Preparation and use of stable citrus aurantium flower flavor tobacco essence

A tobacco flavor and stable technology, which is applied in the field of preparation of stable orange blossom flavor tobacco flavor, can solve the problems of uneven flavor release, achieve uniform flavor release, increase sweetness and bottom flavor, and improve the quality of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

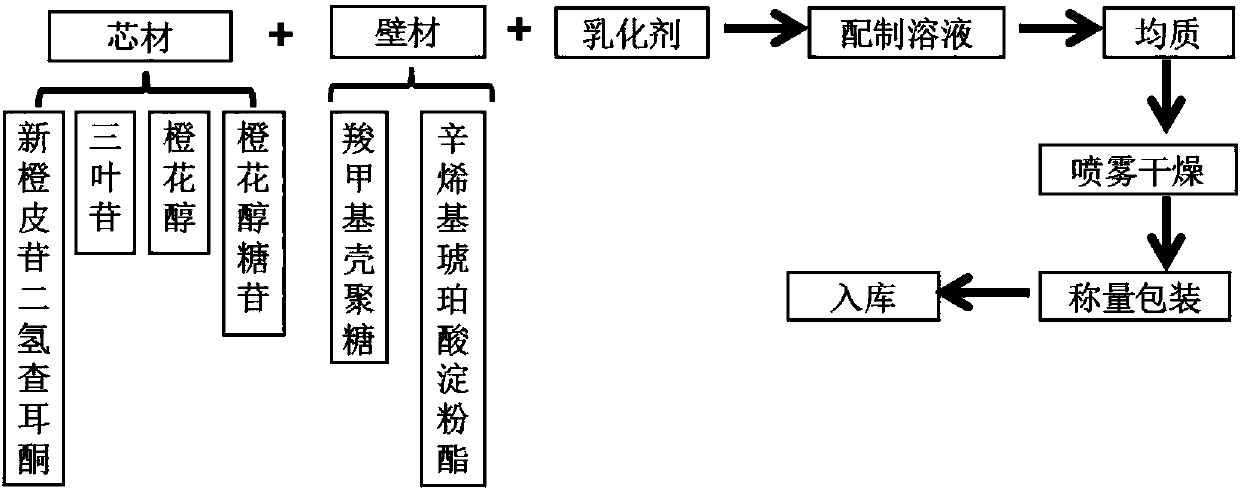

Method used

Image

Examples

Embodiment 1

[0026] Weigh 1 part by weight of neohesperidin dihydrochalcone, 1 part by weight of trilobatin, 10 parts by weight of nerolidol, and mix evenly with 10 parts by weight of nerol glycoside; , 60wt% starch octenyl succinate, mixed evenly; mix the two mixtures according to the weight ratio of core material and wall material as 3:1. Weigh 0.5wt% sodium stearoyl lactylate accounting for the total weight of the wall material and the core material and mix it with the wall material core material; add water to the mixture and stir to prepare a 30wt% aqueous dispersion; homogenize at 60°C and 20MPa to obtain a uniform water Dispersion liquid; spray drying to obtain the stable flavor for tobacco. Tobacco essence is added to the tobacco, and the cigarette is rolled after balancing.

Embodiment 2

[0028] Weigh 2 parts by weight of neohesperidin dihydrochalcone, 1 part by weight of trilobatin, 5 parts by weight of nerol, and 5 parts by weight of nerol glucoside and mix uniformly; , 70wt% starch octenyl succinate, mixed evenly; mix the two mixtures according to the weight ratio of core material and wall material as 2:1. Weigh 1.0wt% sodium stearoyl lactylate accounting for the total weight of the wall material and the core material and mix it with the wall material core material; add water to the mixture and stir to prepare a 35wt% aqueous dispersion; homogenize at 70°C and 25MPa to obtain a uniform water Dispersion liquid; spray drying to obtain the stable flavor for tobacco. Tobacco essence is added to the tobacco, and the cigarette is rolled after balancing.

Embodiment 3

[0030] Weigh 2 parts by weight of neohesperidin dihydrochalcone, 2 parts by weight of trilobatin, 4 parts by weight of nerol, and 4 parts by weight of nerol glucoside and mix uniformly; , 50wt% starch octenyl succinate, mixed evenly; mix the two mixtures according to the weight ratio of the core material and the wall material as 1:1. Weigh 1.5wt% sodium stearoyl lactylate accounting for the total weight of the wall material and the core material and mix it with the wall material core material; add water to the mixture and stir to prepare a 35wt% aqueous dispersion; homogenize at 60°C and 30MPa to obtain a uniform water Dispersion liquid; spray drying to obtain the stable flavor for tobacco. Tobacco essence is added to the tobacco, and the cigarette is rolled after balancing.

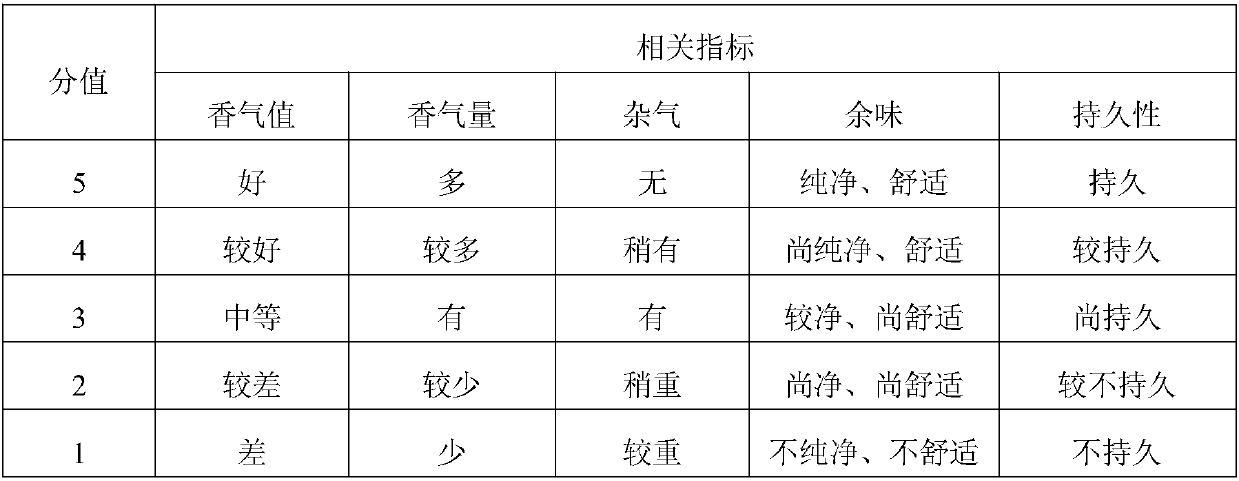

[0031] Using the stable tobacco essence of the present invention to add it to shredded cigarettes, compared with the cigarettes added with common tobacco essence, 10 professionals were selected to evalu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com