Variable-density porous metal orthopedic implant preparation method based on topology optimization technology

A technology for orthopedic implants and topology optimization, applied in image data processing, special data processing applications, instruments, etc., can solve problems such as complex geometry, achieve the effects of reducing stress shielding, minimizing bone resorption, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The purpose of the invention will be further described in detail below in conjunction with the drawings and specific embodiments. The embodiments cannot be repeated here, but the implementation of the invention is not limited to the following embodiments.

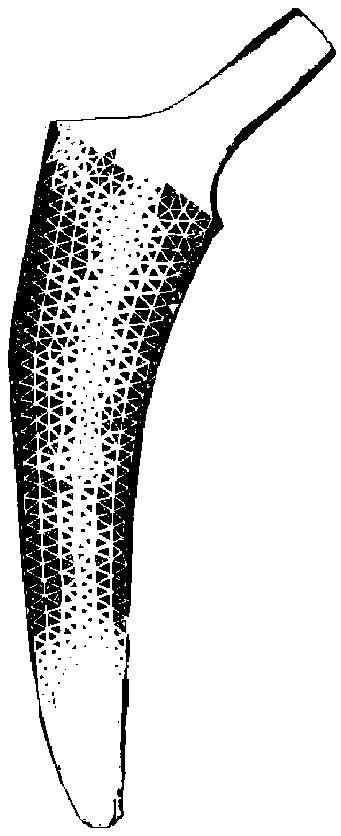

[0034] The following is a hip implant (see figure 1 ) Is described as an example, but the present invention is not limited to hip joint implants, and is also applicable to other orthopedic implants.

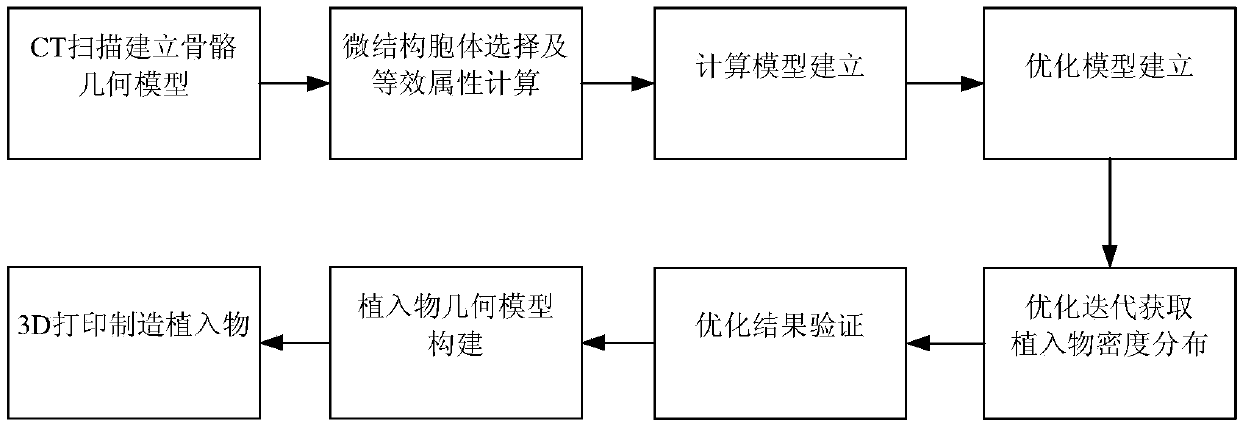

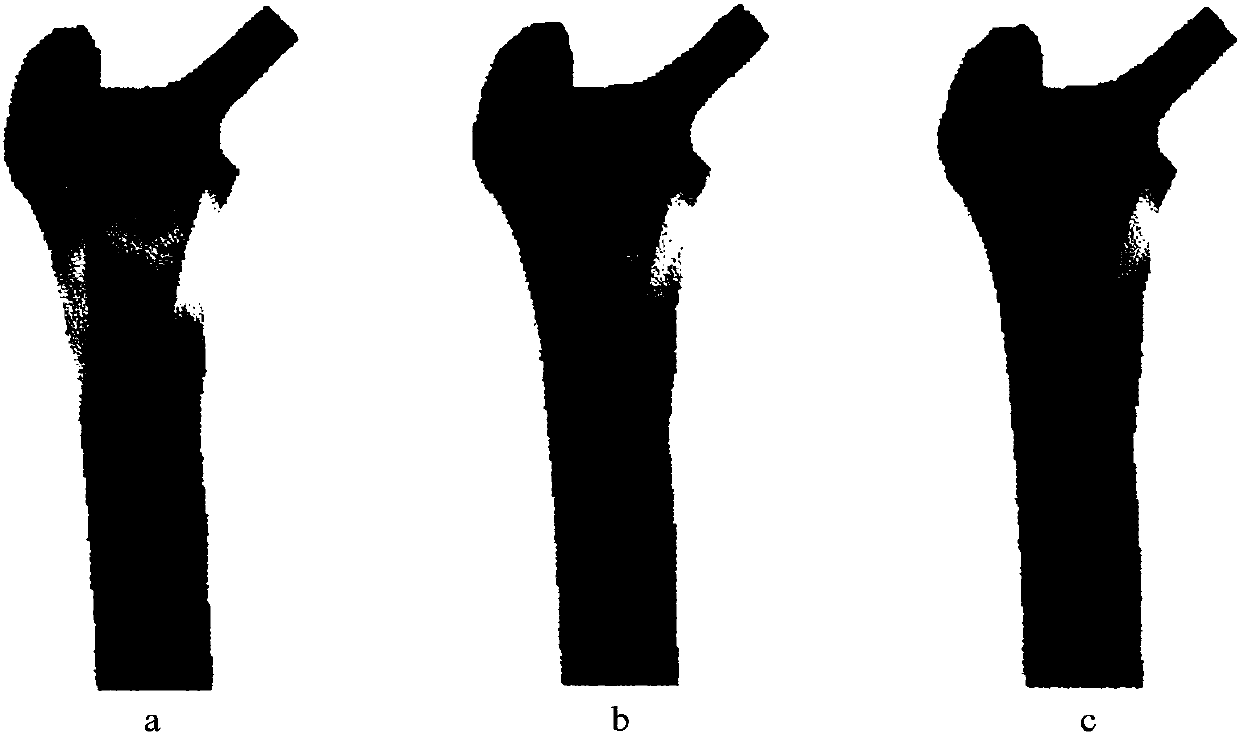

[0035] Such as figure 2 As shown, the method for preparing a variable density porous metal orthopedic implant based on topology optimization technology includes the steps:

[0036] CT scan to establish the skeletal geometry model of the hip joint and select the microstructure, taking porosity, microstructure pore size, and microstructure wall thickness as constraints for topology optimization;

[0037] Calculate the properties of the equivalent solid element by the homogenization method, and use the finite element to calculate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com