Composite lining structure for permafrost tunnel and construction technology

A construction technique and composite technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of increasing operation management difficulty and maintenance cost, cracking of tunnel lining structure, economic loss, etc., to avoid engineering quality problems, simple machinery, The effect of guaranteeing the progress of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

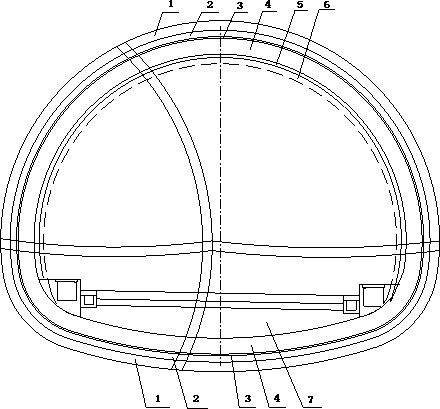

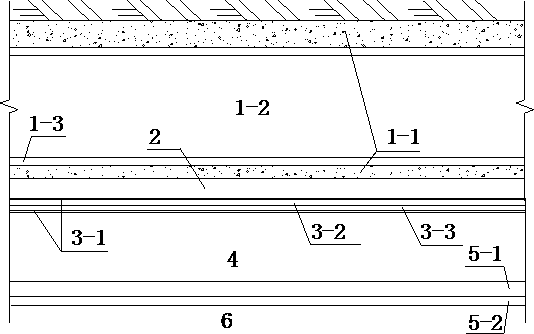

[0032] Composite lining structure: the support structure 1 is followed by the primary lining structure 2, the waterproof and thermal insulation layer 3, the secondary lining structure 4 and the thermal insulation and fireproof layer 5.

[0033] The waterproof insulation layer 3 is composed of a four-layer structure of non-woven geotextile 3-1, waterproof board 3-2, polyurethane heat insulation board 3-3 and non-woven geotextile 3-1.

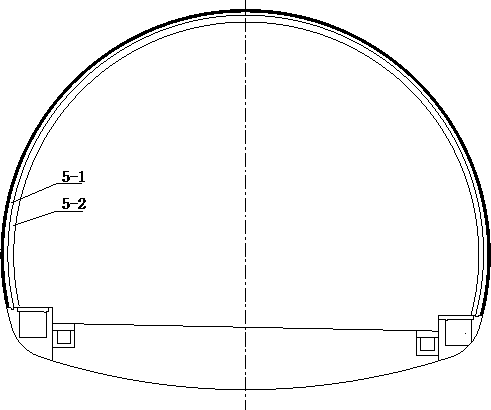

[0034] The thermal insulation and fire protection layer 5 is connected to the secondary lining structure 4 through expansion bolts 5-7, one end of the expansion bolt 5-7 is installed in the secondary lining structure 4, and the other end is connected to the U-shaped connector 5-3, and the U-shaped connector 5-3 Fixed on both sides of the keel 5-4, the fiber reinforced board 5-2 is fixed on the keel 5-4, and the cavity formed between the fiber reinforced board 5-2 and the secondary lining structure 4 is filled with the thermal insulation board 5-1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com