The isolation module 4 isolates the signal connection between the relay logic processing cabinet 3 and the nuclear power system according to the isolation command;

[0059] S4. The signal receiving and output module 5 sends a relay logic test signal to the signal input end of the relay logic processing cabinet 3 according to the signal input command, and receives the relay logic output of the signal output end of the relay logic processing c...

Embodiment 3

[0063] Such as Figure 5 As shown, in the third embodiment of the present invention, the operation terminal 1 is also used to issue a system self-test instruction, a data backup instruction and a system recovery instruction to the main controller 2 .

[0064] In order to confirm that there is no connection error and that the communication is normal, steps are also included before step S1:

[0065]S01, the operation terminal 1 sends a system self-inspection instruction to the main controller 2, and the main controller 2 checks the operation terminal 1, the main controller 2, and the relay logic processing cabinet 3 when receiving the system self-inspection instruction , the isolation module 4 and the connection between the signal receiving and output module 5 to ensure that the device is connected properly.

[0066] In order not to affect the normal maintenance of the interface equipment of the relay logic processing cabinet during the test, and keep the state of the equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com