Device and method for preparing high-quality pyrolysis gas and activated carbon by self-cleaning gasifying-pyrolyzing coupling and activating through organic matters

A self-cleaning, pyrolysis gas technology, applied in the direction of climate sustainability, chemical industry, manufacture of combustible gas, etc., can solve the problems of low economic added value, environmental pollution, low quality activated carbon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

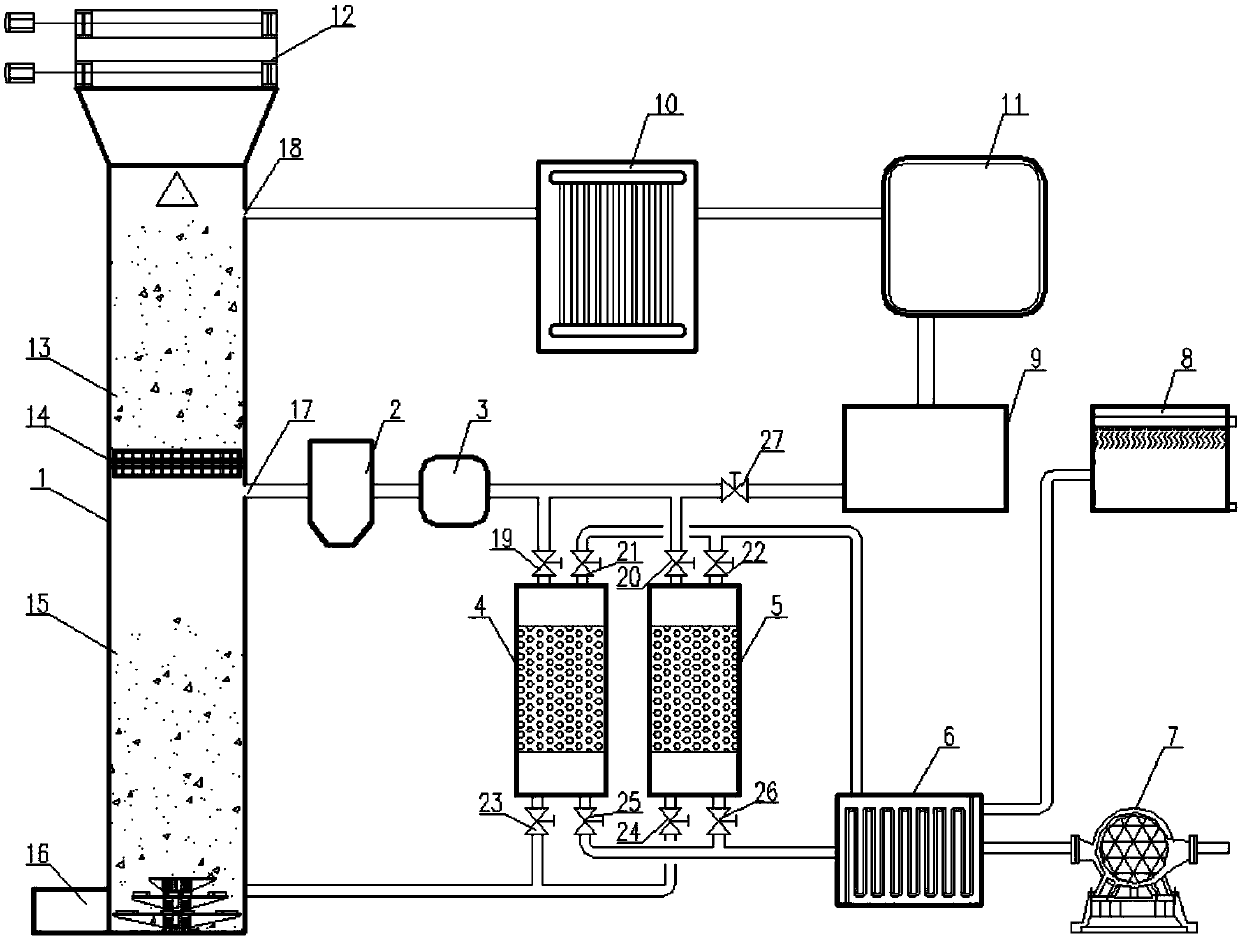

[0030] Such as figure 1As shown, the organic matter is sent to the dry pyrolysis zone 13 through the double-enclosed feed zone 12 of the self-cleaning gasification-pyrolysis coupling activation device 1, and the pyrolysis reaction occurs in the lower part of the dry pyrolysis zone to produce pyrolysis gas, tar and semi Coke and semi-coke fall into the gasification activation zone 15 through the pressure partition 14, and the tar is reformed many times and cracked into small molecule pyrolysis gas. The upper pyrolysis gas is sent to the low-temperature condensation device 10 through the upper pyrolysis gas outlet 18 for condensation , the pyrolysis gas whose temperature is lower than 30°C is sent to the gas cabinet 11 for storage; part of the semi-coke falling into the gasification activation zone 15 undergoes gasification reaction to generate gasification gas, and part of the gasification gas is sent to the dry pyrolysis zone 13 To provide energy for the dry pyrolysis of organ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com