Device for producing diesel oil by using waste diesel oil

A technology of waste engine oil and diesel oil, which is applied in the direction of only multi-stage series refining and cracking process treatment, lubricating composition, etc., can solve the problems that impurities cannot be effectively removed, and the use effect is not good, so as to improve social and economic benefits, The design is reasonable and practical to achieve the effect of recycling resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

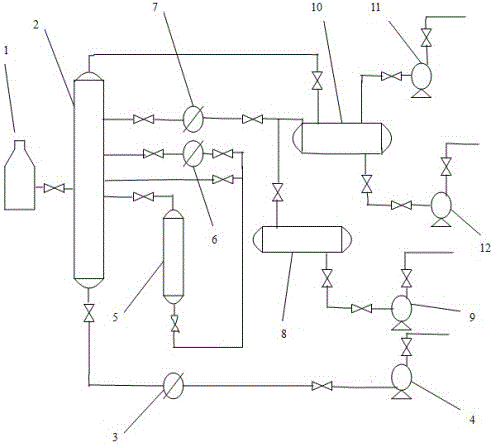

[0007] As shown in the figure, a waste engine oil production diesel equipment mainly consists of a heating furnace 1, a vacuum tower 2, a first cooler 3, a first pump 4, a reactor 5, a second cooler 6, and a third cooler 7 , a diesel tank 8, a second pump 9, a gas-liquid separation tank 10, a fourth pump 11 and a third pump 12.

[0008] The technical process of the present invention: after the waste engine oil is pre-treated, it is distilled in the decompression tower, and the fraction of diesel oil and lighter than diesel oil is drawn out from the side line of the tower into the diesel fraction tank, and the fraction heavier than diesel oil enters the tank equipped with cracking catalyst. The reactor is cracked at 350-390°C, and then returned to the tower for fractionation after cracking. Such circulation can obtain the maximum yield of diesel oil. The catalyst is silicon / aluminum, molecular sieve or type-selective molecular sieve catalyst, and the catalyst life is designed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com