Diamond abrasive and preparation method thereof

A diamond and diamond micropowder technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem that graphite and metal impurities cannot be effectively removed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

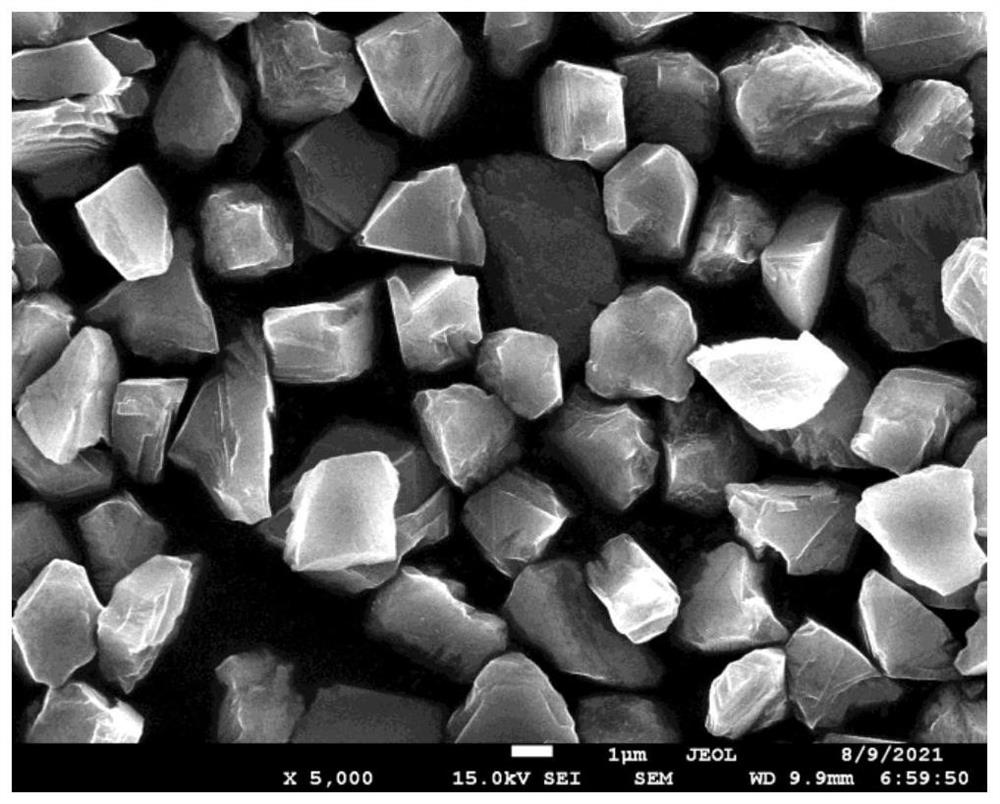

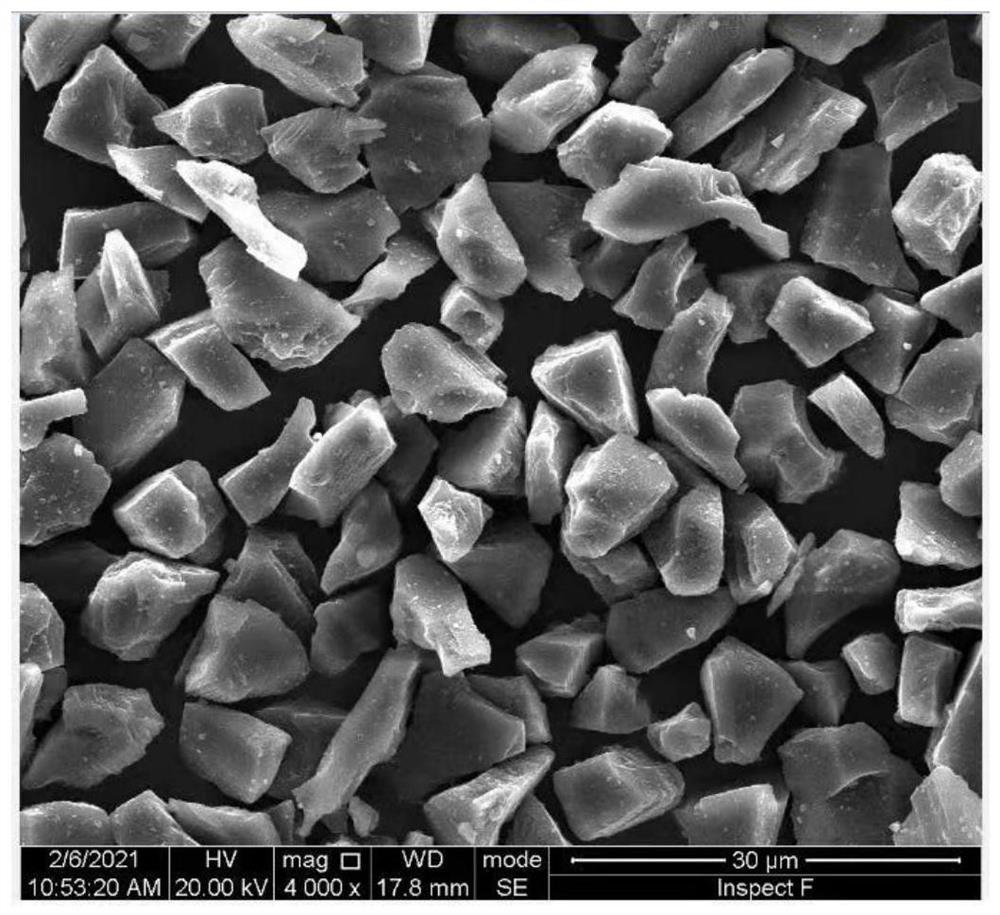

Image

Examples

Embodiment 1

[0036] The preparation method of the diamond abrasive of the present embodiment may further comprise the steps:

[0037] (1) Put 5000g of ball-milled diamond micropowder into the roasting furnace tray (the charging thickness of the diamond micropowder after shaping is 1.5cm), put the tray into the roasting furnace, and roast under the condition that the roasting temperature is 380°C 1h, after the roasting is finished, cool down to room temperature through the air blowing system of the roasting furnace.

[0038] (2) Add 6000mL sulfuric acid solution in the 10L glass reactor (the sulfuric acid solution is obtained by mixing concentrated sulfuric acid and water with a volume ratio of 1:1, and the mass fraction of concentrated sulfuric acid is 98%), 50g sodium chloride, 4000g roasted Diamond micropowder, then energized and heated, so that the system in the glass reactor is pickled under the condition of stirring and temperature at 180°C. The pickling time is 1h. After the pickling...

Embodiment 2

[0041] The preparation method of the diamond abrasive of the present embodiment may further comprise the steps:

[0042] (1) Put 5000g of ball-milled diamond micropowder into the roasting furnace tray (the charging thickness of the diamond micropowder after shaping is 1.5cm), put the tray into the roasting furnace, and roast under the condition that the roasting temperature is 420°C 2h, after the roasting is finished, cool down to room temperature through the air blowing system of the roasting furnace.

[0043] (2) Add 6000mL hydrochloric acid solution (hydrochloric acid solution is obtained by mixing concentrated hydrochloric acid and water with a volume ratio of 1:1, the mass fraction of concentrated hydrochloric acid is 38%), 4000g of calcined diamond micropowder, and then plastic Put the bucket in a water bath at 100°C and heat and stir for 1 hour to carry out pickling. After the pickling, stop stirring until the pickled diamond powder is completely precipitated, pour out ...

Embodiment 3

[0046] The preparation method of the diamond abrasive of the present embodiment may further comprise the steps:

[0047] (1) Put 5000g of ball-milled diamond micropowder into the roasting furnace tray (the charging thickness of the diamond micropowder after shaping is 1.5cm), put the tray into the roasting furnace, and roast under the condition of 400°C at the roasting temperature 2h, after the roasting is finished, cool down to room temperature through the air blowing system of the roasting furnace.

[0048] (2) Add 5000mL sulfuric acid solution (the sulfuric acid solution is obtained by mixing concentrated sulfuric acid and water with a volume ratio of 3:7 in a 10L plastic barrel, the mass fraction of concentrated sulfuric acid is 98%), 50g sodium chloride, diamond after 4000g roasting Then put the plastic bucket in a water bath at 100°C and heat and stir for 1 hour for pickling. After the pickling, stop stirring until the pickled diamond powder is completely precipitated. P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com