Vertical tool auxiliary device for aircraft panel assembling

A technology of aircraft wall panels and auxiliary devices, which is applied in the field of aircraft panel assembly vertical tooling auxiliary devices, can solve the problems of aircraft panel deformation, reduce the quality of aircraft panel assembly, and affect the accuracy of drilling and riveting, so as to improve the assembly quality, The effect of improving the precision of drilling and riveting and reducing the amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

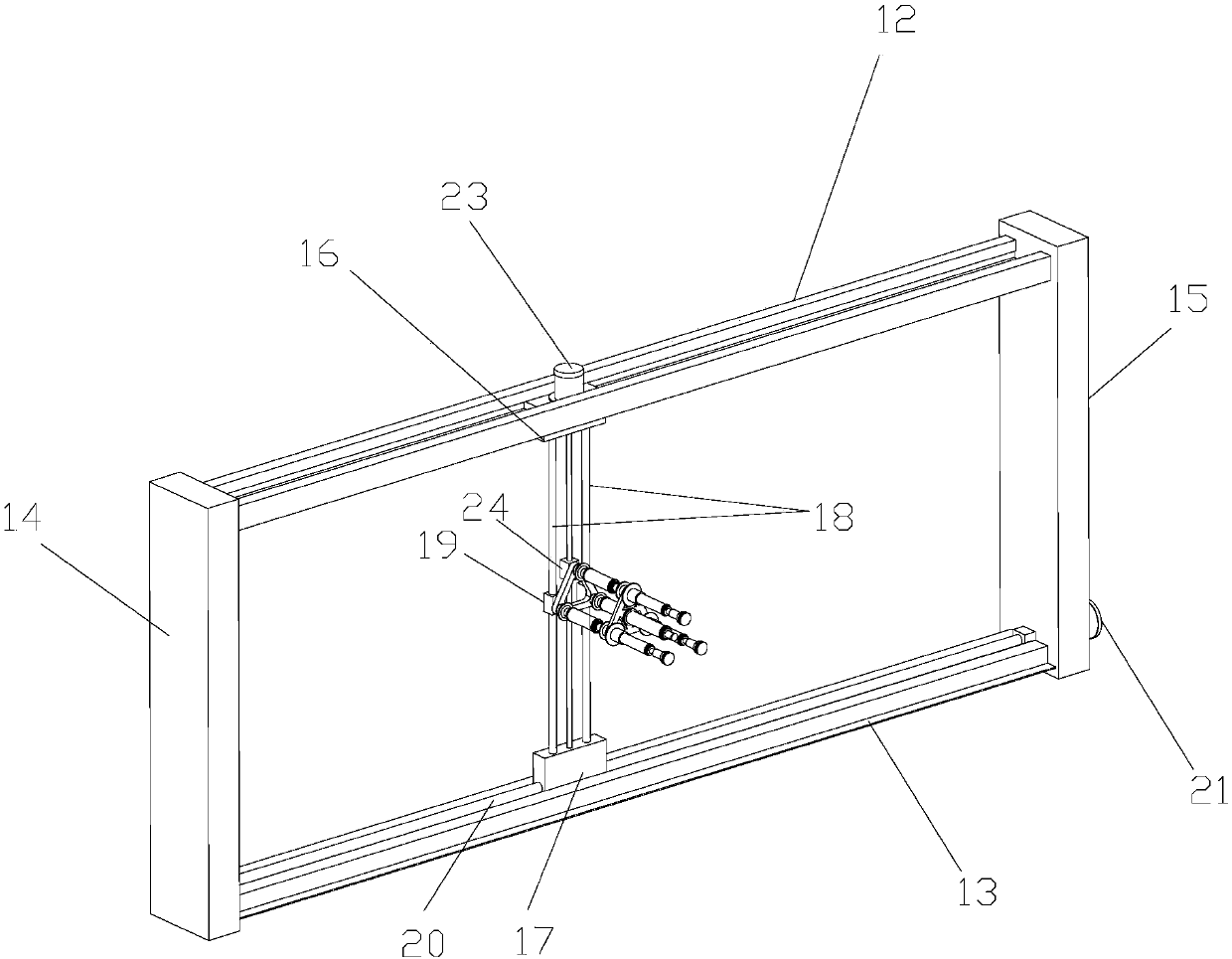

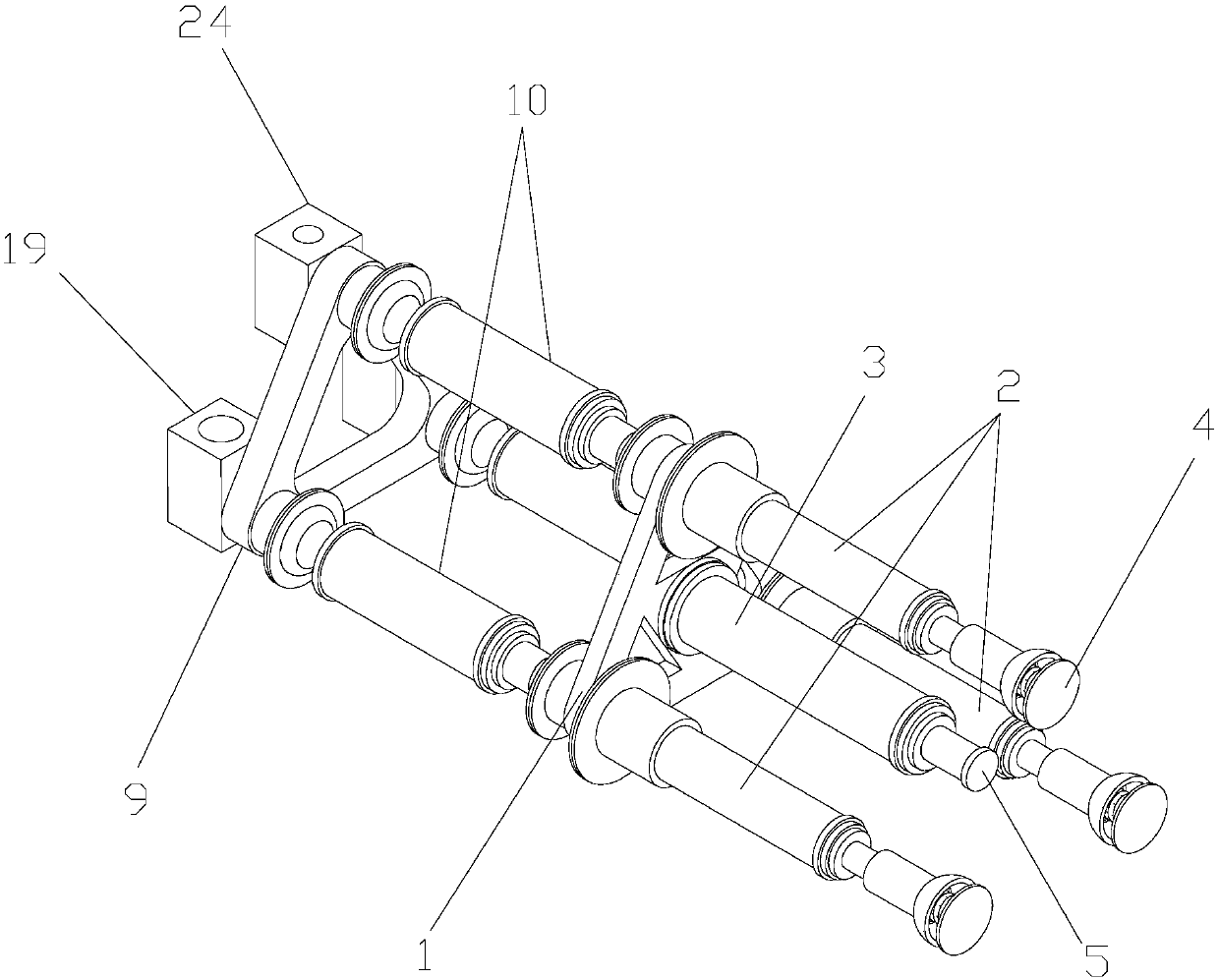

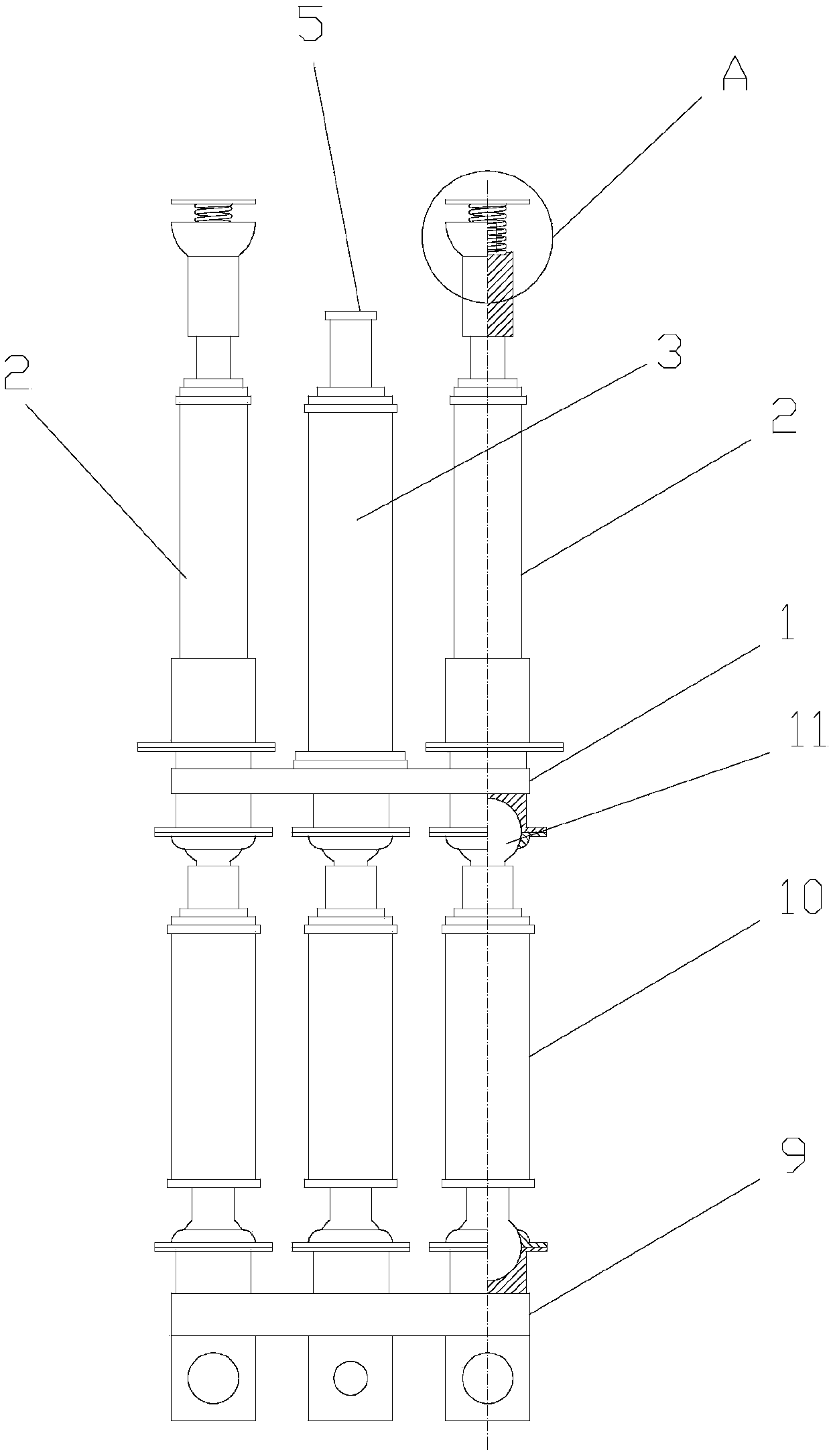

[0025] Such as Figure 1 to Figure 7 As shown: the vertical tooling auxiliary device for aircraft panel assembly in this embodiment includes a frame and an actuator movable on the frame; the actuator includes a base plate I1 and a clamping cylinder 2 arranged side by side on the base plate I1 And the pressure riveting cylinder 3, the piston rod end of the said jacking cylinder 2 is provided with a jacking end block 4 for pressing against the aircraft wall plate, and the piston rod end of the said pressure riveting cylinder 3 is provided with a pier for rivets. Pressed riveting end block 5; the actuator is movable on the frame, that is, the actuator can move freely within a certain range on the frame to adjust the position coordinates and normal posture according to the processing needs of the aircraft panel; The device is used in conjunction with the drilling and riveting mechanism, and the frame can be fixed on the tooling machine tool. The pressing cylinder 2 and the presser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com