Production technology of FDN superplasticizer

A high-efficiency water reducer and production process technology, applied in the field of water reducer production process, can solve problems such as product performance impact, and achieve the effects of increasing production rate, saving costs and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

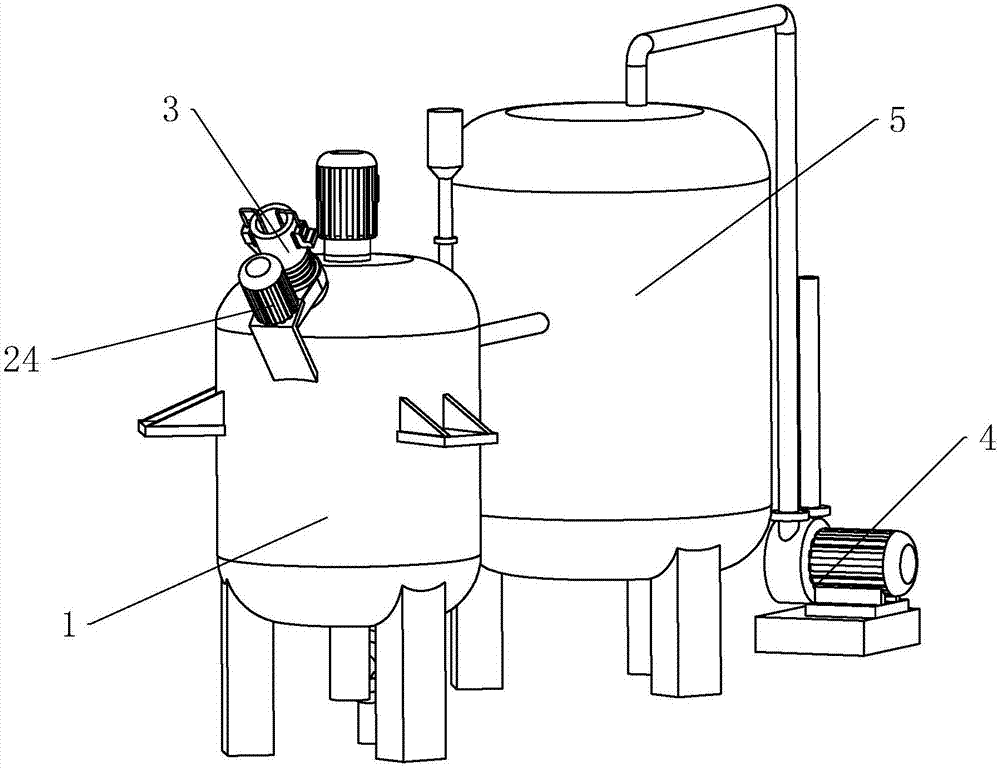

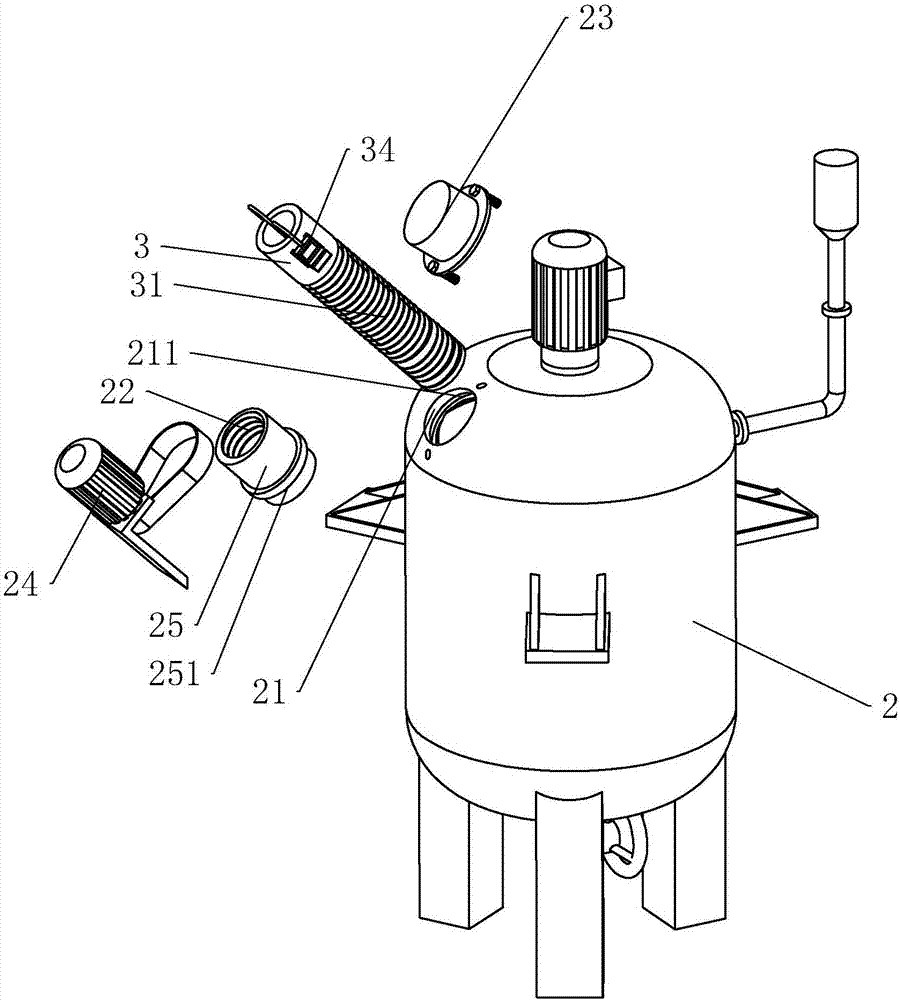

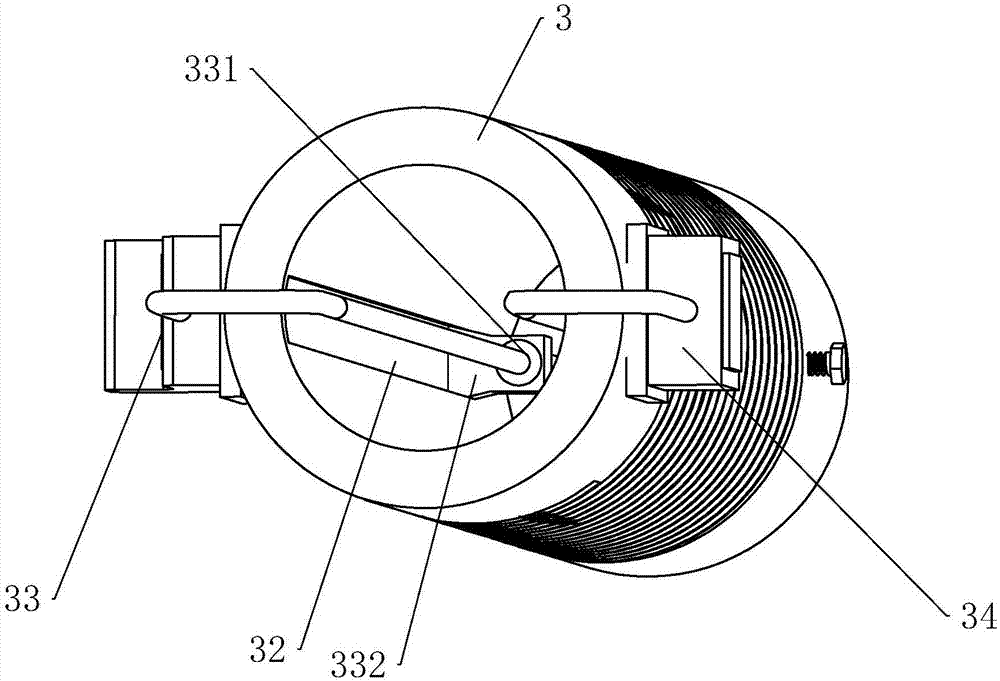

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: a kind of production technology of FDN high-efficiency water reducing agent, comprises the following operation steps:

[0042] 1, sulfonation: drop into the naphthalene raw material of molten state in reaction unit, adjust temperature to 120 ℃, add the concentrated sulfuric acid that mass percentage concentration is 98%, the ratio of the amount of substance of naphthalene raw material and concentrated sulfuric acid is 1:1, and Carry out sulfonation reaction at 160°C with heat preservation, and carry out vacuum distillation during the reaction process to remove excess water in the reaction device to obtain sulfonated material;

[0043] II. Feeding: cool down the sulfonated material to 110-130°C and add waste materials containing polysulfonic acid naphthalene compounds;

[0044] Ⅲ. Condensation: Cool down the reactant in step Ⅱ to 80°C, add metered formaldehyde dropwise, and raise the temperature to 90°C after the dropwise addition, and carry out condensatio...

Embodiment 2

[0050] Example 2: A production process of FDN high-efficiency water reducer, the difference from Example 1 is that in step I, the molten naphthalene raw material is put into the reaction device, the temperature is adjusted to 130 °C, and the mass percentage concentration is added It is 98% concentrated sulfuric acid, the ratio of naphthalene raw material to concentrated sulfuric acid is 1:1.05, and the sulfonation reaction is carried out at 162°C. During the reaction, vacuum distillation is carried out to remove excess water in the reaction device to obtain sulfonate chemicals.

Embodiment 3

[0051] Example 3: A production process of FDN high-efficiency water reducer, the difference from Example 1 is that in step I, the molten naphthalene raw material is put into the reaction device, the temperature is adjusted to 140 °C, and the mass percentage concentration is added It is 98% concentrated sulfuric acid, the ratio of naphthalene raw material to concentrated sulfuric acid is 1:1.1, and the sulfonation reaction is carried out at 165°C. During the reaction, vacuum distillation is carried out to remove excess water in the reaction device to obtain sulfonate chemicals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com