Mixing device for glass bottle making

A mixing device and glass bottle technology, applied in glass production and other directions, can solve the problems of poor melting process, low glass strength, long production cycle, etc., and achieve the effects of rapid melting, high glass strength and reduced labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

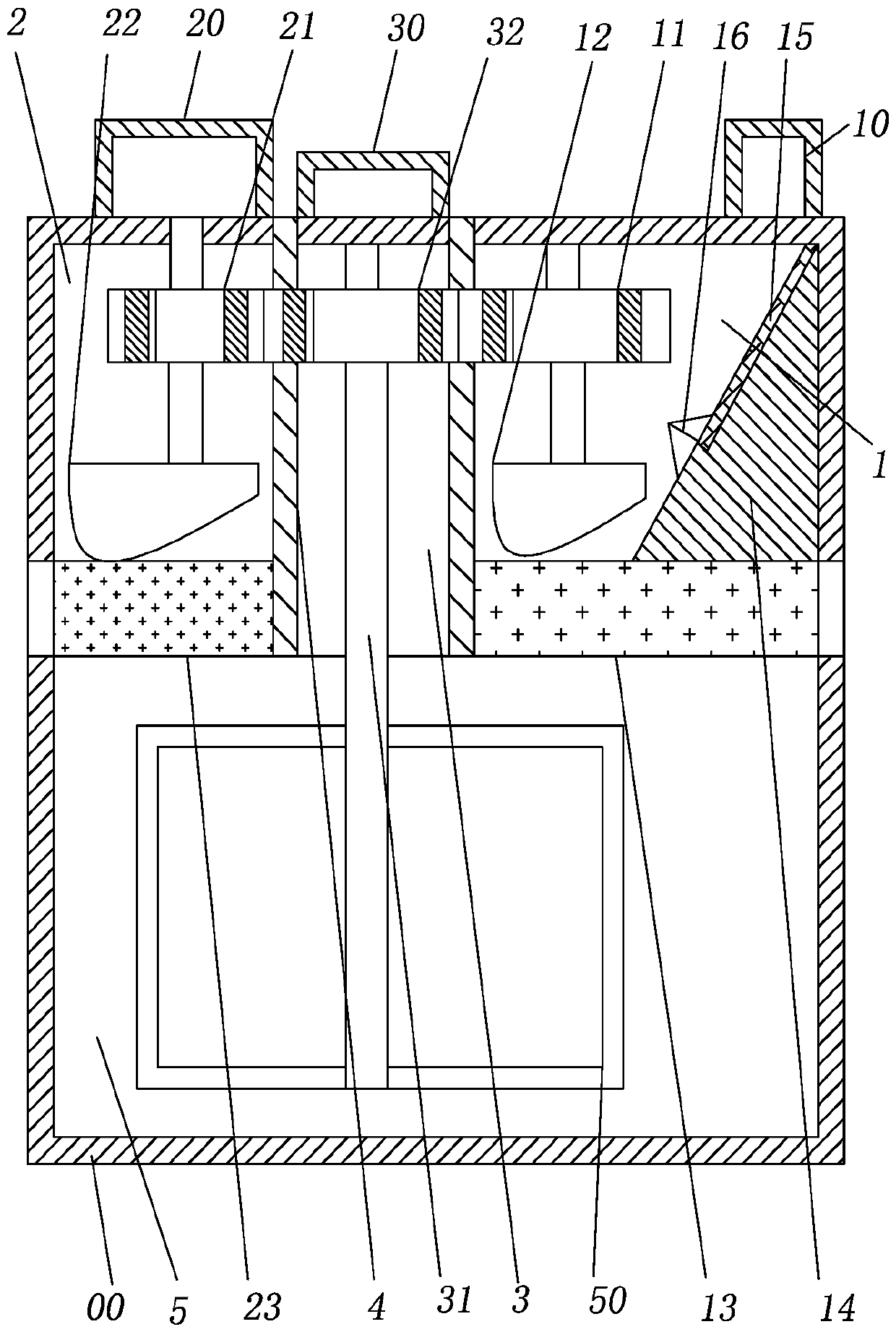

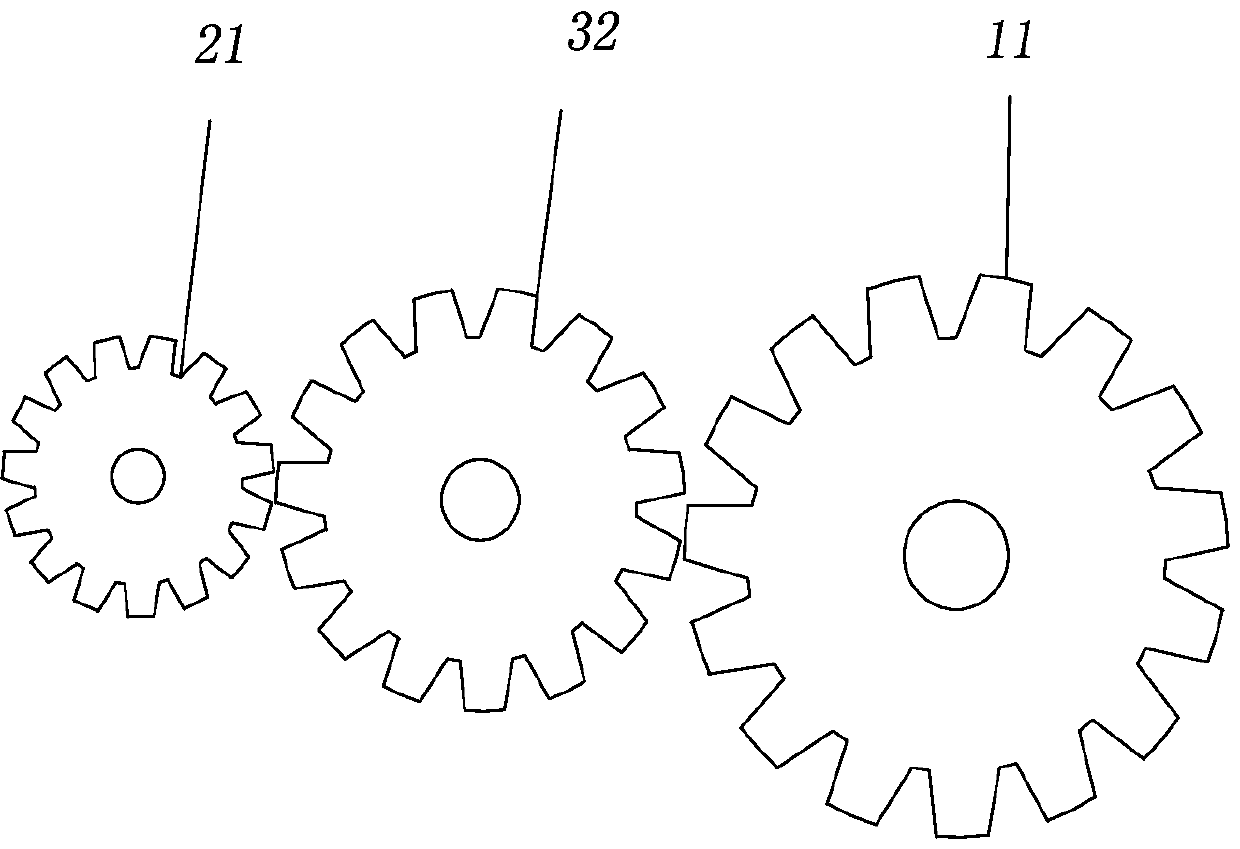

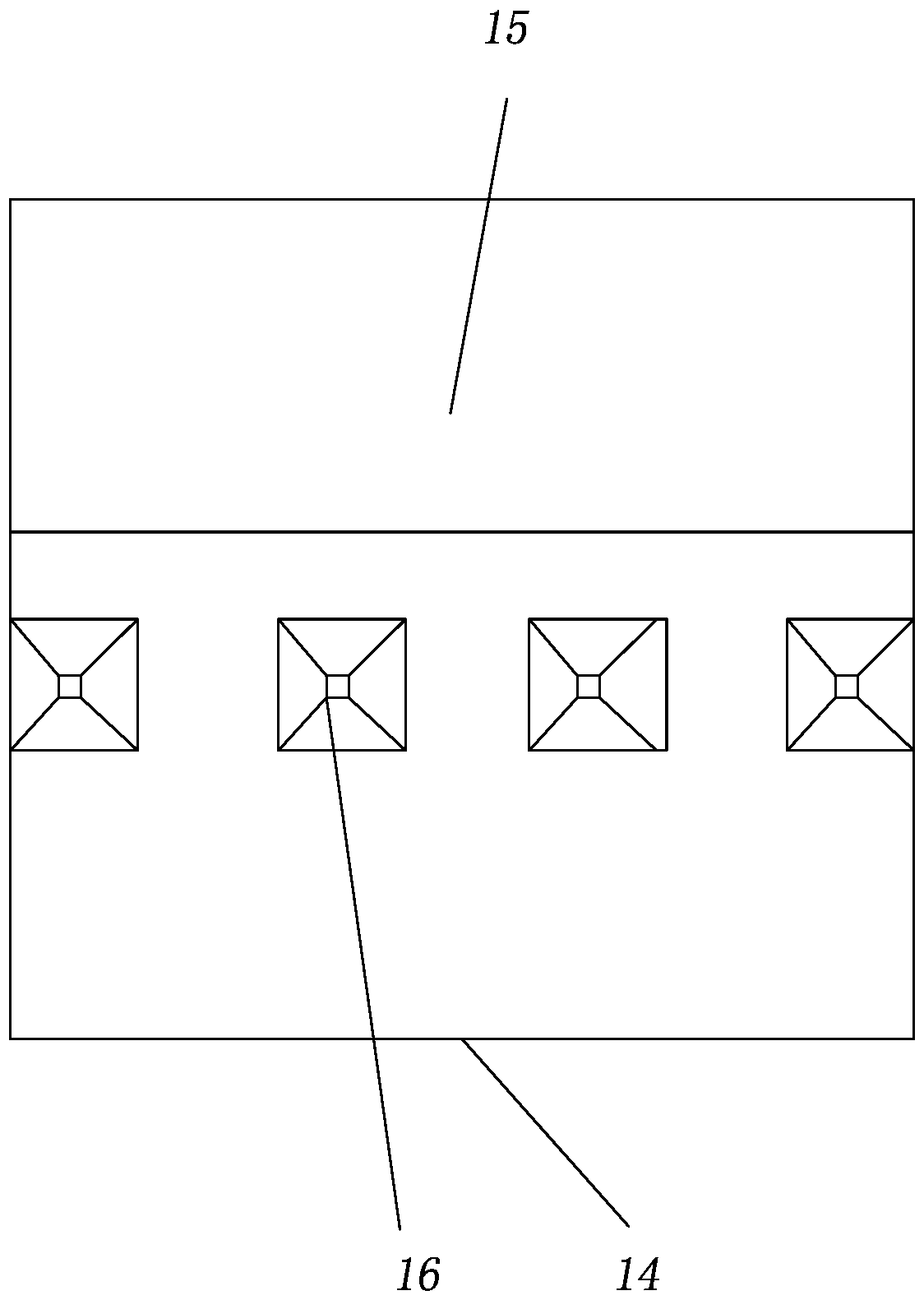

[0023] The reference signs in the drawings of the description include: box body 00, coarse crushing chamber 1, coarse material port 10, third gear 11, coarse crushing wheel 12, coarse screen 13, inclined plate 14, magnet 15, crushing knife 16, Fine crushing chamber 2, fine material port 20, first gear 21, fine crushing wheel 22, fine screen 23, feeding chamber 3, feeding port 30, stirring shaft 31, second gear 32, partition 4, mixing chamber 5, stirring Leaves 50.

[0024] The embodiment is basically as attached figure 1 Shown: a mixing device for making glass bottles, including a motor and a box 00. The box 00 is equipped with a coarse crushing chamber 1, a fine crushing chamber 2, a feeding chamber 3 and a mixing chamber 5; a coarse crushing chamber 1 and a fine crushing chamber 2 1. The feeding chamber 3 is separated by two partitions 4, and the two partitions 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com