High-temperature depainting device for discarded zip-top cans, and depainting method

A technology for discarding cans and stripping paint, which is applied in the removal of solid waste and other directions, can solve the problem of inability to remove the carbides on the surface of the cans, and achieve the effects of shortening the treatment time, simplifying the recycling process and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Step 1. Clean the discarded pop cans, cut them into discs with a diameter of 0.5 cm, conduct thermogravimetric analysis on the discarded pop cans discs, and determine that the temperature range for high-temperature paint removal is within the range of 20°C to 650°C;

[0067] Step 2. Cut the discarded cans into pieces of 3cm×3cm and clean them. During the cleaning process, add detergent and stir to remove sugar stains and dust remaining on the surface of the discarded cans. Dry the cleaned pieces at a temperature of 80°C. Dried, remove the moisture and set aside.

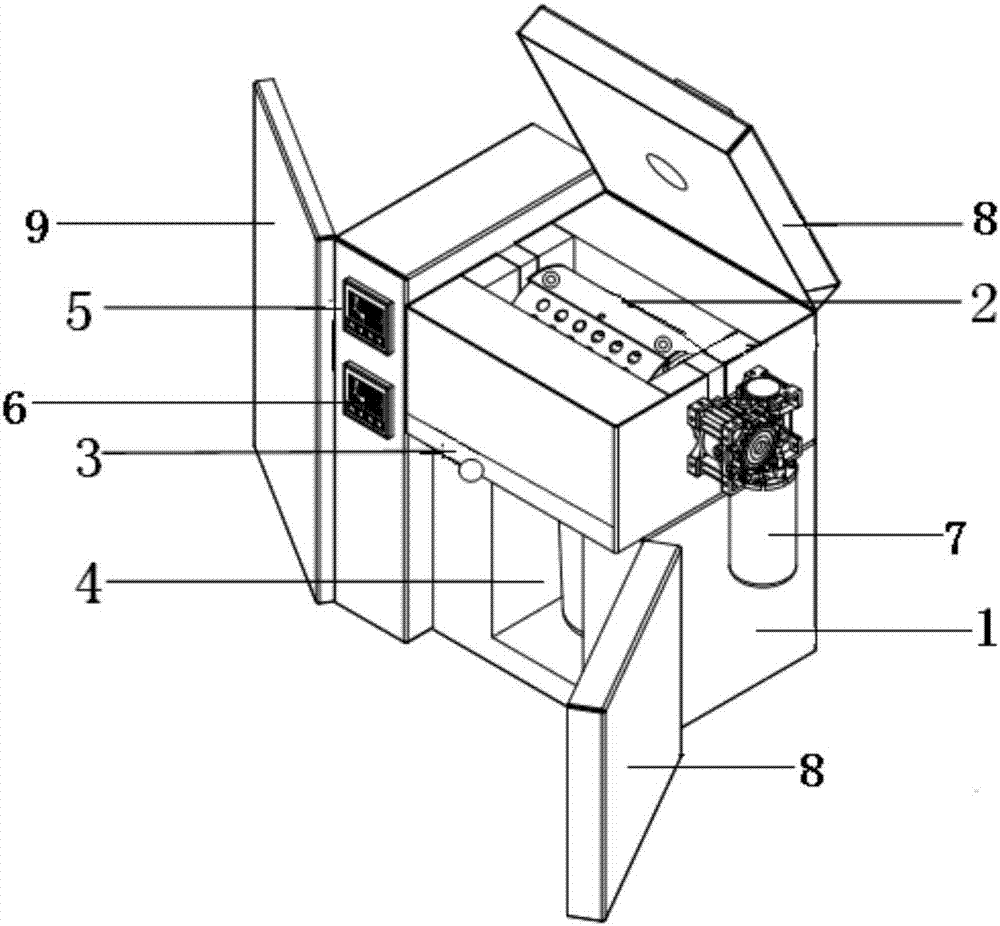

[0068] Step 3. Weigh the discarded pop can fragments after the pretreatment in step 2, and record it as M 1 , and then place it in the rotary reaction chamber 2 for high-temperature paint removal treatment;

[0069] Wherein, the high-temperature paint stripping temperature is 500° C., and the paint stripping time is 20 minutes.

[0070] Step 4. Rotate and oscillate the rotary reaction chamber 2 in step 3, os...

Embodiment 2

[0075] Step 1. Clean the discarded pop cans, cut them into discs with a diameter of 0.5 cm, conduct thermogravimetric analysis on the discarded pop cans discs, and determine that the temperature range for high-temperature paint removal is within the range of 20°C to 650°C;

[0076] Step 2. Cut the discarded cans into pieces of 3cm×3cm and clean them. During the cleaning process, add detergent and stir to remove sugar stains and dust remaining on the surface of the discarded cans. Dry the cleaned pieces at a temperature of 80°C. Dried, remove the moisture and set aside.

[0077] Step 3. Weigh the discarded pop can fragments after the pretreatment in step 2, and record it as M 1 , and then place it in the rotary reaction chamber 2 for high-temperature paint removal treatment;

[0078] Wherein, the high-temperature paint stripping temperature is 520° C., and the paint stripping time is 20 minutes.

[0079] Step 4. Rotate and oscillate the rotary reaction chamber 2 in step 3, os...

Embodiment 3

[0085] Step 1. Clean the discarded pop cans, cut them into discs with a diameter of 0.5 cm, conduct thermogravimetric analysis on the discarded pop cans discs, and determine that the temperature range for high-temperature paint removal is within the range of 20°C to 650°C;

[0086] Step 2. Cut the discarded cans into pieces of 3cm×3cm and clean them. During the cleaning process, add detergent and stir to remove sugar and dust remaining on the surface of the discarded cans. Dry the cleaned pieces at 100°C Dried, ready to use after removing water;

[0087] Step 3. Weigh the discarded pop can fragments after the pretreatment in step 2, and record it as M 1 , and then place it in the rotary reaction chamber 2 for high-temperature paint removal treatment;

[0088] Among them, the high-temperature paint stripping temperature is 540° C., and the paint stripping time is 20 minutes.

[0089] Step 4. Rotate and oscillate the rotary reaction chamber 2 in step 3, oscillate the surface c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com