Hot-melt adhesive for hardcover book processing, and preparation method thereof

A technology of hot-melt adhesives and books, applied in the direction of adhesive types, non-polymer adhesive additives, adhesives, etc., can solve the problem of poor flatness, low adhesion between writing and book blocks, and problems between writing and books. The core is easy to detach and other problems

Inactive Publication Date: 2018-01-09

浙江越生联合出版印刷有限公司

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] This hot-melt adhesive is the same as the hot-melt adhesive for hardcover book binding in use, mainly through physical curing, which has poor flatness and poor flexibility. The adhesive is easy to tear. At the same time, after a long time, the adhesive becomes brittle. Under the action of external force, it is easy to fall off from between the writing and the book block, resulting in a low degree of adhesion between the writing and the book block. Therefore, it can be used for a long time. Finally, the writing and the book block are easy to separate, which has the disadvantage of low life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

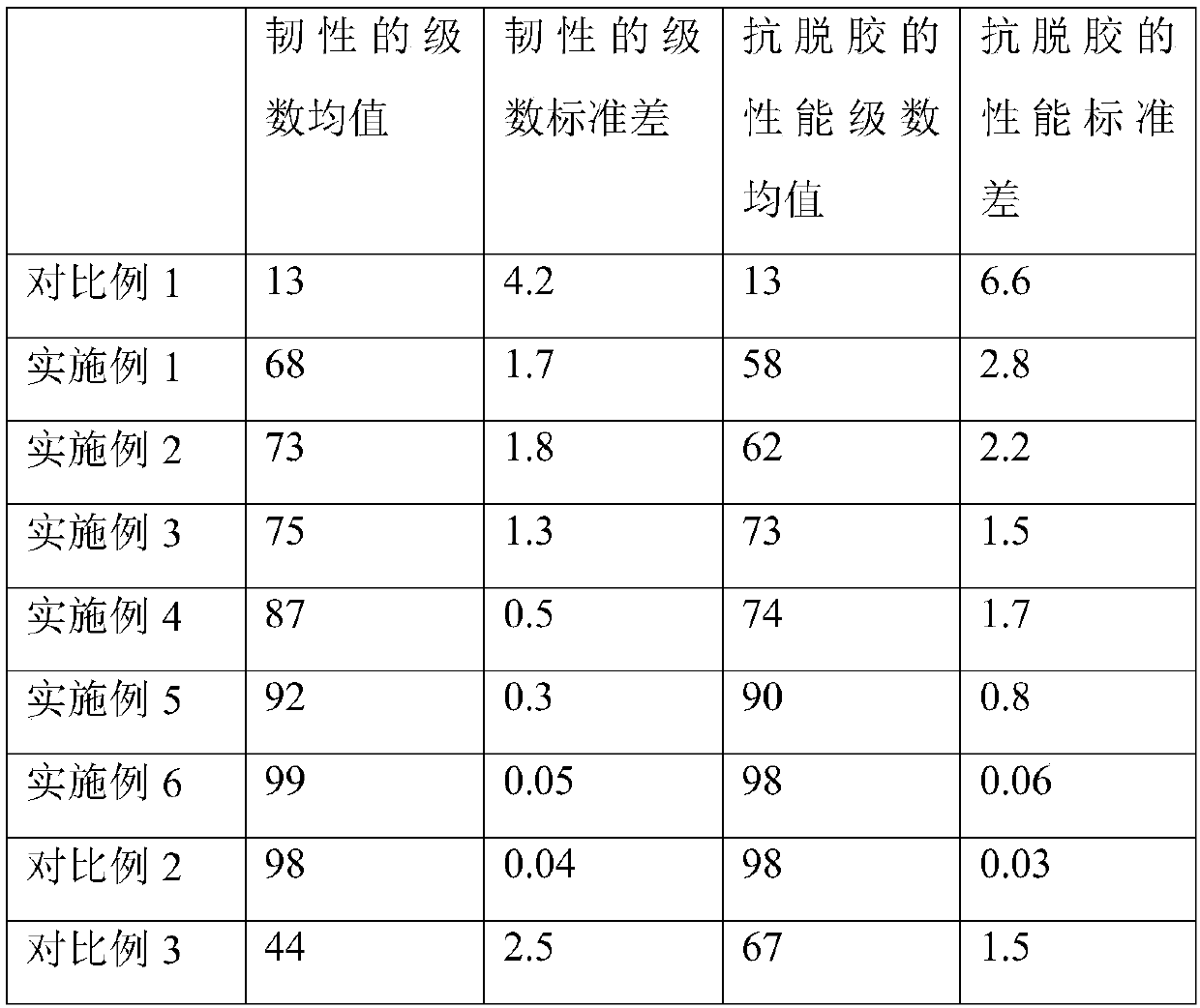

Effect test

Embodiment 1

[0026] components

Embodiment 2

[0028] components

Embodiment 3

[0030] components

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention discloses a hot-melt adhesive for hardcover book processing, and a preparation method thereof. A purpose of the present invention is to solve the problem of easy cracking in theexisting adhesive for hardcover books. The technical scheme is that the hot-melt adhesive comprises, by weight, 15-25 parts of a thermoplastic polyurethane resin, 3-10 parts of toluene diisocyanate, 30-50 parts of polyol, 2.5-8.5 parts of an anhydride group, 2-5 parts of a filler, 12-24 parts of an epoxy resin, 3-8 parts of bentonite, and 2-8 parts of petroleum wax. According to the present invention, the hot-melt adhesive obtained by using the components through the preparation method has high toughness; and when the hot-melt adhesive is adhered between the surface of the hardcover book and the core of the hardcover book, the cracking due to brittleness is not easily generated so as to prolong the service life of the hardcover book.

Description

technical field [0001] The invention relates to the technical field of hardcover book processing and manufacturing, in particular to a hot-melt adhesive for hardcover book processing and a preparation method thereof. Background technique [0002] Hardcover is a form of book binding with a protective hardback cover. Books in mainland China are generally paperback books, but paperback books are not suitable for preservation. Hardcover books are beautiful, easy-to-preserve books, and have extremely high collection value. The book block and writing of the hardcover book need to use adhesives during the processing process. Common adhesives include hot-melt adhesives. Hot-melt adhesives are adhesives with less solvents, which are melted by heat and applied to the Sticky matter, and then hardened by cooling to show adhesiveness, and thus hot melt adhesives can bond instantly and quickly, and can be used in a wide range of different fields such as paper processing, woodworking, san...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J175/08C09J179/02C09J163/00C09J11/04C09J11/06

Inventor 寿林芬

Owner 浙江越生联合出版印刷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com