Hot swap circuit, interface circuit and electronic equipment

A hot-swappable technology for electronic equipment, which is applied in the field of hot-swappable circuits, interface circuits and electronic equipment, can solve the problems of devices and X-ray flat panel detectors in the burnt-out stage circuit that cannot work normally, so as to reduce the risk of use, Easy to achieve, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

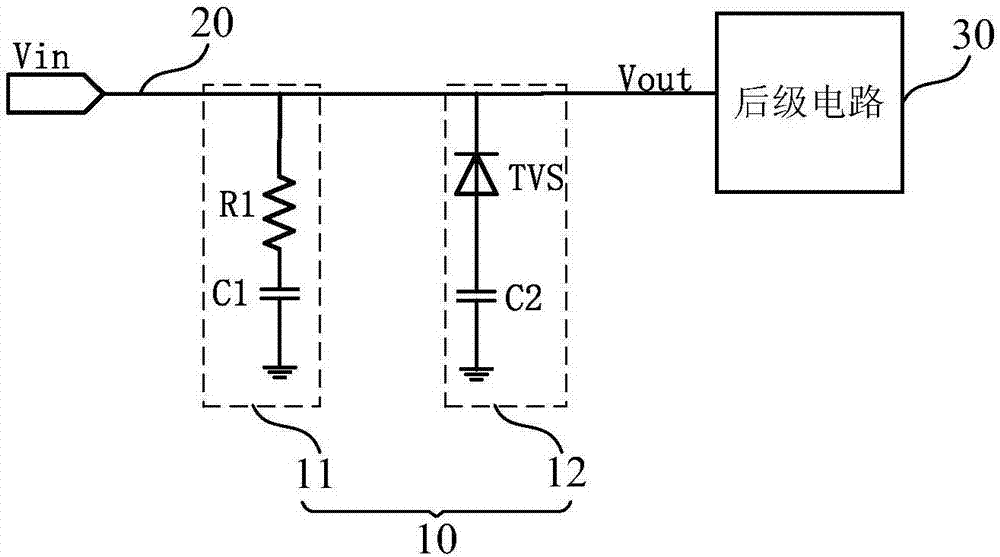

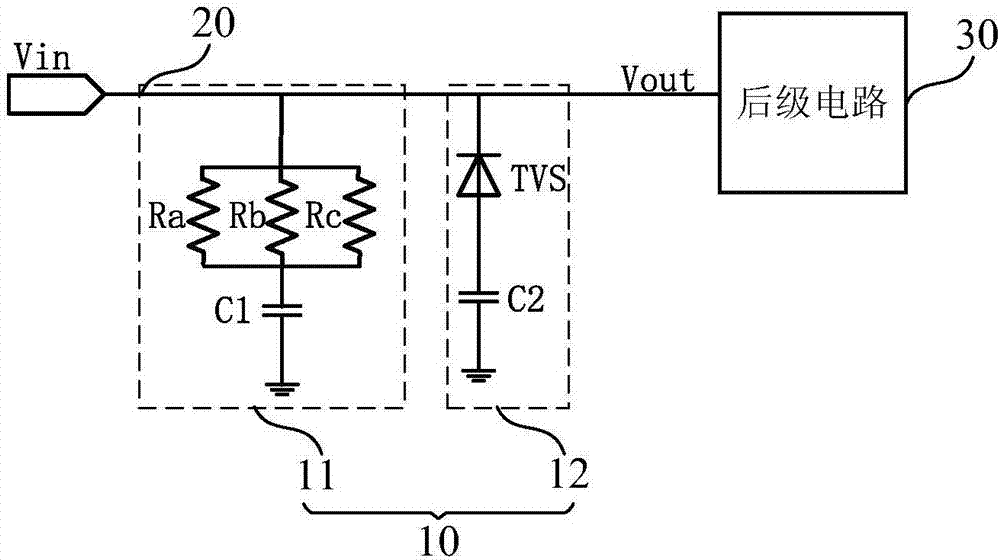

[0036] Such as figure 1 with figure 2 As shown, this embodiment provides a hot-swap circuit, and the hot-swap circuit includes:

[0037] The first-level protection unit 11 is used to consume and absorb the transient high-voltage spikes generated at the moment of hot plugging; and

[0038] The second-level protection unit 12 is connected in parallel with the first-level protection unit 11, and is used for consuming and absorbing the remaining transient high-voltage spike pulse after being consumed and absorbed by the first-level protection unit is greater than a preset voltage. Clamp the voltage across it while capturing the remaining transient high voltage spikes.

[0039] As an example, such as figure 1 As shown, the first-level protection unit 11 includes a first resistor R1, one end of the first resistor R1 is connected to the second-level protection unit 12, and the other end of the first resistor R1 is connected to the first capacitor C1 One end of the first capacito...

Embodiment 2

[0055] Such as figure 1 with figure 2 As shown, this embodiment provides an interface circuit, the interface circuit includes a power input interface line 20, and the hot swap circuit 10 connected in parallel to the power input interface line 20 as described in the first embodiment above.

Embodiment 3

[0057] Such as figure 1 with figure 2 As shown, this embodiment provides an electronic device, and the electronic device includes the interface circuit as described in Embodiment 2, and a post-stage circuit 30 connected to the interface circuit.

[0058] Preferably, in this embodiment, the electronic device includes an X-ray flat panel detector.

[0059] see below figure 1 with figure 2 The working process of the hot swap circuit is described in detail.

[0060] When the external power line plug is inserted into the power interface of the X-ray flat panel detector, the power input interface line 20 generates a transient high-voltage spike at the moment of power-on. At this time, the The first resistor R1 consumes part of the voltage energy of the transient high-voltage spike, and the first capacitor C1 absorbs part of the voltage energy of the transient high-voltage spike and releases it through the ground; when passing through the first-level protection unit When the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com