Elastic composite building exterior wall coating

A composite technology for building exterior walls, applied in the field of chemical coatings and coatings, can solve the problems of insufficient internal structure of the coating film, staining, and difficulty in cleaning, so as to improve the stain resistance, prolong the service life, and improve the compactness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

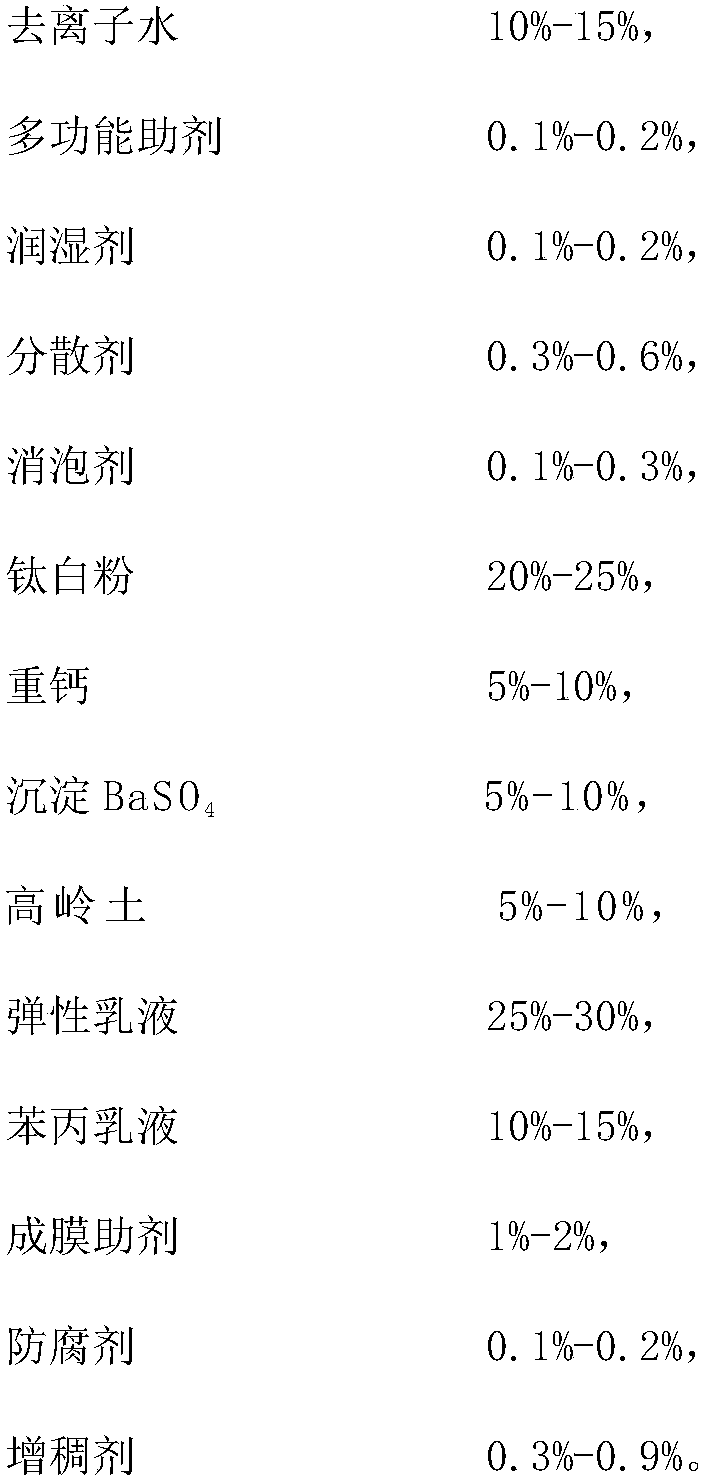

[0025] An elastic composite building exterior wall coating, comprising the following raw materials in percentage by weight: 10% deionized water, 0.1% 2-amino-2-methyl-1-propanol, 0.1% organically modified polysiloxane alcohol ether , 0.3% of alkylphenol polyoxyethylene ether, 0.1% of paraffin and hydrophobic silica, 25% of rutile titanium dioxide, 10% of ground calcium carbonate with a fineness of 1250 mesh, and precipitated BaSO with a fineness of 800 mesh 4 5%, water-washed calcined kaolin 8%, anionic elastic emulsion 25%, full acrylic resin emulsion 15%, dodecyl alcohol ester 1%, isothiazolinone 0.1%, polyether rheology modifier and alkali swelling Class thickener 0.3%.

[0026] The elastic composite building exterior wall paint produced according to the present invention has all the indicators that meet and exceed the requirements specified in JG / T172-2014 elastic architectural paint, has good elasticity, weather resistance, and water resistance, and can effectively cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com