Form-stable composite material with a layer of fiber-reinforced recycled ground material

A composite material and material layer technology, applied in the field of composite materials, can solve problems such as high price, poor sound absorption ability, and reduced sound emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

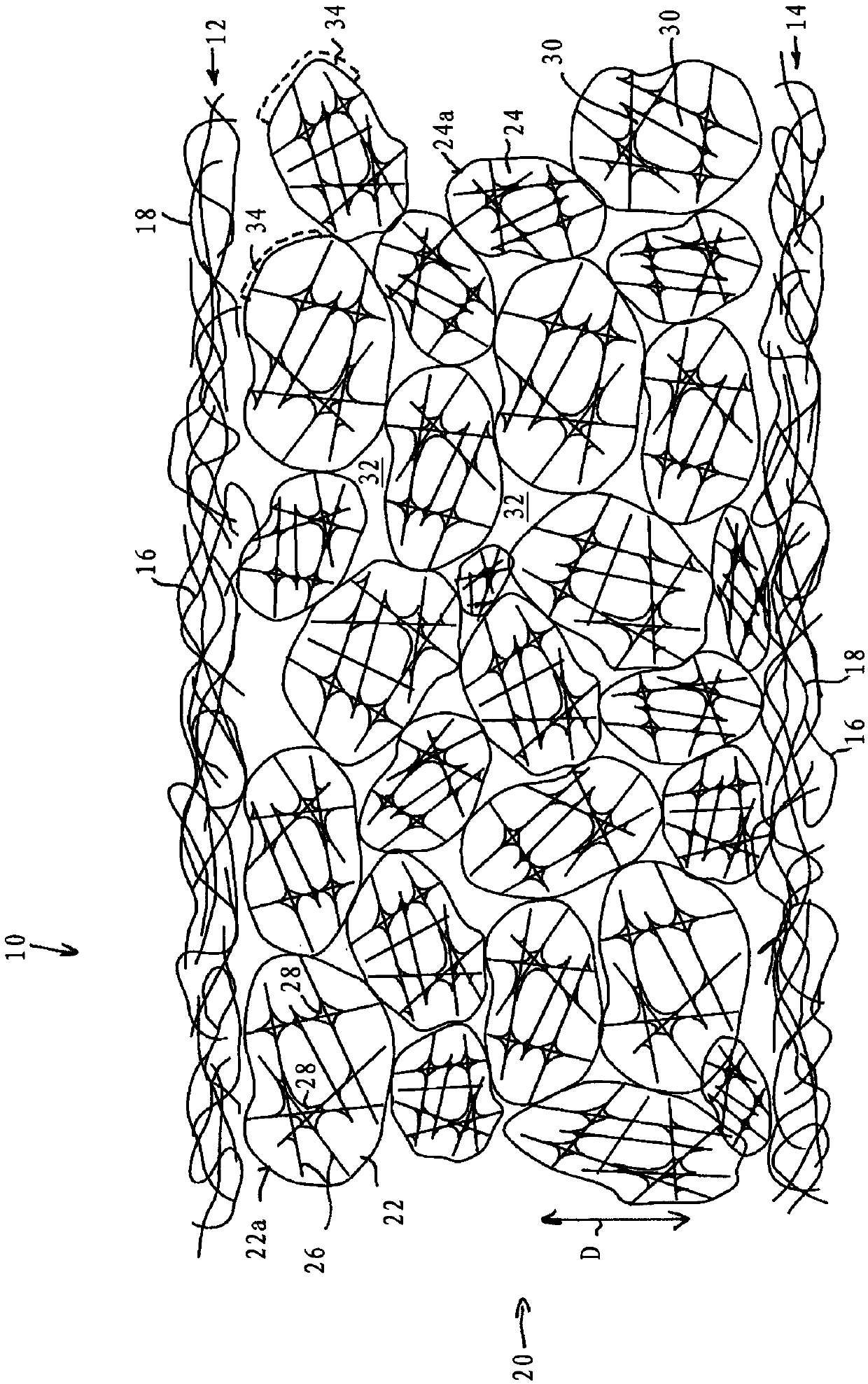

[0041] exist figure 1 Shown in is a cross-sectional view of an embodiment of the shape-stable composite material of the present invention, generally designated 10 . The composite material 10 comprises a first and a second flexible layer 12 or 14, which are respectively produced as nonwoven layers in the example shown. The non-woven layers 12 and 14 can each have different fibers, for example thermoplastic bonding fibers 16 made of polyolefins, in particular polypropylene, and thermoplastic bonding fibers 16 made of heat-shrinkable bonding fibers 16. Reinforcing fibers 18 of a dimensionally stable material in the case of temperature. For example, the reinforcing fibers 18 may consist of polyethylene terephthalate.

[0042] As a supplement or alternative to the nonwoven layers 12 and 14, the flexible layers 12 and 14 can have other or additional layers, for example a solid plastic film or / and a metal foil, in particular a Microporous aluminum foil.

[0043] Between the flexi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com