Dust remover air quantity control system and method

An air volume control system and dust collector technology, which are applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve problems such as affecting the dust removal effect, blocking filter bags, and large gaps, so as to ensure the treatment effect and reduce the The effect of blocking and improving the dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

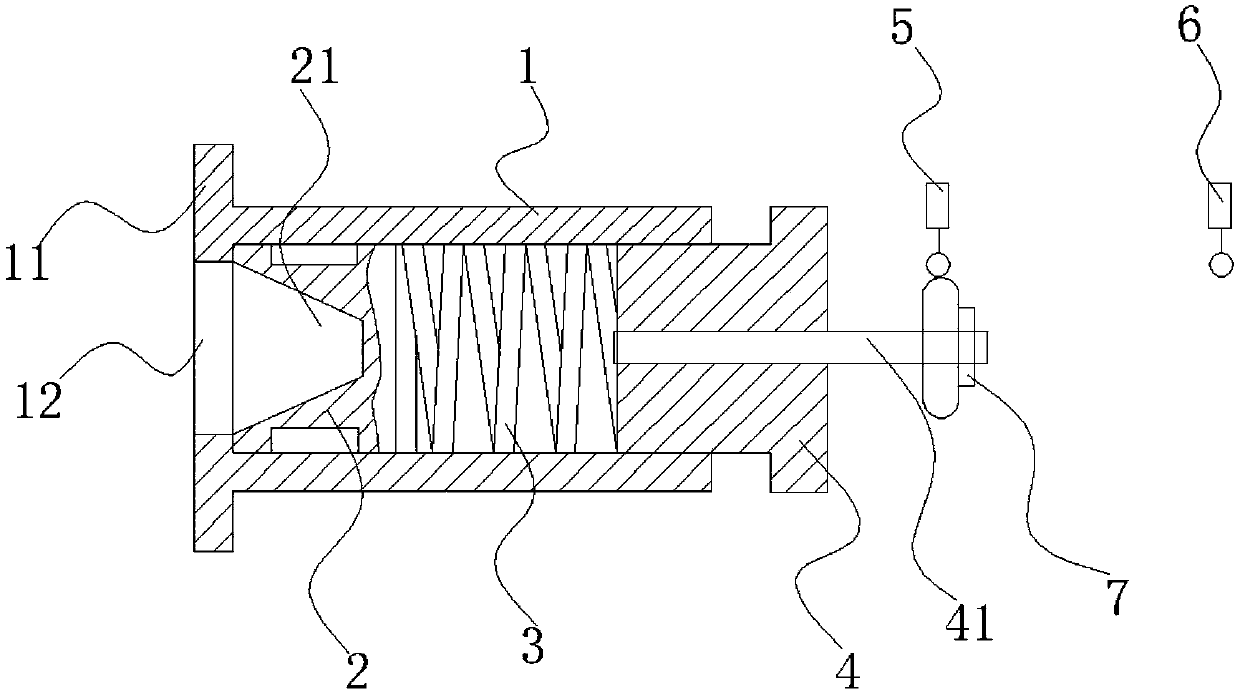

[0019] figure 1 A dust collector air volume control system according to an embodiment of the present invention is schematically shown. Such as figure 1 As shown, the dust collector air volume control system includes a cylinder 1 installed on the dust collector, a piston 2 disposed in the cylinder 1, a spring 3, a push-pull block 4, an acceleration travel switch 5 and a recoil travel switch 6.

[0020] Cylinder body 1 is circular tube shape. The end of the cylinder body 1 is provided with a mounting flange 11, and the mounting flange 11 is integrated with the cylinder body 1. The cylinder body 1 is installed on the dust collector through the installation flange 11 . The outer wall of the piston 2 is in sealing connection with the inner wall of the cylinder body 1 . Prevent the wind entering the dust collector from leaking from the gap between the piston 2 and the cylinder body 1. One end of the piston 2 is provided with a blind hole 21 opening outward. The blind hole 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com