Thermally sensitive plant-aromatic controlled-release granules and preparation method thereof

A slow-release granule and heat-sensitive technology, which is applied in food preparation, food science, and pharmaceutical formulations, can solve problems such as fast loss rate, insufficient slow-release and uniform release ability of flavor substances, and poor slow-release ability, so as to increase added value , Adding technology of high-quality fragrance substances and the effect of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

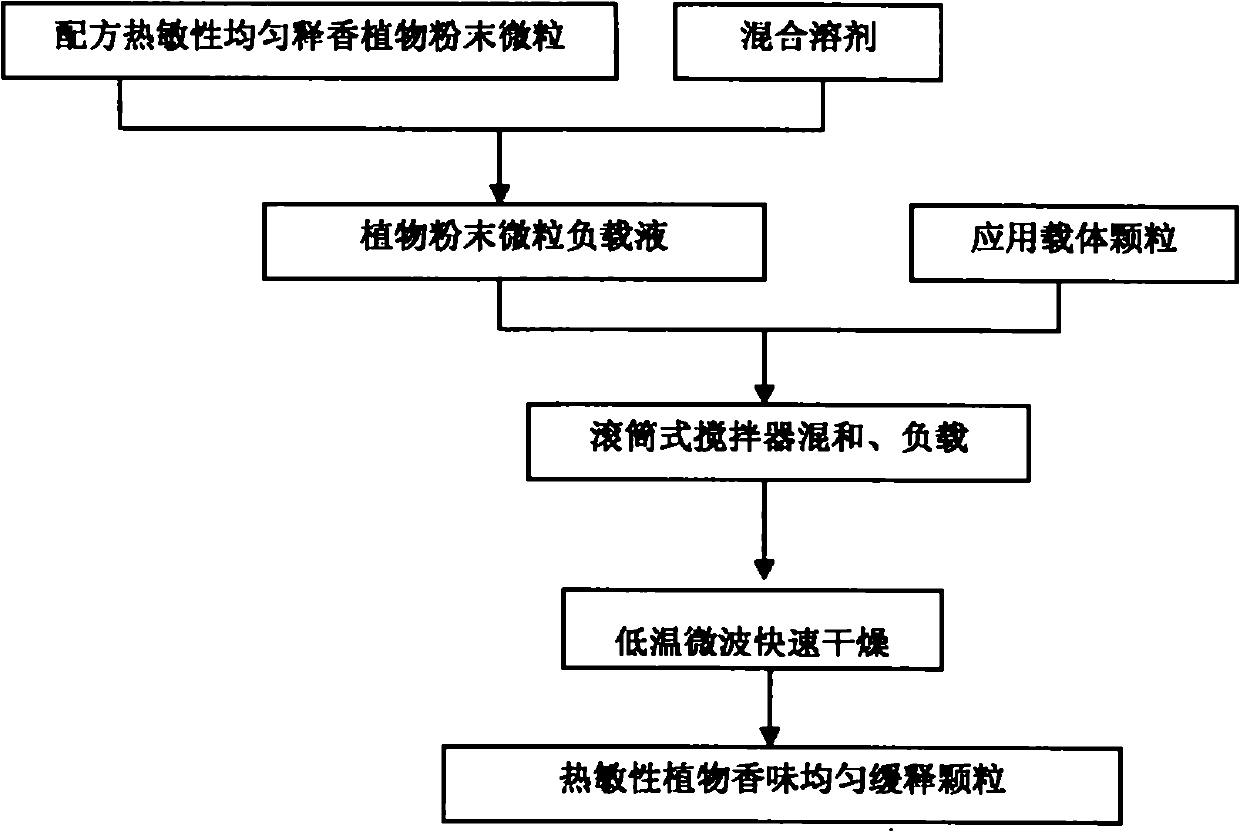

[0033] Preparation of heat-sensitive plant aroma uniform slow-release granules for compound filter of flower-fruit compound flavor cigarette:

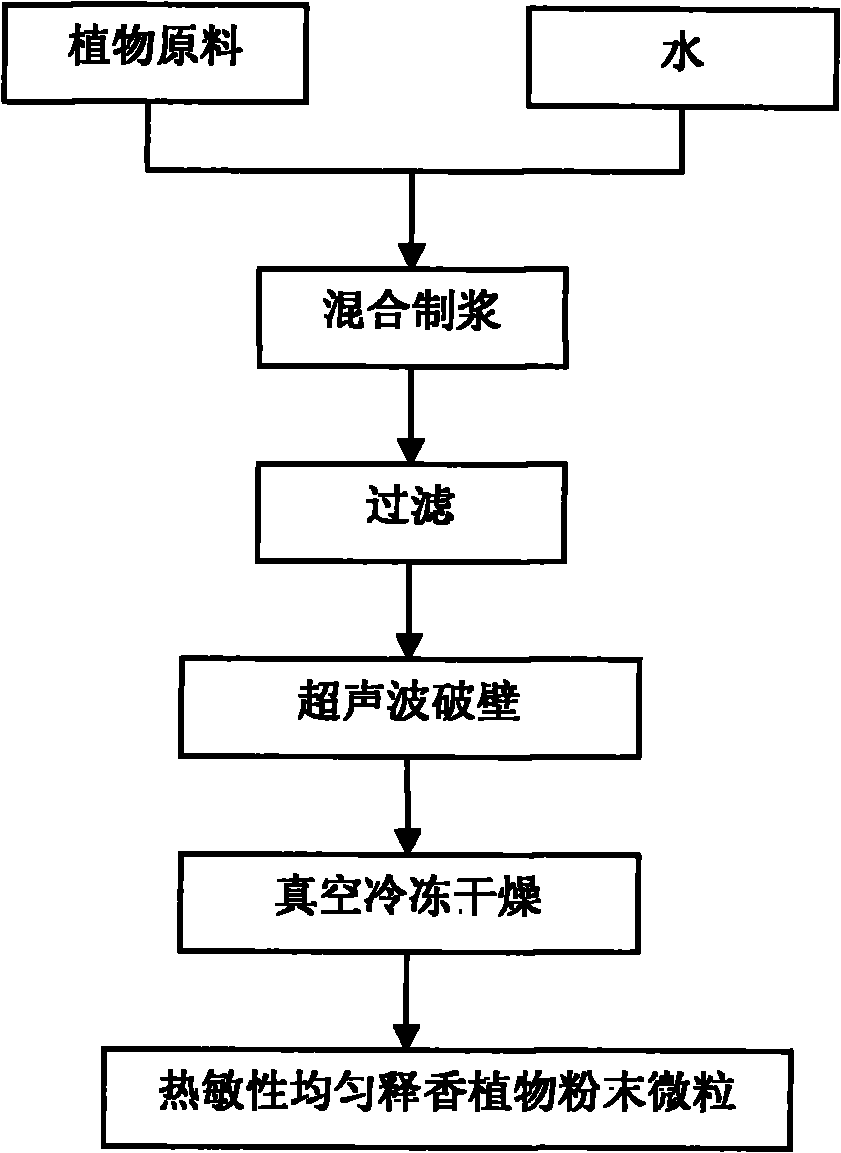

[0034] 1. Fresh rose petals, mint leaves, and strawberries are respectively made into slurry in a refiner according to a solid-to-liquid ratio of 1:10 (mass ratio, the same below), and filtered with a 150-mesh filter cloth. The filtrate was broken using an ultrasonic cell breaker. Ultrasonic frequency: 20KHZ, power: 1200W, processing time: 3min. Pre-freeze the slurry after the wall breaking treatment to -35°C, and then send it to a hot plate vacuum freeze dryer and freeze-dry it at a temperature of -5°C until the powder particles with a moisture content of 7-9% are ready for use.

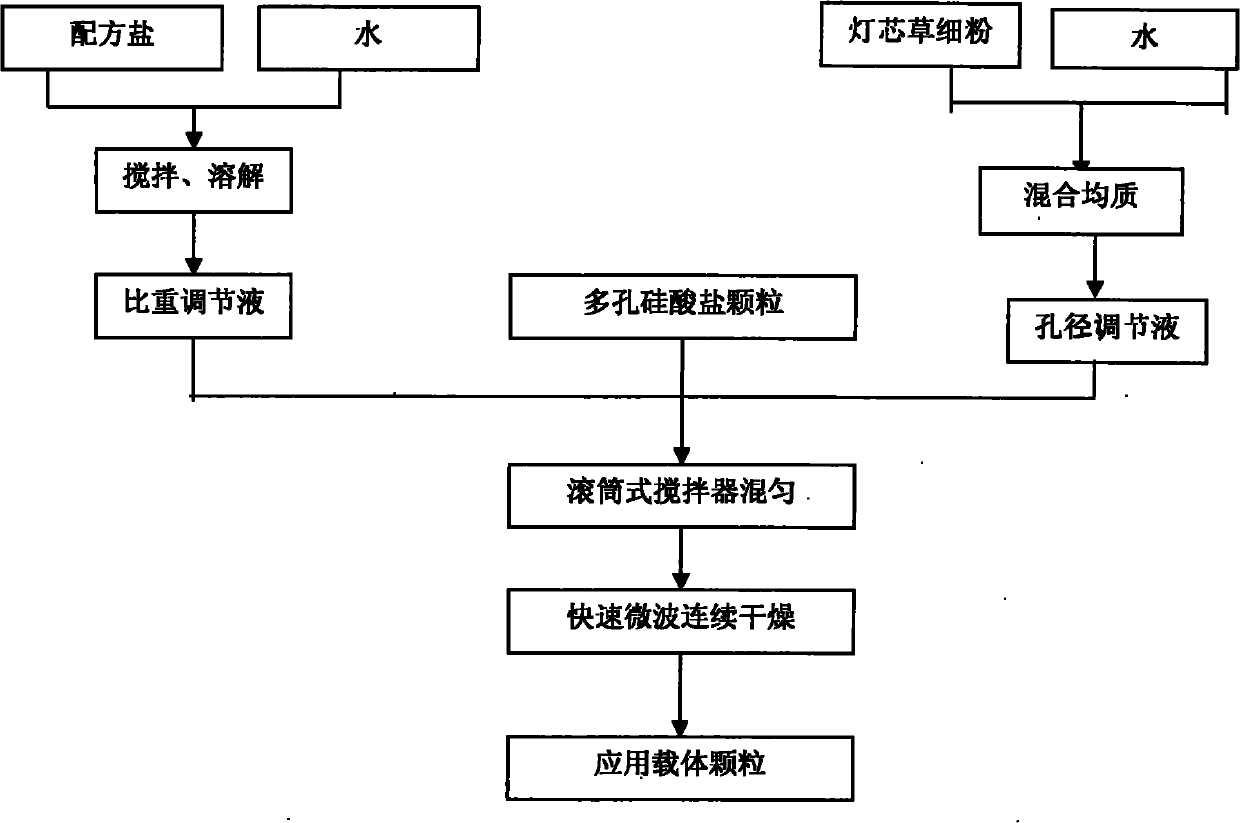

[0035] 2. Mix table salt and potassium citrate at a ratio of 1:2, and then make a specific gravity regulator with water at a solid-to-liquid ratio of 1:10 for later use; prepare 120-mesh puffed tobacco stem micropowder at a solid-to-liquid ratio of 1:10 aft...

Embodiment 2

[0047] Preparation of vanilla-flavored heat-sensitive plant fragrance uniform sustained-release granules for medicine

[0048] 1. The fermented vanilla beans are made into slurry in a refiner at a solid-to-liquid ratio of 1:5 (mass ratio, the same below), and filtered with a 150-mesh filter cloth. The filtrate was broken using an ultrasonic cell breaker. Ultrasonic frequency: 20KHZ, power: 1200W, processing time: 3min. Pre-freeze the slurry after the wall breaking treatment to -38°C, and then send it to a hot plate vacuum freeze dryer and freeze-dry it at a temperature of -6°C until the powder particles with a moisture content of 7-9% are ready for use.

[0049] 2. Mix potassium malate and potassium citrate at a ratio of 1:1, and then make a specific gravity regulator with water at a solid-to-liquid ratio of 1:12; mix 120 mesh rush micropowder with a solid-to-liquid ratio of 1:8 to make granules The pore size regulator is used for standby; the porous silicate granular materi...

Embodiment 3

[0061] Preparation of uniform sustained-release granules with complex fruity aroma and heat-sensitive plant aroma for convenience food

[0062] 1. Fresh apple pulp and banana pulp are respectively made into slurry in a refiner according to a solid-to-liquid ratio of 1:8 (mass ratio, the same below), and are filtered with a 150-mesh filter cloth; Wall breaking treatment, ultrasonic frequency: 20KHZ, power: 1200W, treatment time: 3min. Pre-freeze the slurry after wall breaking to -38°C, then send it to a hot plate vacuum freeze dryer and freeze-dry at -8°C until the powder particles with a moisture content of 7-9% are ready for use;

[0063] 2. Mix table salt, potassium malate and sodium citrate at a ratio of 1:1:1, and then make a specific gravity regulator with water at a solid-to-liquid ratio of 1:8; prepare 120 mesh cornstalk porous fiber micropowder at a solid-to-liquid ratio of 1: After the 8 substances are stirred, it is prepared as a particle pore size regulator for use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com