Low-reflection high-resolution glass

A high-resolution, low-reflection technology, applied in the field of glass, can solve the problems of reduced mirror reflectivity, poor film firmness, and large surrounding environmental pollution, etc., to achieve the effect of reducing mirror reflection and increasing light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

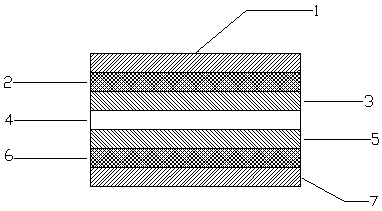

[0020] Such as figure 1 As mentioned above, the present invention provides a low-reflection high-resolution glass, which includes an upper protective layer 1 from top to bottom, an upper anti-reflection and anti-reflection layer 2, an upper anti-glare layer 3, a glass substrate 4, a lower anti-glare layer 5, The antireflection and anti-reflection layer 6 and the lower protective layer 7 are lowered. The upper and lower protective layers have a thickness of 1 nm, the upper and lower anti-reflection and anti-reflection layers have a thickness of 10 nm, and the upper and lower anti-glare layers have a thickness of 100 nm.

[0021] Wherein the protective layers 1 and 7 are zirconia layers, the zirconia layers are amorphous and the stoichiometric ratio of zirconia to zirconia is 1:2. The anti-reflection and anti-reflection layers 2 and 6 are composite layers of silicon and silicon oxide, and the thickness ratio of the silicon and silicon oxide layers is 1:1. The antiglare layers ...

Embodiment 2

[0026] Such as figure 1 As mentioned above, the present invention provides a low-reflection high-resolution glass, which includes an upper protective layer 1 from top to bottom, an upper anti-reflection and anti-reflection layer 2, an upper anti-glare layer 3, a glass substrate 4, a lower anti-glare layer 5, The antireflection and anti-reflection layer 6 and the lower protective layer 7 are lowered. The thickness of the upper and lower protective layers is 5nm, the thickness of the upper and lower antireflection and anti-reflection layers is 40nm, and the thickness of the upper and lower antiglare layers is 160nm.

[0027] Wherein the protective layers 1 and 7 are zirconia layers, the zirconia layers are amorphous and the stoichiometric ratio of zirconia to zirconia is 1:2. The anti-reflection and anti-reflection layers 2 and 6 are composite layers of silicon and silicon oxide, and the thickness ratio of the silicon and silicon oxide layers is 1:5. The antiglare layers 3 and...

Embodiment 3

[0032] Such as figure 1 As mentioned above, the present invention provides a low-reflection high-resolution glass, which includes an upper protective layer 1 from top to bottom, an upper anti-reflection and anti-reflection layer 2, an upper anti-glare layer 3, a glass substrate 4, a lower anti-glare layer 5, The antireflection and anti-reflection layer 6 and the lower protective layer 7 are lowered. The thickness of the upper and lower protective layers is 10nm, the thickness of the upper and lower antireflection and anti-reflection layers is 100nm, and the thickness of the upper and lower antiglare layers is 200nm. Wherein the protective layers 1 and 7 are zirconia layers, the zirconia layers are amorphous and the stoichiometric ratio of zirconia to zirconia is 1:2.

[0033] The anti-reflection and anti-reflection layers 2 and 6 are composite layers of silicon and silicon oxide, and the thickness ratio of the silicon and silicon oxide layers is 1:10. The antiglare layers 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com