Fiber grating torsional vibration sensor based on the principle of inertia

A fiber grating and sensor technology, which is applied in the direction of using inertial force for acceleration measurement, instruments, measurement devices, etc., can solve the problems of being susceptible to electromagnetic interference, signal distortion, and complicated wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

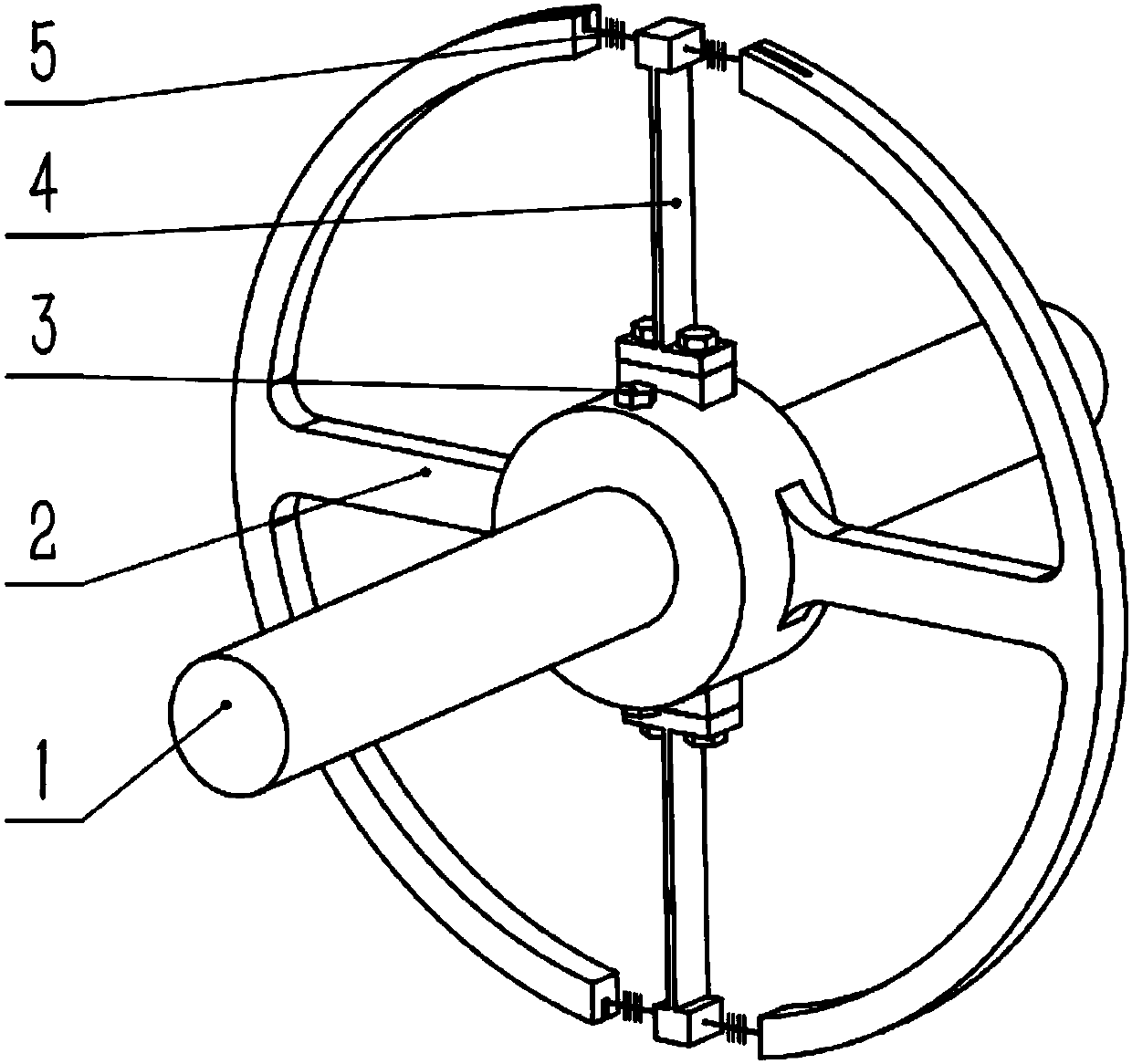

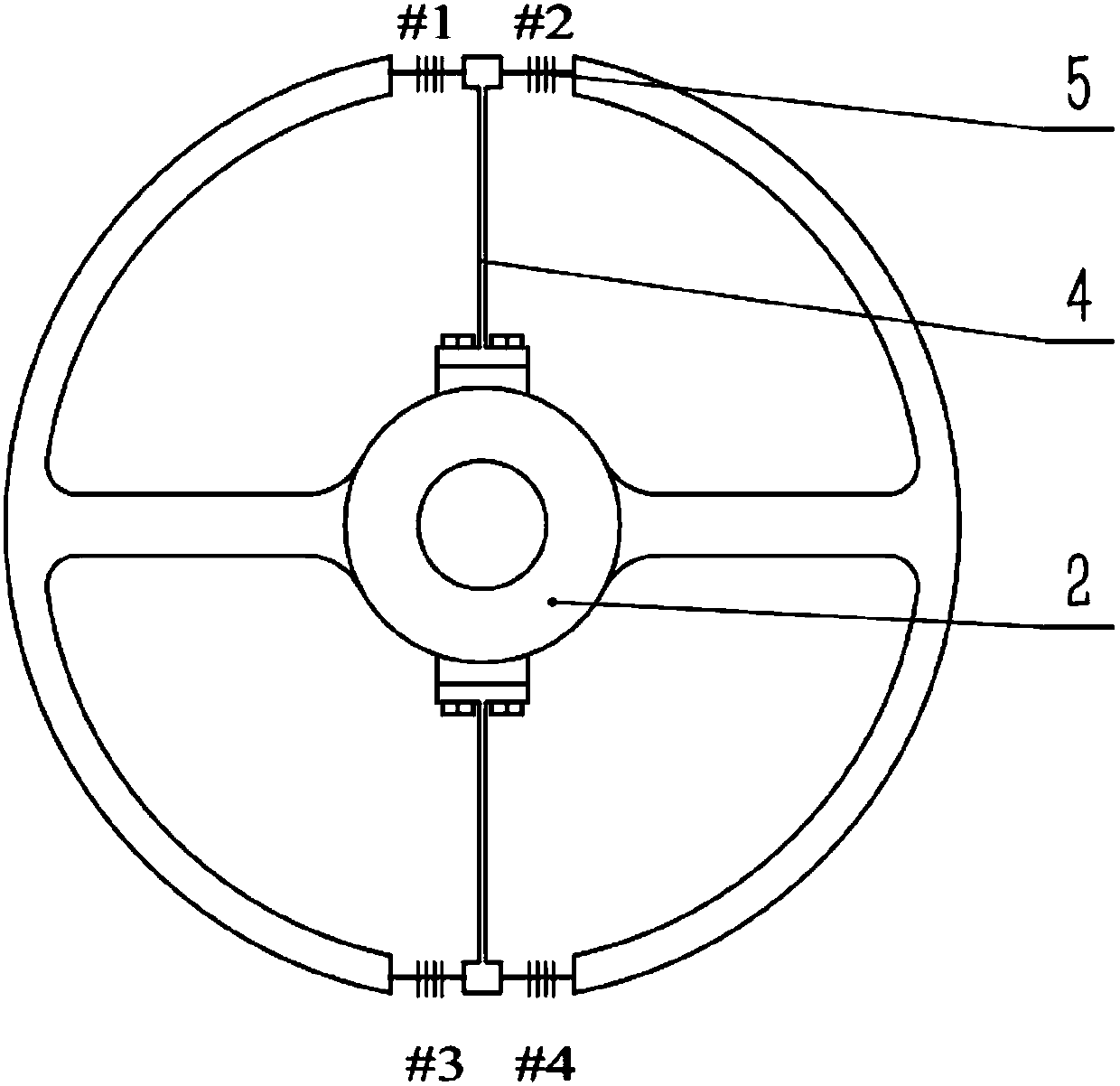

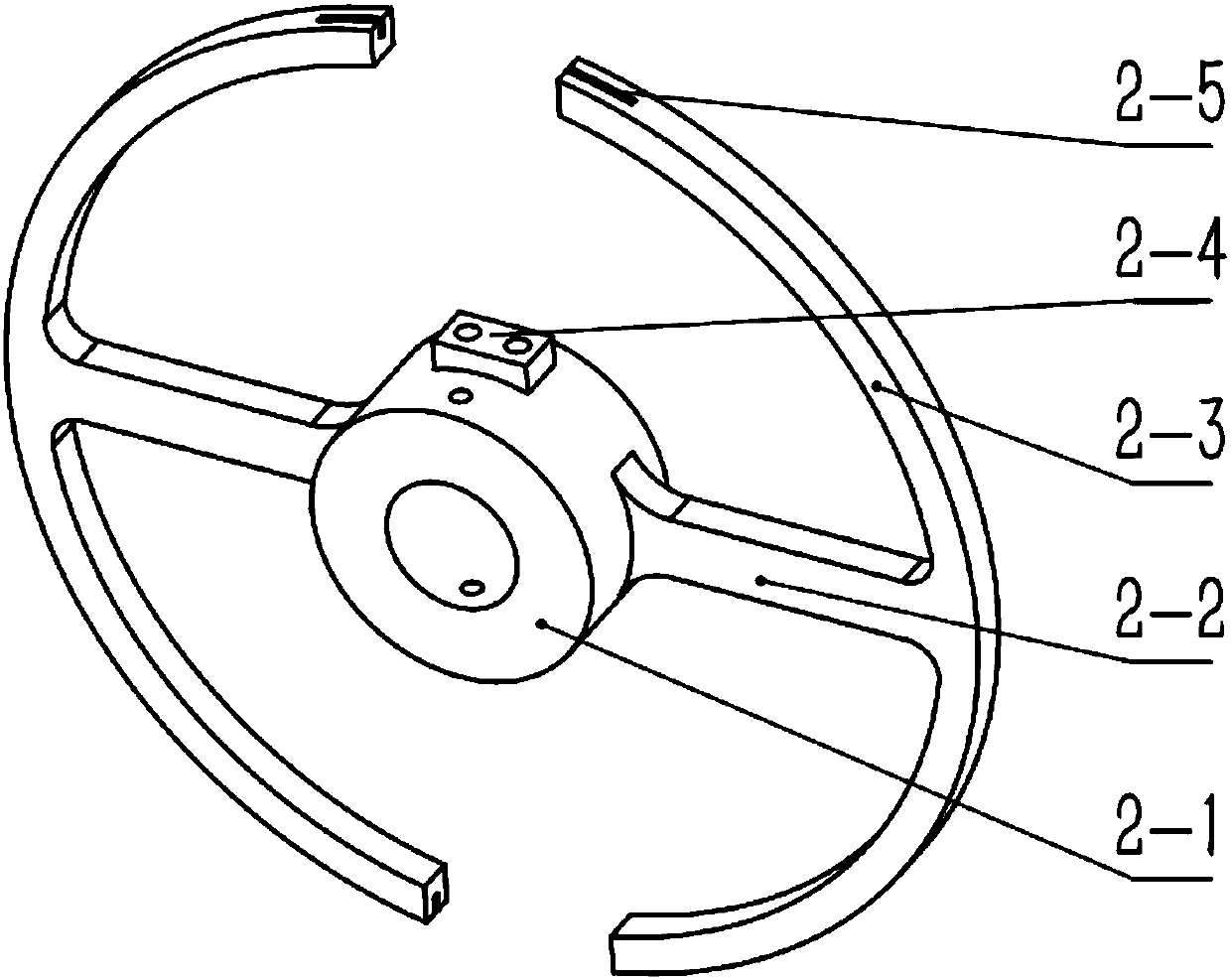

[0019] Such as Figure 1 to Figure 4 As shown, a fiber grating 5 torsional vibration sensor based on the principle of inertia includes a base 2, two assemblies 4 and four fiber gratings 5, the base 2 includes a collar 2-1 for cooperating with the rotating shaft 1, two An optical fiber fixing ring 2-3 concentric with the collar 2-1 and symmetrical to each other and two connecting plates 2-2, the two connecting plates 2-2 are on a straight line and one end is connected with the outer circle of the collar 2-1, The other end is connected to the midpoint of the fiber fixing ring 2-3 itself, and the assembly 4 includes a base 4-2, a constant-section beam 4-3 and a quality block 4-4 connected in sequence, and the two assemblies 4 form two The center of symmetry of an optical fiber fixing ring 2-3, the bases 4-2 of the two assemblies 4 are respectively fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com