SBS modified asphalt stabilizer, and preparation method and application thereof

A technology of modified asphalt and stabilizer, used in building components, building insulation materials, buildings, etc., can solve the problems of low ductility, poor anti-aging ability, etc., to improve thermal storage stability, increase ductility after aging and The effect of anti-aging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a kind of preparation method of SBS modified asphalt stabilizer, comprises the following steps:

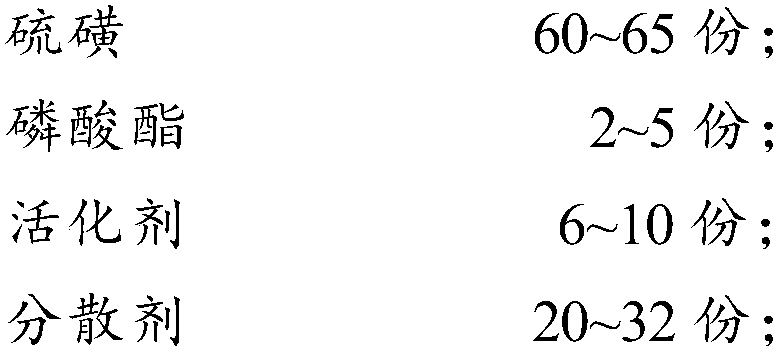

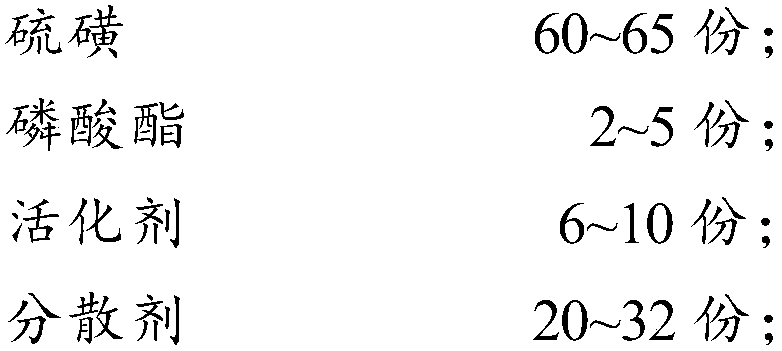

[0032] Mixing 60-65 parts by weight of sulfur, 2-5 parts by weight of phosphoric acid ester, 6-10 parts by weight of activator and 20-32 parts by weight of dispersant to obtain the SBS modified asphalt stabilizer;

[0033] The activator includes divalent metal oxide and / or divalent metal chloride; the dispersant includes one or more of rock bitumen, rubber powder and carbon black.

[0034] In the preparation method provided by the present invention, sulfur, phosphoric acid ester, activator and dispersant are mixed evenly in proportion to obtain the SBS modified asphalt stabilizer provided by the present invention. In the present invention, it is preferred to firstly mix the sulfur, phosphoric acid ester and dispersant evenly, then sieve the mixed mixture and then mix it with the activator to obtain the SBS modified asphalt stabilizer. Am...

Embodiment 1

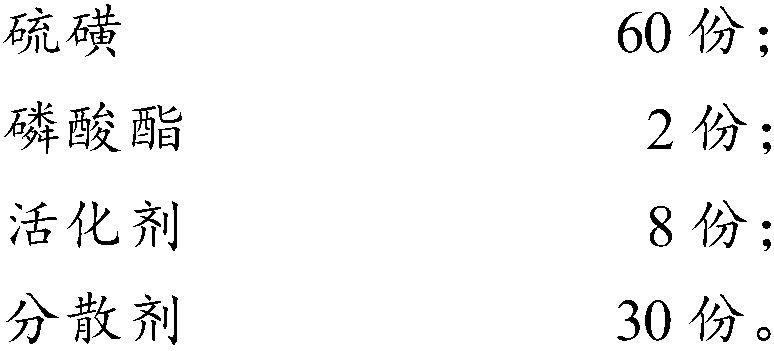

[0043] 1) prepare stabilizer:

[0044]Take by weighing 60 parts by weight of sulfur (fineness > 200 mesh), 30 parts by weight of rock pitch (fineness > 200 mesh), 8 parts by weight of zinc oxide, and 2 parts by weight of triisopropylphenyl phosphate; Rock asphalt and triisopropylphenyl phosphate are mixed uniformly by a mixer, then passed through a 200-mesh sieve, and then zinc oxide is added and mixed uniformly to obtain an SBS modified asphalt stabilizer.

[0045] 2) Preparation of SBS modified asphalt:

[0046] Weigh 500g of No. 70 A-grade road asphalt, heat it to 175-180°C, put in 23g of SBS modifier (brand YH-791), shear at high speed for 30min, then put in 1g of the above-mentioned stabilizer, and continue stirring for 3h. Obtain SBS modified asphalt. Measure each index of described SBS modified asphalt, as shown in table 1:

[0047] The indicators of the SBS modified asphalt prepared in Table 1 Example 1

[0048]

[0049]

Embodiment 2

[0051] 1) prepare stabilizer:

[0052] Take by weighing 60 parts by weight of sulfur (fineness > 200 orders), 30 parts by weight of carbon black (fineness > 200 orders), 8 parts by weight of ferrous chloride, 2 parts by weight of triisopropylphenyl phosphate; Sulfur, carbon black and triisopropylphenyl phosphate are mixed uniformly through a mixer, then passed through a 200-mesh sieve, and then ferrous chloride is added and mixed uniformly to obtain a SBS modified asphalt stabilizer.

[0053] 2) Preparation of SBS modified asphalt:

[0054] Weigh 500g of No. 70 A-grade road asphalt, heat it to 175-180°C, put in 21g of SBS modifier (brand 4303), shear at high speed for 30min, then put in 1.1g of the above-mentioned stabilizer, and continue stirring for 3h to obtain SBS modified asphalt. Measure each index of described SBS modified asphalt, as shown in table 2:

[0055] The indicators of the SBS modified asphalt prepared in the embodiment 2 of table 2

[0056]

[0057] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com