Continuous fiber prepreg tape winding pipe with hollow walls

A continuous fiber and winding tube technology, which is applied in the field of hollow wall continuous fiber prepreg tape winding tube, can solve the problems of layered and delaminated separation of the outer wound metal tape, poor long-term use effect, and short service life, so as to reduce engineering costs. Comprehensive cost, good integration, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

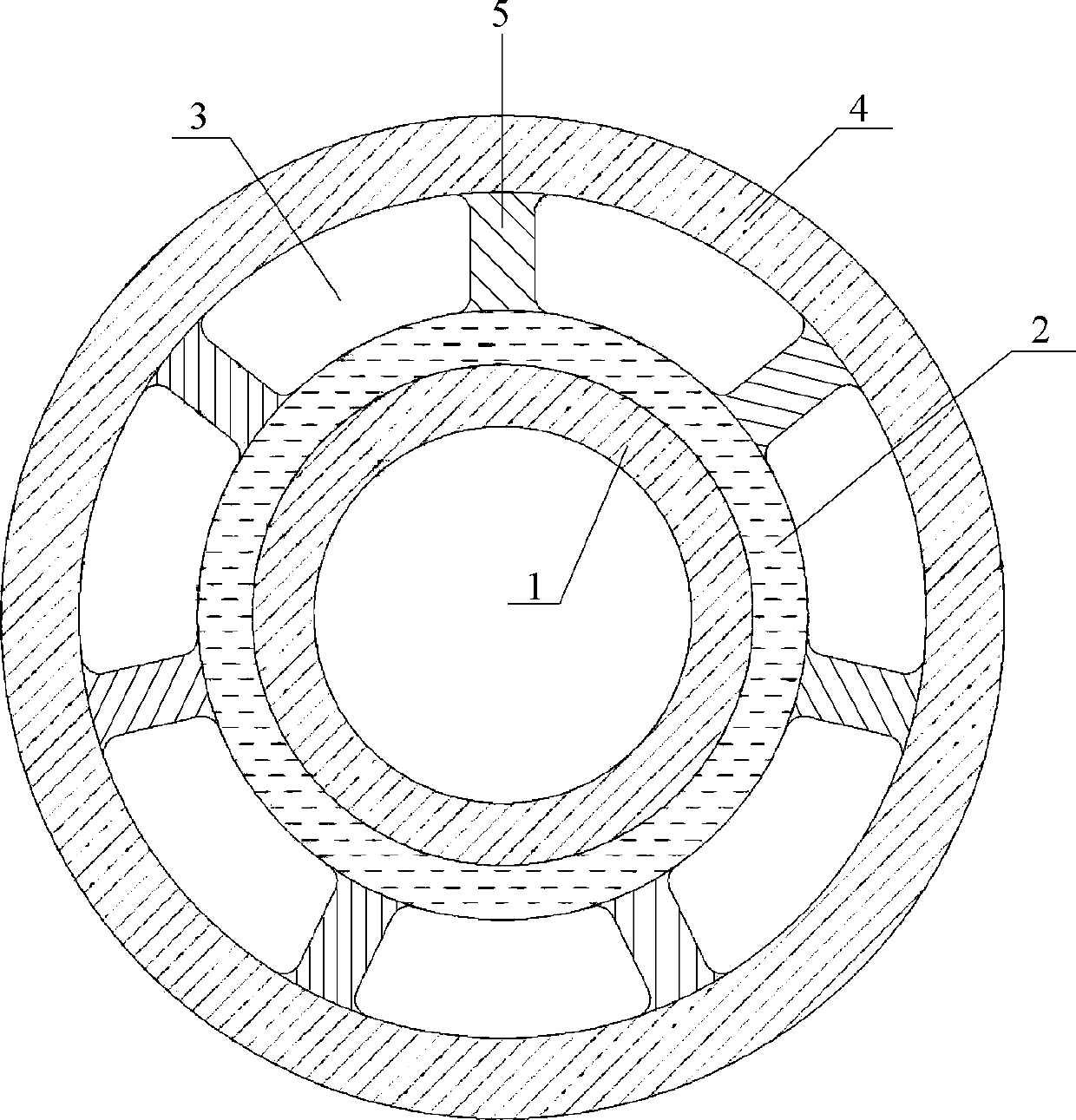

[0022] A hollow-walled continuous fiber prepreg tape winding pipe, including a tubular pipe body 1, a continuous fiber reinforced bearing layer 2, a protective surface layer 4 and support ribs 5, such as figure 1 As shown, the specific structure is:

[0023] The pipe body 1 serves as the inner stress conduction layer;

[0024] The continuous fiber reinforced bearing layer 2 is pasted on the outer wall of the pipe body 1, and the protective surface layer 4 is sleeved outside the continuous fiber reinforced bearing layer 2, and a hollow space is formed between the continuous fiber reinforced bearing layer 2 and the protective surface layer 4. The wall layer 3, the outer wall of the continuous fiber reinforced bearing layer 2 and the inner wall of the protective surface layer 4 are connected by seven supporting ribs 5, and the supporting ribs 5 are evenly distributed around the continuous fiber reinforced bearing layer 2.

[0025] In this embodiment: the pipe body 1 and the cont...

Embodiment 2

[0028] A hollow-walled continuous fiber prepreg tape winding pipe, including a tubular pipe body 1, a continuous fiber reinforced bearing layer 2, a protective surface layer 4 and support ribs 5, such as figure 1 As shown, the specific structure is: the hollow wall layer 3 is evacuated, and the two ends of the mesoporous wall layer 3 are closed with heat-insulating materials. Other structures are all the same as in Embodiment 1.

[0029] When the present embodiment is used, after the hollow wall layer 3 is evacuated and sealed with insulating materials at both ends, it can become a vacuum insulation pipe, which greatly reduces the thermal conductivity of the pipe. Other usage methods are all the same as embodiment 1.

Embodiment 3

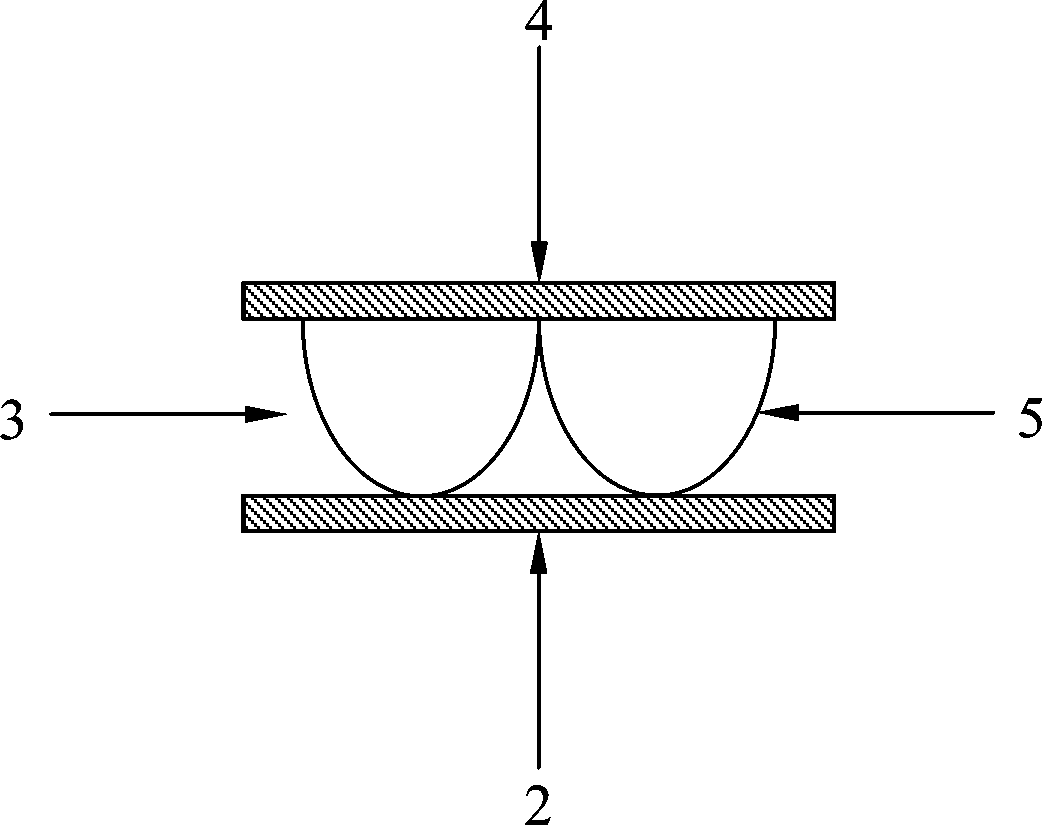

[0031] A hollow-walled continuous fiber prepreg tape winding pipe, including a tubular pipe body 1, a continuous fiber reinforced bearing layer 2, a protective surface layer 4 and support ribs 5, such as figure 2 As shown, the specific structure is: the supporting rib 5 is W-shaped. Other structures are all the same as Embodiment 2.

[0032] When the present embodiment is used, after the hollow wall layer 3 is evacuated and sealed with insulating materials at both ends, it can become a vacuum insulation pipe, which greatly reduces the thermal conductivity of the pipe. Other usage methods are all the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com