Production method of corn fiber colored spun yarn jacquard pattern bed product fabric

Technology of a kind of corn fiber, production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

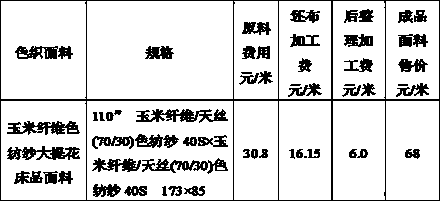

Image

Examples

Embodiment Construction

[0015] The production method of a corn fiber melange yarn jacquard bedding fabric in this embodiment includes (1) raw materials: 14.6tex melange yarn × colored corn fiber with a ratio of colored corn fiber and tencel fiber of 7:3 and 14.6tex colored spun yarn with a ratio of Tencel fiber of 7:3; the warp and weft density is: 681 threads / 10cm×335 threads / 10cm, and the width is 279cm;

[0016] (2) Weaving production:

[0017] Among them, warp yarn: raw material unpacking inspection, winding, warping, sizing and drawing in;

[0018] Weft yarn: raw material unpacking inspection;

[0019] Pattern: Design the pattern, lay the tissue and generate the plate; then weave and weave;

[0020] Among them, the temperature of the sizing tank is controlled at 80°C to 85°C when sizing the colored spinning yarn, and the temperature of the drying cylinder is less than or equal to 100°C; and the sizing process route of "medium speed, small tension, and low temperature" is adopted; the sizing fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com