Pre-mixed fluidized stabilized soil

A technology of solidifying soil and fluid state, applied in the field of civil engineering and building materials, can solve the problems of difficulty in forming foundation pit supporting curtain walls, waste of land and soil resources, secondary pollution of the surrounding environment, etc., and has great potential for later strength development. , saving resources and avoiding the effect of secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: according to the following proportioning, prepare ready-mixed fluid solidified soil:

[0020] water 15%

[0021] Soil 77%

[0022] Composite curing material 2.67%

[0023] Cement 5.33%

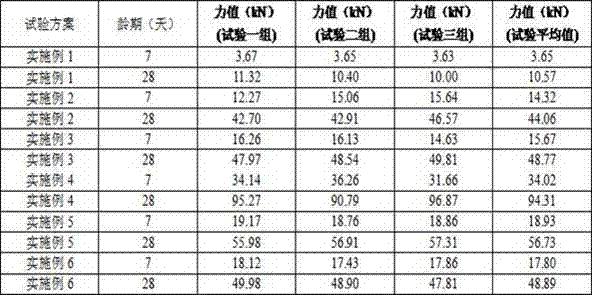

[0024] Compressive strength test: Static pressure test is adopted at the optimum water content, the compaction degree is 96%, and the curing system is standard curing: see Table 1 for the strength achieved during the curing age of 7 days and 28 days.

Embodiment 2

[0025] Embodiment 2: according to following proportioning, prepare ready-mixed fluid solidified soil:

[0026] water 15%

[0027] Soil 70%

[0028] Composite curing material 5%

[0029] Cement 10%

[0030] The experimental materials of this embodiment are the same as those of Embodiment 1, but differ in mass ratio. Compressive strength test: Static pressure test is adopted at the optimum water content, the compaction degree is 96%, and the curing system is standard curing: see Table 1 for the strength achieved during the curing age of 7 days and 28 days.

Embodiment 3

[0031] Embodiment 3: according to following proportioning, prepare ready-mixed fluid solidified soil:

[0032] water 15%

[0033] Soil 65%

[0034] Composite curing material 6.7%

[0035] Cement 13.3%

[0036] The experimental materials of this embodiment are the same as those of Embodiment 1, but differ in mass ratio. Compressive strength test: Static pressure test is adopted at the optimum water content, the compaction degree is 96%, and the curing system is standard curing: see Table 1 for the strength achieved during the curing age of 7 days and 28 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com