Array jet and solid-liquid phase change coupling-based electronic device heat dissipation method

A technology of array jets and electronic devices, applied in cooling/ventilation/heating transformation, etc., can solve the problems of unstable gas-liquid phase transition process, large system pressure drop power consumption, high sealing requirements, etc., and achieve stable heat exchange mode. , the effect of increasing the equivalent heat capacity and improving the heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

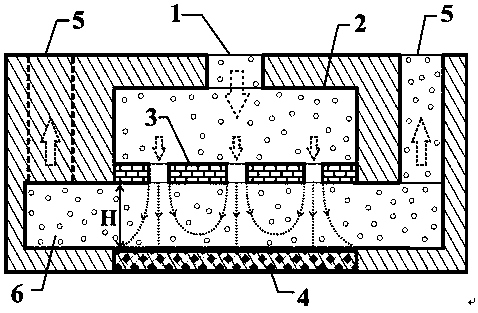

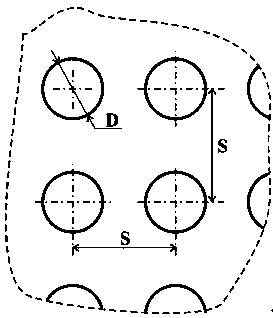

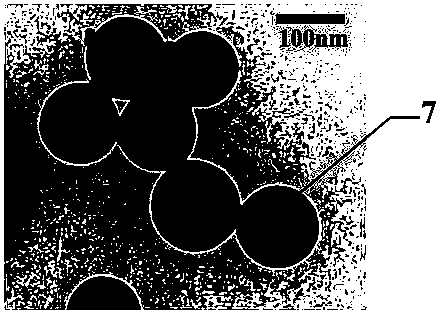

[0037] Such as figure 1 shown. The heat transfer performance is studied through two-dimensional numerical simulation. The physical model of the present invention adopts an array jet structure composed of three groups of nozzles. The nozzle diameter D is 1mm, the array hole spacing S is 5mm, and the jet spacing H is 10mm. The mobile working medium considers pure water and phase change nanocapsule suspension respectively for comparative test, wherein the volume percentage of phase change nanocapsule particles 7 in the phase change nanocapsule suspension is 28%, and the phase change capsule core in a single phase change nanocapsule particle The mass percentage is 48.6%, the average diameter of the capsule particles is 100nm, the latent heat of phase change of the suspension is 31.2kJ / kg, the phase change temperature range is 27-29°C, the volume flow rate of a single nozzle is 0.94L / min, the heating surface The heat flux is 400W / cm 2 .

[0038] Figure 5 is the temperature dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com