Organic electroluminescence display panel and display device

An electroluminescent display and display panel technology, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as voltage increase, and achieve the effects of low power consumption, long-term stable driving voltage, and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

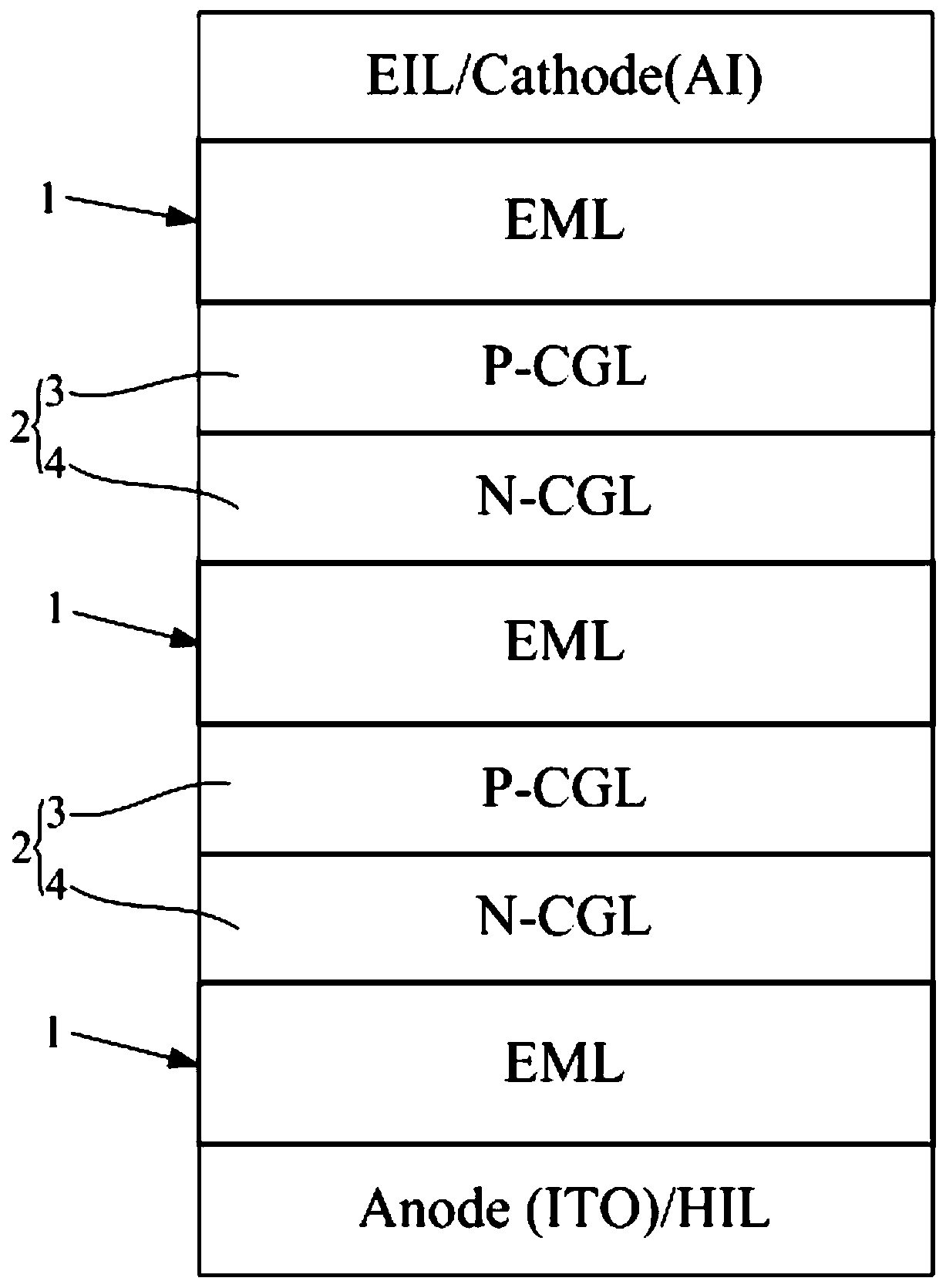

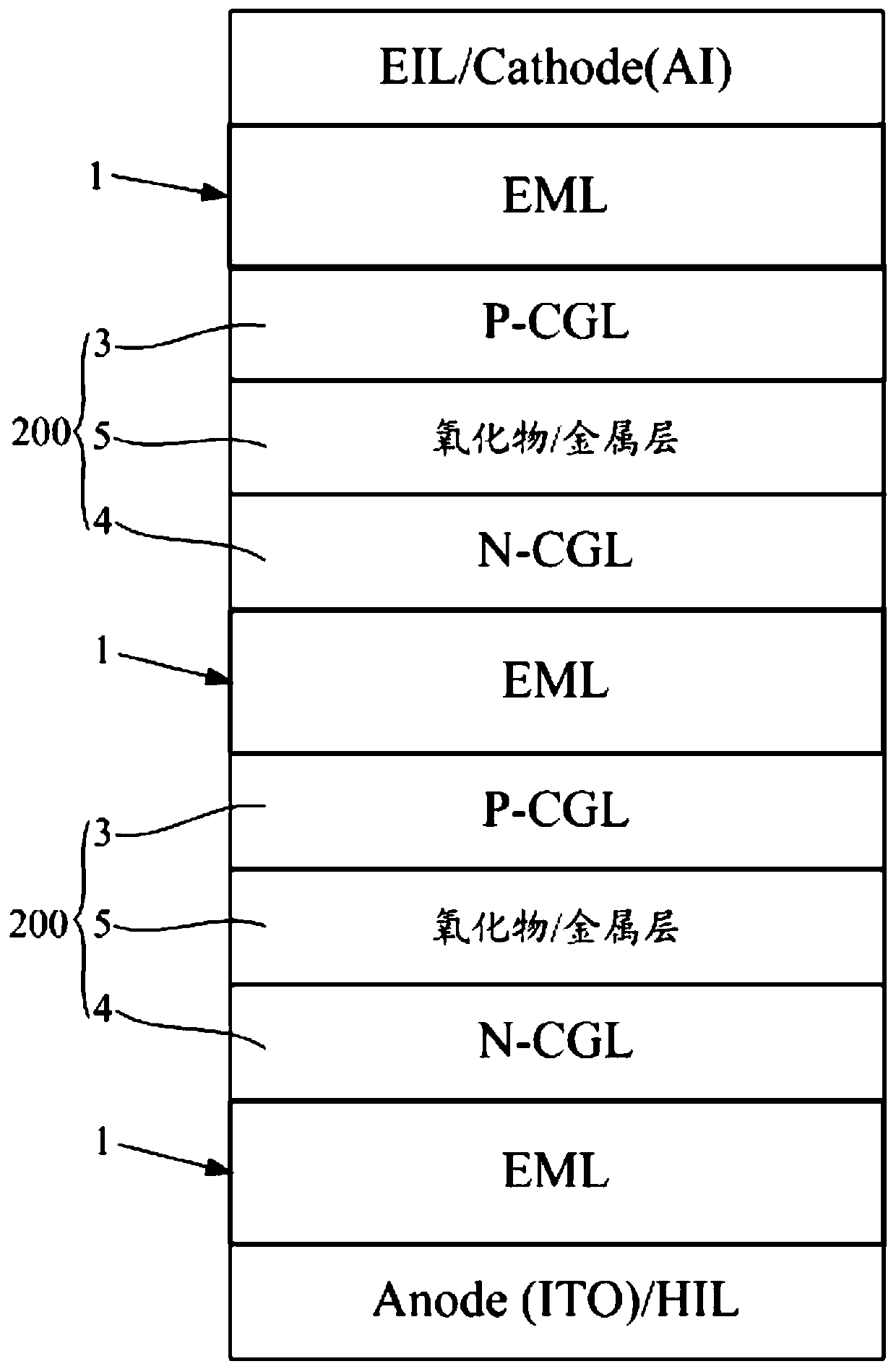

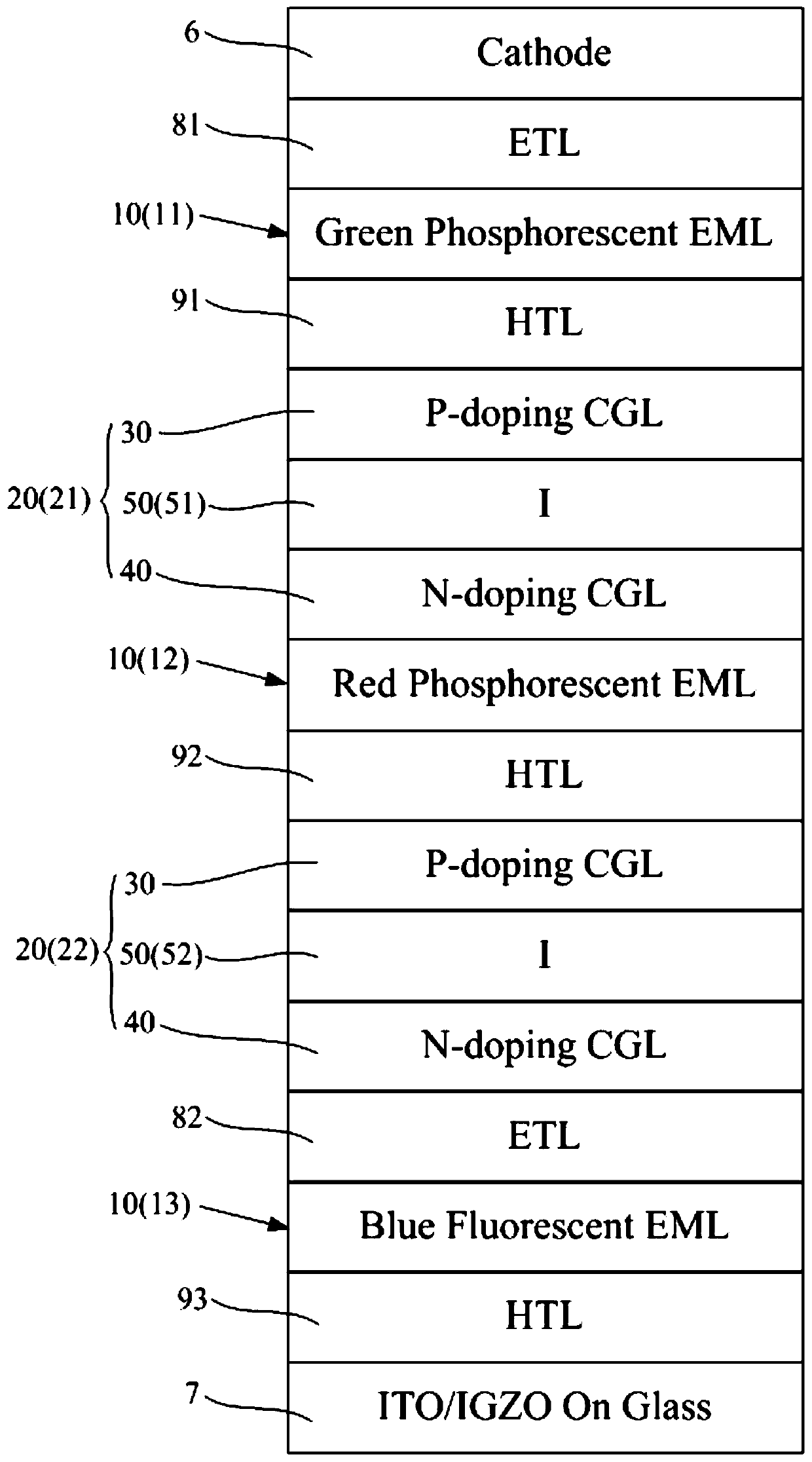

[0057] Embodiment one, such as image 3 As shown, the P-I-N type OLED provided by the embodiment of the present invention may include a first light-emitting unit 11, a second light-emitting unit 12 and a third light-emitting unit 13 connected in series in sequence. The first light-emitting unit 11, the second light-emitting unit 12 and the third light-emitting unit The three light-emitting units 13 can form white light through brightness ratio; optionally, the first light-emitting unit 11, the second light-emitting unit 12 and the third light-emitting unit 13 can be green light-emitting units, red light-emitting units and blue light-emitting units respectively Specifically, a first charge generation layer (P-I-N type CGL) 21 is provided between the first light emitting unit 11 and the second light emitting unit 12, and a second charge generation layer is provided between the second light emitting unit 12 and the third light emitting unit 13 layer (P-I-N type CGL) 22 .

Embodiment approach

[0059] Mode 1, in the first charge generation layer 21, the electron mobility of the intermediate layer (I layer) 51 is greater than the electron mobility of the N-doped layer host material; in the second charge generation layer 22, the electron mobility of the intermediate layer (I layer) 52 The hole mobility is greater than that of the host material of the P-doped layer.

[0060] Mode 2, in the first charge generation layer 21, the hole mobility of the intermediate layer (I layer) 51 is greater than the hole mobility of the P-doped layer host material; in the second charge generation layer 22, the intermediate layer (I layer) The electron mobility of 52 is greater than that of the host material of the N-doped layer.

[0061] Mode 3, in the first charge generation layer 21, the electron mobility of the intermediate layer (I layer) 51 is greater than the electron mobility of the N-doped layer host material; in the second charge generation layer 22, the electron mobility of the...

Embodiment 2

[0063] Embodiment two, such as Figure 4 As shown, the P-I-N type CGL OLED panel provided by the embodiment of the present invention may include two light-emitting units 10 connected in series, that is, the light-emitting unit 14 and the light-emitting unit 15. The light-emitting unit 14 and the light-emitting unit 15 can form white light through brightness ratio Optionally, the light-emitting unit 14 and the light-emitting unit 15 can be respectively a yellow light-emitting unit and a blue light-emitting unit; specifically, a charge generation layer (P-I-N type CGL) 23 is provided between the light-emitting unit 14 and the light-emitting unit 15, the In the charge generation layer (P-I-N type CGL) 23, the electron mobility of the intermediate layer (I layer) 53 is greater than the electron mobility of the host material of the N-doped layer 40; and / or, the hole mobility of the intermediate layer (I layer) 53 The rate is greater than the hole mobility of the host material of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com