Method for regenerating catalyst for synthesizing o-chloroaniline

A technology of o-chloroaniline and catalyst, applied in the field of catalyst regeneration, can solve problems such as inconvenience in actual operation, and achieve the effects of improving regeneration efficiency and utilization rate, optimizing process design, and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

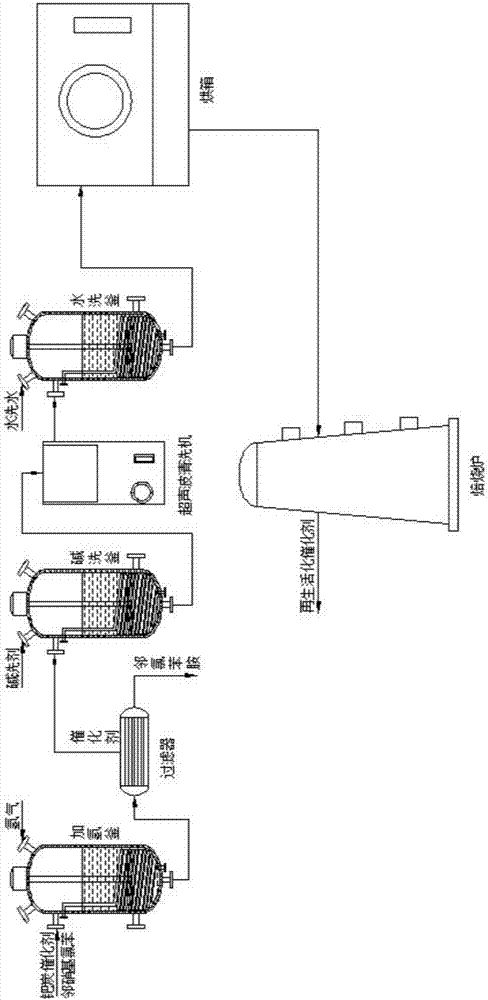

[0026] see figure 1 Shown, the technical scheme that the present invention adopts is: a kind of regeneration method that is used for the catalyst that reduction method makes o-phenylenediamine, and the regeneration method of described catalyst specifically comprises the following steps:

[0027] (1). Filtration: The hydrogenation catalyst is filtered out from the catalyst filter installed in the final stage kettle of the four-stage series hydrogenation kettle for the hydrogenation reaction of o-phenylenediamine, and the filtered hydrogenation catalyst enters the alcohol washing kettle ;

[0028] (2). Alcohol washing: introduce the hydrogenation catalyst filtered from the filter into the alcohol washing tank, add the alcohol washing reagent, set the stirring rate of the agitator on the alcohol washing tank and the alcohol washing temperature in the alcohol washing tank, and turn on Carry out alcohol washing after the mixer;

[0029] (3). Ultrasonic cleaning: introduce the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com