Method for evaluating ultraviolet shielding properties of nano powder material

A nano-powder, external shielding technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of UV shielding properties that are not suitable for nano-powder materials, and achieve fast analysis and testing speed, good data reproducibility, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

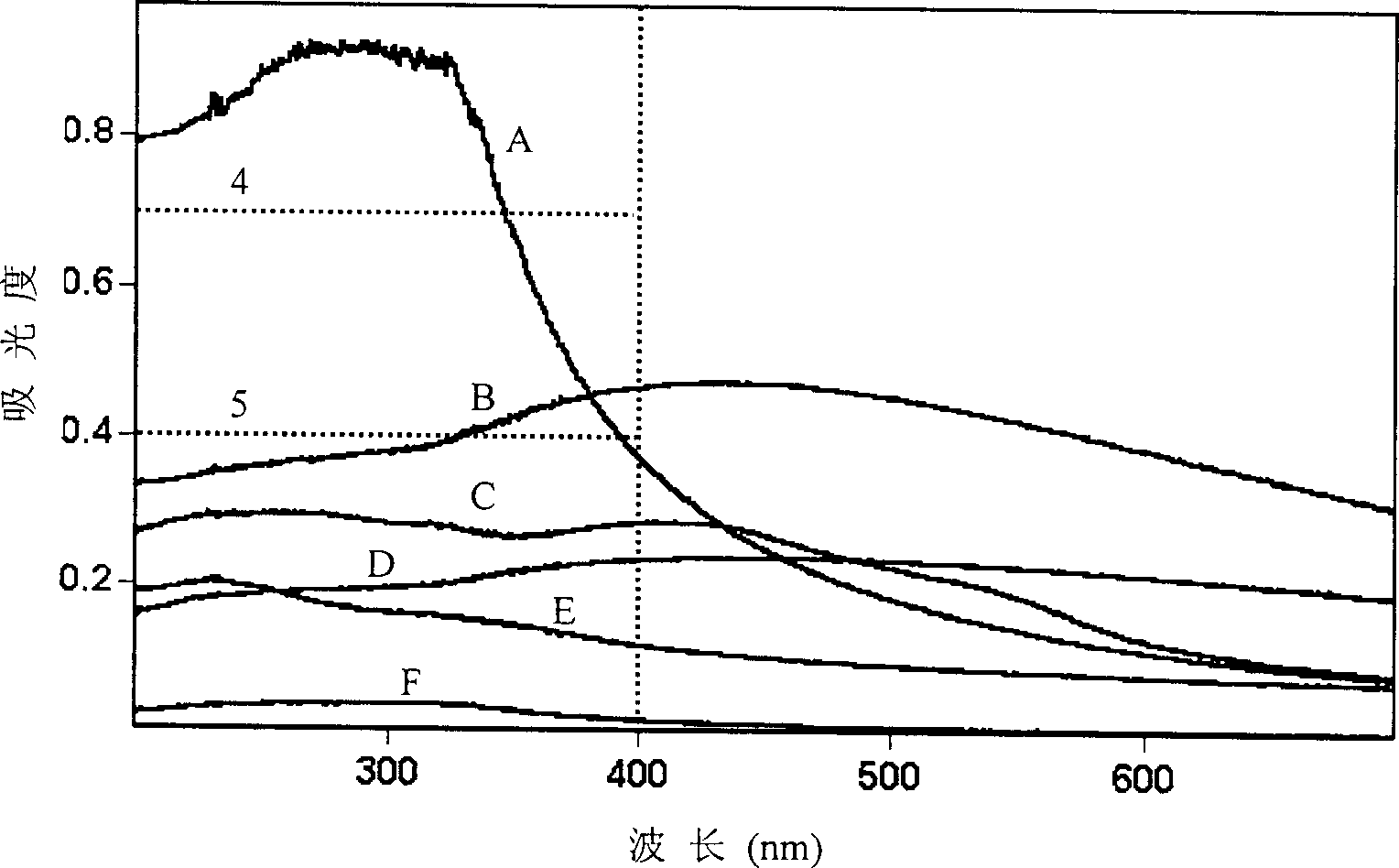

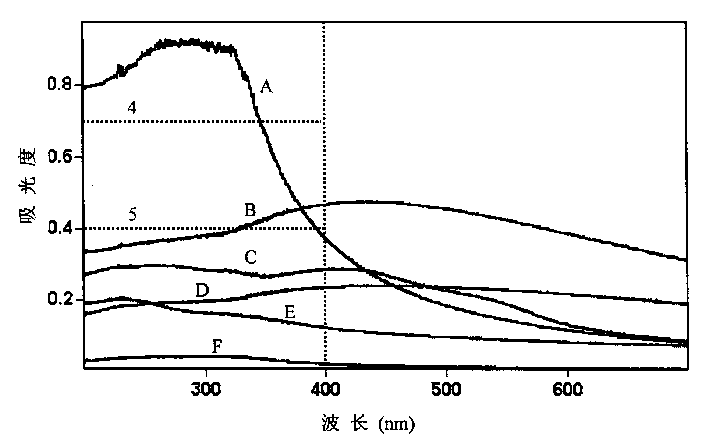

[0028] The nano powder material to be evaluated is P25 nano TiO produced by Germany Degussa company 2 , and its specific technical indicators are: the particle size is 21nm, and the BET surface area is 50±15m 2 / g, crystal form is 80% anatase phase, 20% rutile phase; preparation method, gas phase method.

[0029] Utilize method provided by the invention and Varian, Cary 50 Probe type ultraviolet-visible spectrophotometer, record the ultraviolet shielding curve of this material as figure 2 (A) shown. The scanning results show that the material has a very high platform in the ultraviolet region, the maximum absorbance value A is 0.79, and the ultraviolet shielding performance of the material is evaluated as excellent.

Embodiment 2

[0031] The nano powder material to be evaluated is CFA-TiO provided by a domestic company 2 Nano powder material, the material particle size is 90nm, and the crystal form is rutile mineral phase.

[0032] Utilize method provided by the invention and Varian, Cary 50 Probe type ultraviolet-visible spectrophotometer, record the ultraviolet shielding curve of this material as figure 2 (B) shown. The scanning results show that the maximum absorbance value A of the material in the ultraviolet region is 0.47, and the ultraviolet shielding performance of the material is evaluated as a qualified level.

Embodiment 3

[0034] The nano powder material to be evaluated is nano Fe 2 o 3 . The particle size is 48nm.

[0035] Utilize method provided by the present invention and Varian, Cary 50 Probe type ultraviolet-visible spectrophotometer, record this material ultraviolet shielding curve as figure 2 (C) shown. The scanning results show that the maximum absorbance value A of the material in the ultraviolet region is 0.30, and the ultraviolet shielding performance of the material is evaluated as a poor level.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com