Method for purifying diamond micro-powder

A technology of diamond micropowder and purification method, applied in the field of diamond micropowder purification, can solve the problems such as the impurity of diamond micropowder cannot be effectively removed and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

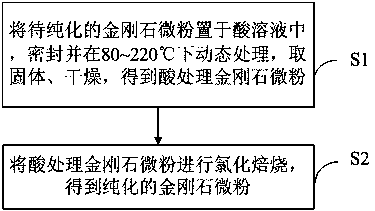

Method used

Image

Examples

Embodiment 1

[0039] Weigh 1000g of diamond micropowder raw material to be purified and put it into a 6L reaction kettle, add the prepared mixed acid solution (the concentration of hydrochloric acid is 1.5mol / L, the concentration of nitric acid is 0.5mol / L, and the concentration of hydrofluoric acid is 3.0mol / L) 2.5L, put the lid on and seal it and put it on the external heating inverting rack, set the temperature at 180°C, invert frequency at 10 revolutions / min clockwise, and finish the reaction in 24 hours.

[0040]After the high-temperature dynamic acid leaching treatment is completed, the upper part of the acid solution is poured out after the diamond powder has settled to prevent acid-insoluble plastic particles from floating on the acid surface. Add a sufficient amount of deionized water to dilute, pour the diamond micropowder together with the diluted acid solution into the pressure filter tank, seal the tank mouth, open the vent valve, and let in high-purity nitrogen to discharge the...

Embodiment 2

[0042] Weigh 1000g of diamond micropowder raw material to be purified and add it into the quartz tube for high temperature chlorination, connect the ventilation and gas outlet pipes, raise the temperature to 600°C, feed high-purity hydrogen chloride gas at a rate of 5L / min, and absorb the tail gas with sodium hydroxide solution , and then continue to heat up to 1000 ° C, start timing, after 2 hours of chlorination reaction, turn off the heating power, stop feeding hydrogen chloride gas, switch to feeding high-purity nitrogen for 5 minutes, remove residual hydrogen chloride gas in the diamond powder, wait After cooling, the diamond micropowder is taken out to obtain purified diamond micropowder B.

Embodiment 3

[0044] Weigh 1000g of diamond powder A and add it into the quartz tube for high-temperature chlorination, connect the ventilation and outlet pipes, raise the temperature to 600°C, and feed high-purity hydrogen chloride gas at a rate of 5L / min. The tail gas is absorbed by sodium hydroxide solution, and then continue Raise the temperature to 1000°C and start timing. After 2 hours of chlorination reaction, turn off the heating power supply, stop feeding hydrogen chloride gas, switch to feeding high-purity nitrogen gas for 5 minutes to remove residual hydrogen chloride gas in the diamond powder, and put The diamond micropowder is taken out to obtain purified diamond micropowder C.

[0045] The diamond micropowder A after the purification, the diamond micropowder B after the purification, the diamond micropowder C after the purification and the diamond micropowder raw material are carried out element analysis, and the result is as shown in table 1:

[0046] Table 1

[0047] Unit: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com