Reflux type compressed air water discharging apparatus and use method thereof

A technology for compressed air and drainage devices, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as blockage of traps or traps with rusted impurities, affecting the quality of compressed air dew point, and inability to automatically drain water, etc. Complete functions, avoid clogging, solve the effect of easy clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

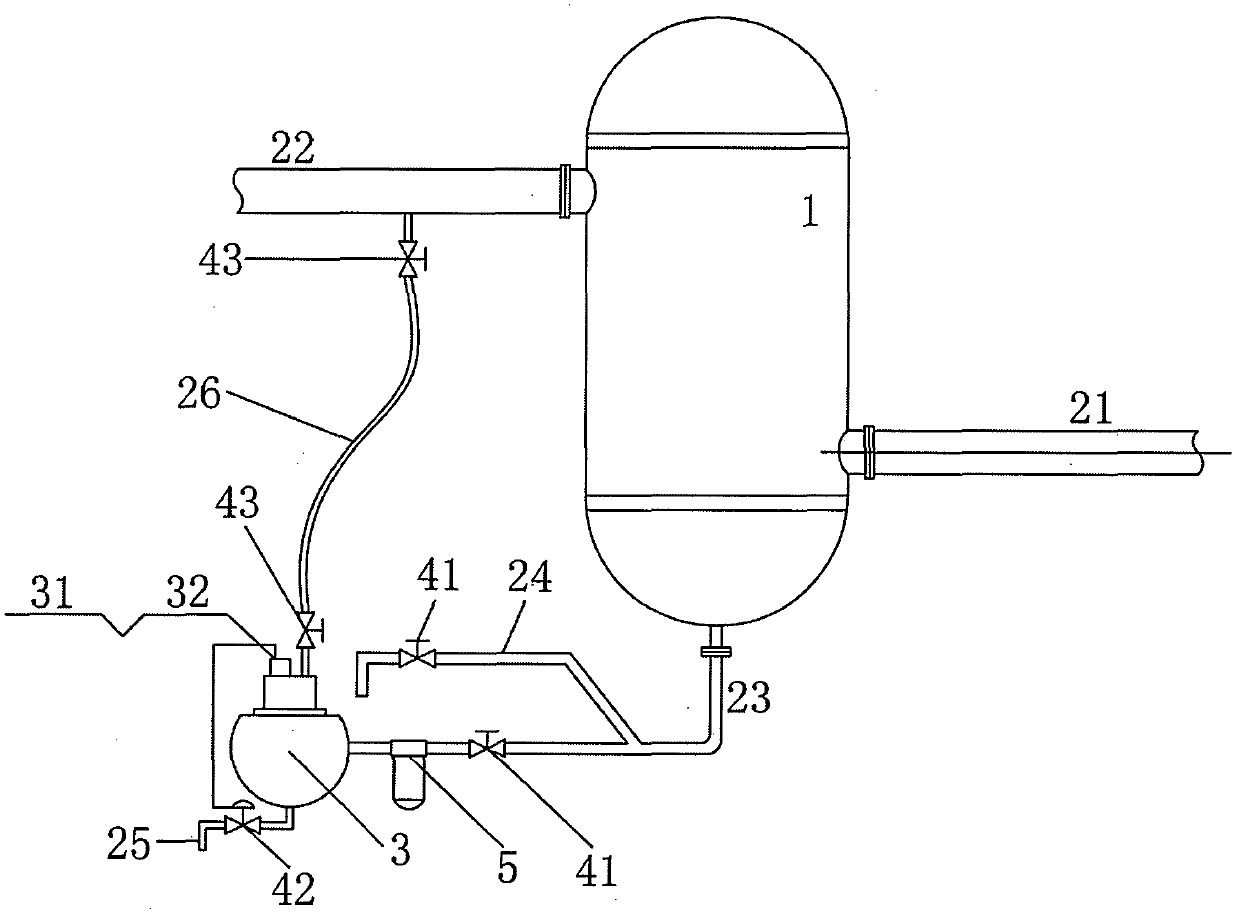

[0019] A return type compressed air drainage device, comprising a gas-water separator 1 and an automatic water trap 3, such as figure 1 As shown, the specific structure is:

[0020] The gas-water separator 1 is a carbon steel vertical storage tank with deflectors and stainless steel filter screens inside. The steam inlet and the exhaust port of the device 1 are respectively connected to the steam inlet pipe 21 and the exhaust pipe 22 through flanges;

[0021] The side, bottom and top of the automatic trap 3 are respectively provided with a water inlet, a drain and an exhaust port, and the automatic trap 3 is provided with a liquid level sensor 31 and a time controller 32;

[0022] The bottom of the gas-water separator 1 is provided with a drain port, and the two ends of the straight-through drain pipe 23 are respectively connected to the drain port of the gas-water separator 1 and the water inlet of the automatic steam trap 3, and a ball valve 41 is connected in series on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com