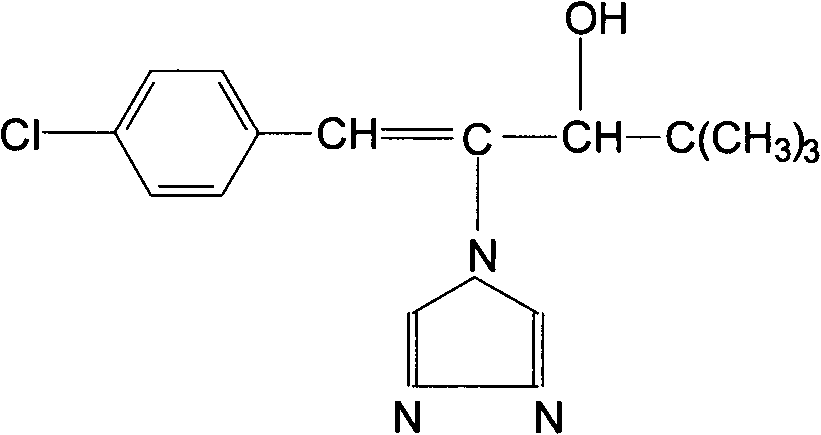

Uniconazole water dispersible granules and preparation method thereof

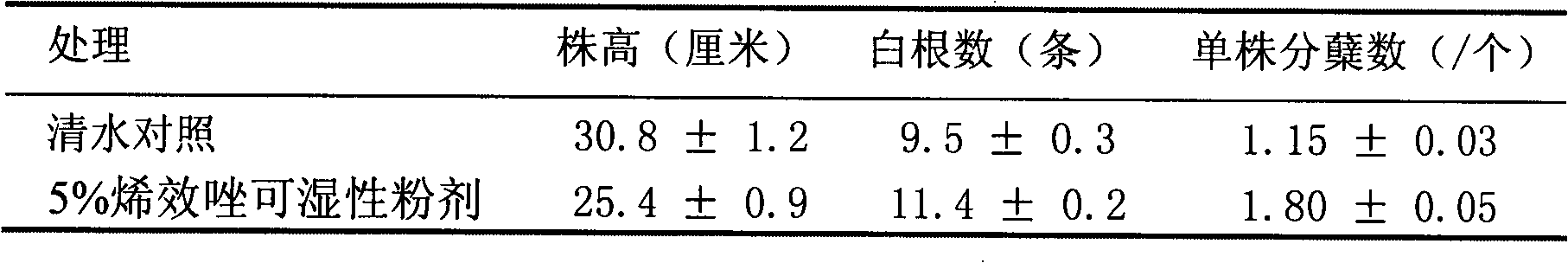

A technology of uniconazole and dispersible granules, applied in botany equipment and methods, biocides, animal repellants, etc., can solve the problems of small powder particles and easy drift, and achieve easy release and orientation, beneficial biological safety, less harmful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

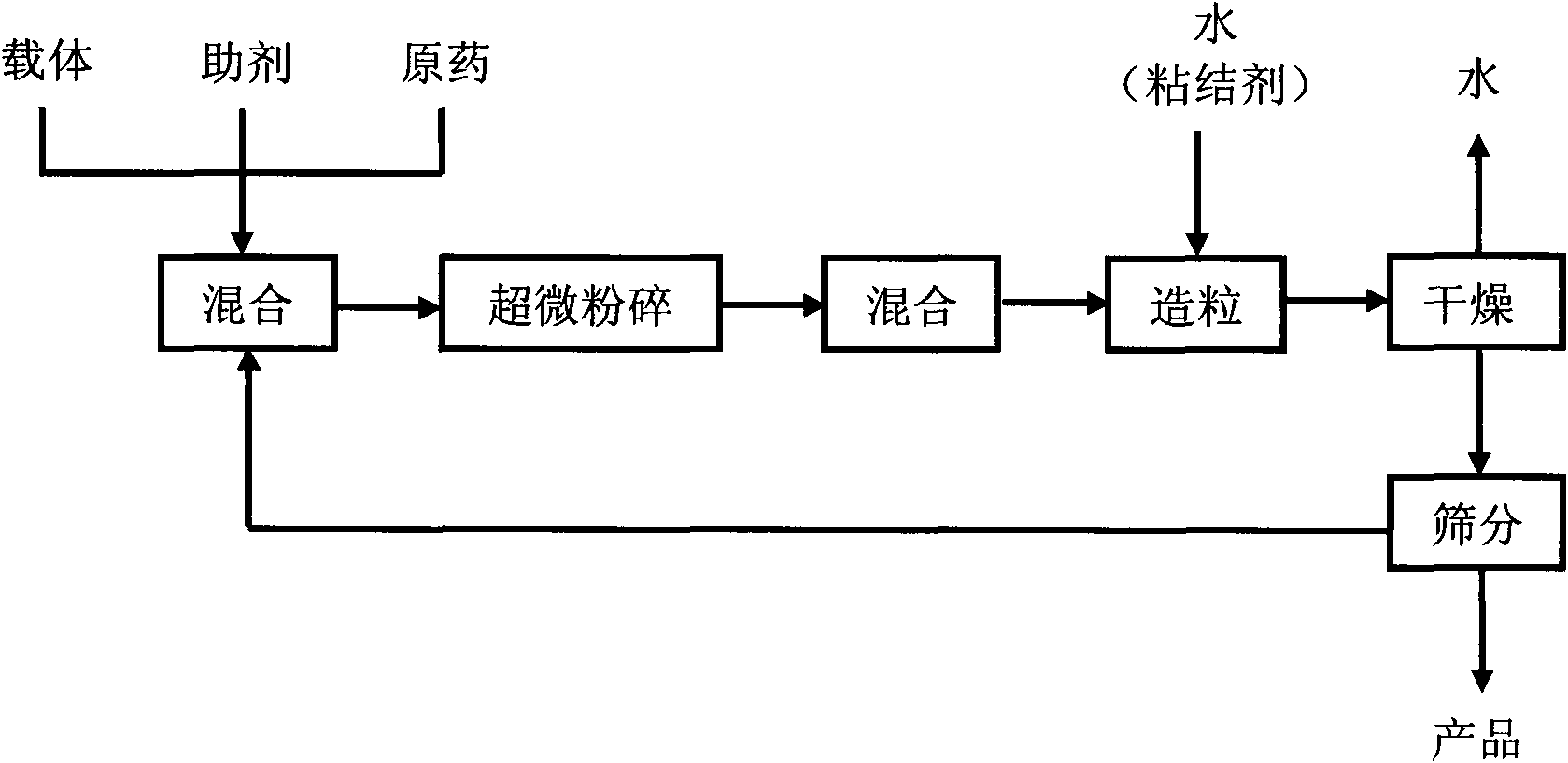

Method used

Image

Examples

Embodiment 1、01

[0026] The preparation of embodiment 1, 0.1% uniconazole water-dispersible granule

[0027] The former drug selects the 95% uniconazole former drug (hereinafter the same) produced by Jiangsu Qizhou Green Chemical Co., Ltd.

[0028] The selection and proportioning of the original drug and the auxiliary agent are: 0.105 parts by mass of the original drug of 95% uniconazole (0.1 parts by mass in pure form), the wetting agent is 2 parts by mass of dioctyl sodium sulfosuccinate, and the dispersant is lignin 5 parts by mass of calcium sulfonate, 15 parts by mass of sodium carboxymethylcellulose as a disintegrant, 2 parts by mass of polyethylene glycol as a binder, and 75.895 parts by mass of bentonite as a filler.

[0029] Calculate the amount of each component according to the above ratio, weigh, and mix evenly; the formula material is granulated after being pulverized by ultra-fine airflow; drying, screening, and testing. Product testing is carried out in accordance with the qual...

Embodiment 2、10

[0035] The preparation of embodiment 2, 10% uniconazole water-dispersible granule

[0036] The selection and proportioning of the original drug and auxiliary agents are: 10.6 parts by mass of the original drug of 95% uniconazole (10.0 parts by mass in pure form), the wetting agent is 3 parts by mass of pull-open powder BX, and the dispersant is acrylic acid copolymer salt (acrylic acid copolymer salt). and the copolymer of maleic anhydride, the average molecular weight is 15000~30000, Beijing Guangyuan Yinong Chemical Co., Ltd., trade name: GY-D06) 6 mass parts, disintegrant is ammonium sulfate 10 mass parts, binding agent is 3 parts by mass of gelatin, and 67.4 parts by mass of light calcium carbonate as the filler. The specific preparation process is the same as in Example 1.

[0037] The measurement method of each performance index of the uniconazole water-dispersible granule prepared in embodiment 2 is the same as embodiment 1. The specific measurement results are: unico...

Embodiment 3、15

[0038] Embodiment 3, the preparation of 15% uniconazole water-dispersible granule

[0039] The selection and proportioning of the original drug and the auxiliary agent are: 15.8 parts by mass of the original drug of 95% uniconazole (15.0 parts by mass in pure form), the wetting agent is 4 parts by mass of sodium lauryl sulfate, and the dispersant is lignosulfonic acid 7 parts by mass of sodium, 10 parts by mass of sodium carboxymethyl starch as a disintegrant, 5 parts by mass of polyethylene glycol as a binder, and 58.2 parts by mass of diatomaceous earth as a filler. The specific preparation process is the same as in Example 1.

[0040] The measurement method of each performance index of the uniconazole water-dispersible granule prepared in embodiment 3 is the same as embodiment 1. The specific measurement results are: uniconazole content 15.1%, moisture 1.5%, wettability qualified (5 seconds), dispersibility (disintegration) qualified (12 times), foaming property qualified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com