Cooked food vacuum cooling device capable of adjusting vacuum degree and stabilizing pressure

A technology of vacuum cooling and vacuum degree, applied in the fields of food preservation, food science, application, etc., can solve the problems of low final temperature of product cooling or low vacuum degree, damaged product quality or quality, and unadjustable vacuum degree, etc., to protect the vacuum pump. , the effect of reducing quality loss or quality loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

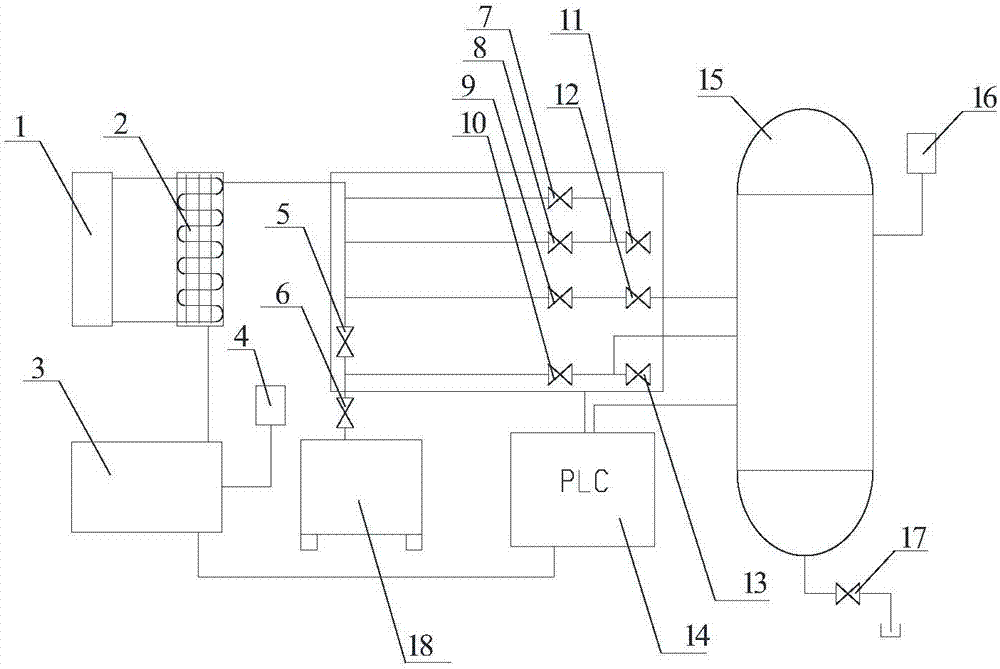

[0011] Such as figure 1 As shown, a vacuum cooling device for cooked food that can adjust the vacuum degree and stabilize the pressure of the present invention includes a refrigeration unit 1, a cold trap 2, a vacuum tank 3, a vacuum gauge 4, a vacuum isolation valve 5, an electromagnetic belt inflation valve 6, Trim valve 17, trim valve 2 8, solenoid valve 1 9, solenoid valve 2 10, micro-return solenoid valve 11, regulating valve 12, re-pressure valve 13, PLC controller 14, vacuum accumulator 15, vacuum gauge 2 16 , Drain solenoid valve 17, vacuum pump 18.

[0012] The vacuum tank 3 is connected with the cold trap 2; the vacuum tank 3 is equipped with a vacuum gauge-4; the cold trap 2 is connected with the refrigeration unit 1; The pipeline is connected with the cold trap 2; the vacuum accumulator 15 is equipped with a vacuum gauge two 16, and the vacuum accumulator 15 lower end is equipped with a drainage solenoid valve 17; the PLC controller 14 is connected with each contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com