A kind of production method of phosphorus flame retardant

A technology of phosphorus-based flame retardants and production methods, applied in the direction of phosphorus organic compounds, can solve the problems of high acid value, low flash point, waste of water resources, etc., and achieve good heat storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

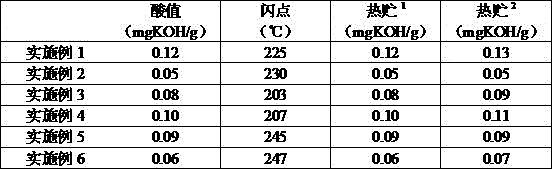

Examples

Embodiment 1

[0020] At room temperature, mix 0.25mol catalyst (aluminum triethoxide) with 1000mol POCl 3 After mixing, pump them into the kettle together.

[0021] Pump the above mixture into the closed reaction kettle, open the vent valve and fill with N 2 Displace air, close N 2 valve. Then first raise the temperature of the kettle to 50-60°C, slowly open the ethylene oxide feed valve, and start to drop 50mol ethylene oxide to induce the esterification reaction. Control the temperature of the mixed system to keep warm at 50-60°C, continue to add ethylene oxide dropwise, and keep the system temperature at 50-60°C. Slowly raise the temperature of the system to 70-80°C for aging. After 3 hours, take a sample to measure the acid value. If the acid value reaches ≤0.2mgKOH / g, close the vent valve and discharge.

Embodiment 2

[0023] At room temperature, mix 1mol catalyst (butyl titanate) with 1000mol POCl 3 After mixing, pump them into the kettle together.

[0024] Pump the above mixture into the closed reaction kettle, open the vent valve and fill with N 2 Displace air, close N 2 valve. Then first raise the temperature of the kettle to 40-50°C, slowly open the ethylene oxide feed valve, and start to drop 50mol ethylene oxide to induce the esterification reaction. Control the temperature of the mixed system to keep warm at 40-50°C, continue to add ethylene oxide dropwise, and keep the system temperature at 40-50°C. Slowly raise the temperature of the system to 60-70°C for aging. After 3 hours, take a sample to measure the acid value. If the acid value reaches ≤0.2mgKOH / g, close the vent valve and discharge.

Embodiment 3

[0026] At room temperature, mix 1.5mol of catalyst (zirconium n-propoxide) with 1000mol of POCl 3 After mixing, pump them into the kettle together.

[0027] Pump the above mixture into the closed reaction kettle, open the vent valve and fill with N 2 Displace air, close N 2 valve. Then first raise the temperature of the kettle to 40-50°C, slowly open the propylene oxide feed valve, start to drop 30mol propylene oxide to induce the esterification reaction, and control the mixing with cooling water when the reaction exothermic temperature rises. Keep the temperature of the system at 45-55°C, continue to add propylene oxide dropwise, and keep the system temperature at 45-55°C. After the addition of 3250mol of propylene oxide is completed, close the propylene oxide drop valve, and at the same time, slowly raise the temperature of the system to Aging is carried out at 60-70°C. After 3 hours, samples are taken to measure the acid value. If the acid value reaches ≤0.2mgKOH / g, clos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com