Preparation method of hydrophobic white carbon black

A technology of hydrophobic white carbon black and white carbon black, which is applied in the direction of silicon dioxide, foam dispersion/prevention, silicon oxide, etc., can solve problems such as poor anti-sedimentation, affecting the appearance and application performance of defoamers, and layered precipitation. Achieve the effects of fewer steps, improved appearance and application performance, and improved affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

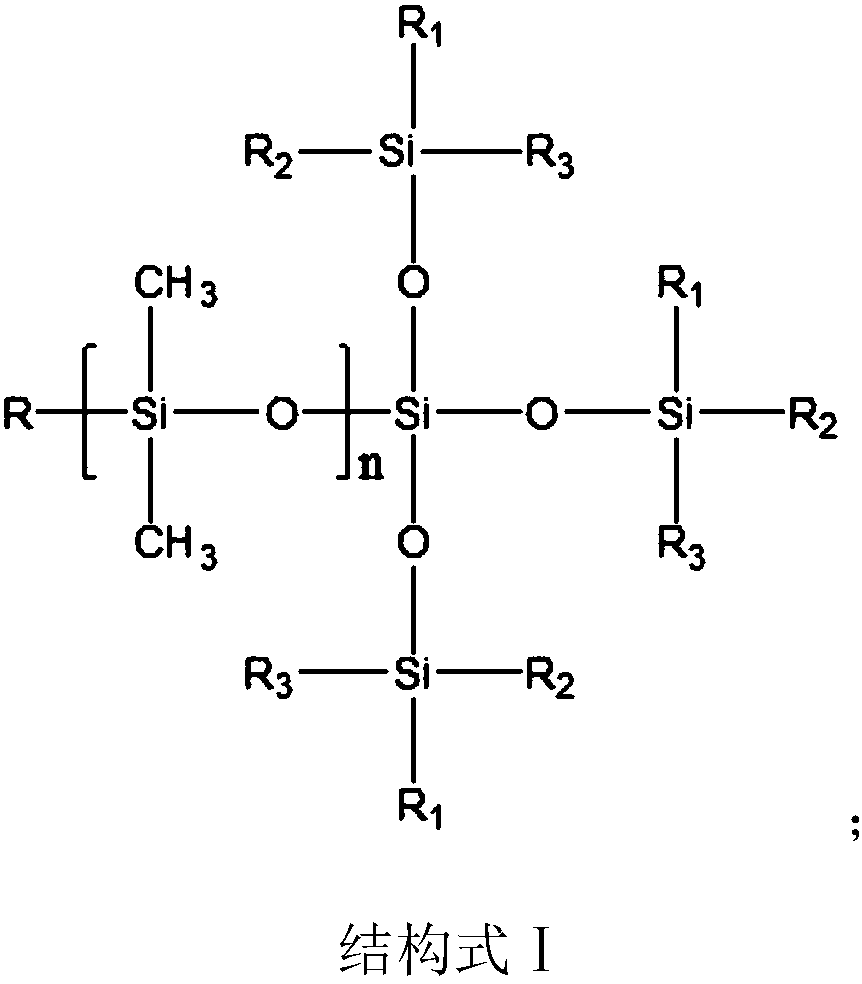

[0032] A preparation method of hydrophobic silica, which is prepared according to the following method: respectively put the treatment agent and hydrophilic silica into the reactor, mix them uniformly, add the first catalyst, raise the temperature to 60-200°C, and control the reaction The time is 2-18h, and the by-products are removed by vacuuming to obtain hydrophobic silica; the molecular structural formula of the treatment agent is shown in structural formula Ⅰ:

[0033]

[0034] Wherein, n=0-100, preferably 10-50; R is hydroxyl, carboxyl, epoxy, hydrogen or other reactive groups with silanol; R 1 , R 2 , R 3 All are alkanes, short-chain hydrocarbons, preferably methyl, ethyl or propyl.

[0035] As a further embodiment, the first catalyst is N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane, N-(β-aminoethyl)-γ-aminopropyl One or any combination of dimethylmethoxysilane and 3-aminopropyldimethylmethoxysilane.

[0036] As a further embodiment, the treatment agent is ...

Embodiment 1

[0050] A kind of preparation method of hydrophobic white carbon black, at first prepares treating agent, utilizes obtained treating agent to modify hydrophilic white carbon black, specifically as follows:

[0051] 1. Add hydroxytris(trimethylsiloxy)silane (structural formula III) into the reaction vessel;

[0052]

[0053] 2. Under the protection of nitrogen, add two-terminal hydroxy silicone oil (structural formula IV) in equimolar ratio, and stir evenly;

[0054] where n = 40;

[0055] 3. Add octanoic acid of 0.2% by weight of the total reactants as a catalyst, and heat up to 75°C;

[0056] 4. Vacuumize, reflux and condense for 9 hours, remove small molecular products, ensure that the reaction is complete, cool down and discharge to obtain a white carbon black treatment agent; the reaction process is shown in Reaction Formula II:

[0057]

[0058] Among them, R 1 , R 2 , R 3 Both are methyl, n=40;

[0059] 5. Mix the treatment agent obtained above with hydrophili...

Embodiment 2

[0061] A kind of preparation method of hydrophobic white carbon black, at first prepares treating agent, utilizes obtained treating agent to modify hydrophilic white carbon black, specifically as follows:

[0062] 1. Add hydroxytris(trimethylsiloxy)silane (structural formula III) into the reaction vessel;

[0063]

[0064] 2. Under nitrogen protection, add double-ended hydrogen-containing silicone oil (structural formula V) in equimolar ratio, and stir evenly;

[0065] where n = 60;

[0066] 3. Add 0.01% chloroplatinic acid by weight of the total reactants as a catalyst, and heat up to 55°C;

[0067] 4. Vacuumize, reflux and condense for 9 hours, remove small molecular products, ensure that the reaction is complete, cool down and discharge to obtain a white carbon black treatment agent; the reaction process is shown in Reaction Formula III:

[0068]

[0069] Among them, R 1 , R 2 , R 3 Both are methyl, n=60;

[0070] 5. Mix the treatment agent obtained above with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com