Preparation method for multifunctional purifying solution

A purification liquid and multi-functional technology, applied in the field of preparation of multi-functional purification liquid, can solve the problems of poor corrosion resistance, inability to achieve rust prevention, incompleteness, etc., and achieve the effect of reducing deposition and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

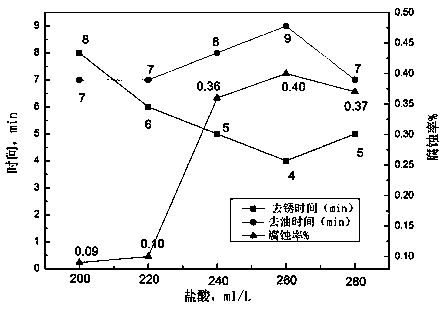

Image

Examples

specific Embodiment approach 1

[0028] Specific embodiment one: the preparation method of a kind of multifunctional purification liquid of the present embodiment is carried out according to the following steps:

[0029] 1. Preparation of hydrochloric acid

[0030] Prepare the hydrochloric acid of 200 ml / L, stand-by;

[0031] 2. Preparation of Phosphoric Acid

[0032] Prepare the phosphoric acid of 40 g / L, stand-by;

[0033] 3. Preparation of Surfactant OP-10

[0034] The tensio-active agent OP-10 of preparation 20 g / L, stand-by;

[0035] 4. Preparation of EDTA

[0036] Prepare 8 g / L of EDTA for use;

[0037] 5. Preparation of multifunctional purification solution

[0038] Mix the solutions from step 1 to step 4 sequentially to obtain a multifunctional purification solution.

[0039] In the multifunctional purification solution of the present invention, hydrochloric acid is the main derusting substance, phosphoric acid is an auxiliary derusting substance that has an acceleration effect on derusting, an...

specific Embodiment approach 2

[0041] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the concentration of hydrochloric acid described in step 1 is 200 ml / L, which is used as the main substance for pickling. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0042] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the phosphoric acid concentration in step 2 is 40 g / L, which can accelerate pickling and prevent corrosion for a short time. Others are the same as in the first or second embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap