Composite underground anti-seepage isolation wall structure and construction method

A construction method and separation wall technology, applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve problems such as shortened service life, easy breakdown of barriers, and limited application range, so as to reduce leaching and prevent physical damage , to ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

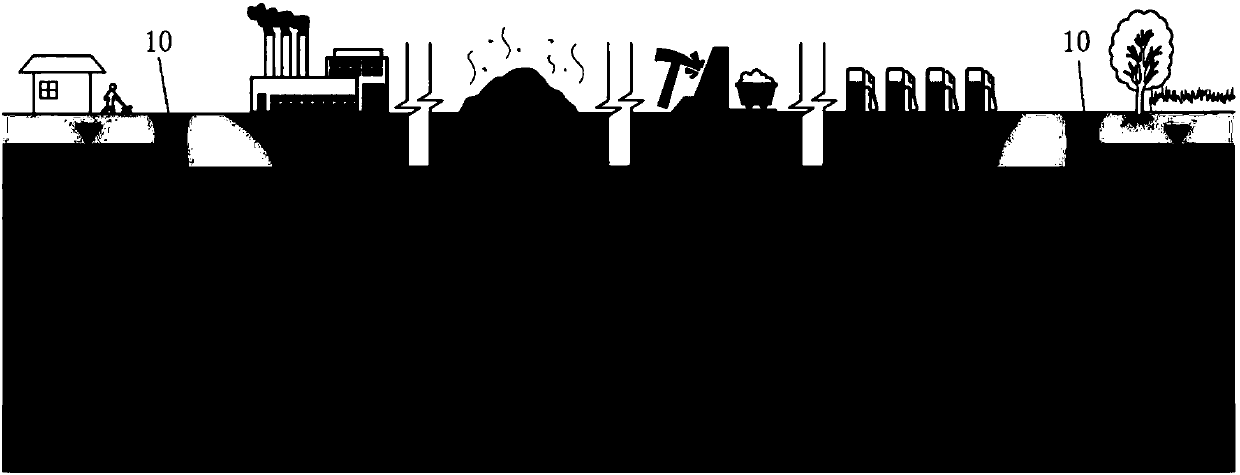

[0042] Refer to attached Figure 4 , a composite underground anti-seepage partition wall structure in this embodiment, it comprises a vertically arranged wall body 1, at least two layers of functional layers 2 arranged in the wall body 1, and the setting direction of the functional layer 2 is the same as that of the wall body 1 parallel, at least one functional layer 2 is plate-shaped. The materials used for each functional layer 2 are different. attached Figure 4 The middle arrow indicates the direction of pollutant penetration.

[0043] In a more preferred embodiment, all the functional layers 2 can be made of plate-shaped materials, or both film-shaped materials a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com