Low-temperature 3D printing degradable green material for precision casting of a fired mold and preparation method of low-temperature 3D printing degradable green material

A 3D printing and precision casting technology, applied in the field of 3D printing materials, can solve the problems of easy generation of harmful gas, high temperature of wax removal, high energy consumption, etc., and achieve the effect of not easy to break wire, save energy, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

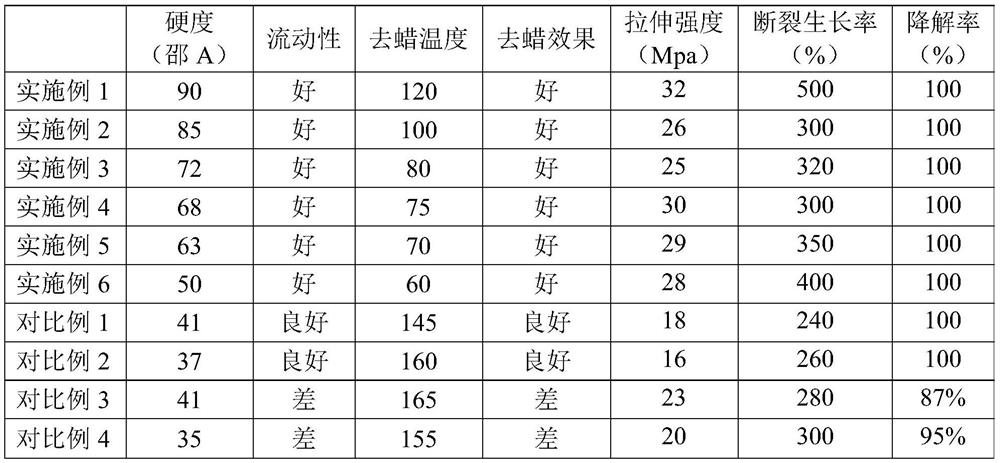

Embodiment 1

[0031] This example provides a low-temperature 3D printing degradable green material for investment casting investment, including the following raw materials in parts by mass: 100 parts of thermoplastic polyurethane, 10 parts of polycaprolactone (PCL), 5 parts of plasticizer and additives 0.5 parts; wherein, the melting temperature of thermoplastic polyurethane is 80-140°C, the molecular weight of polycaprolactone is 1000-60000, the auxiliary agent is zinc acetylacetonate, and the plasticizer is epoxy soybean oil.

[0032] The above-mentioned preparation method of low-temperature 3D printing degradable green materials for precision casting investment molds, the specific process is: dry the raw materials in a vacuum oven at 55 degrees for 24 hours; The time is 7 minutes; among them, the twin-screw temperature is set to 60°C in the feed section, 140°C in the compression section, 180°C in the metering section, and 150°C in the die head.

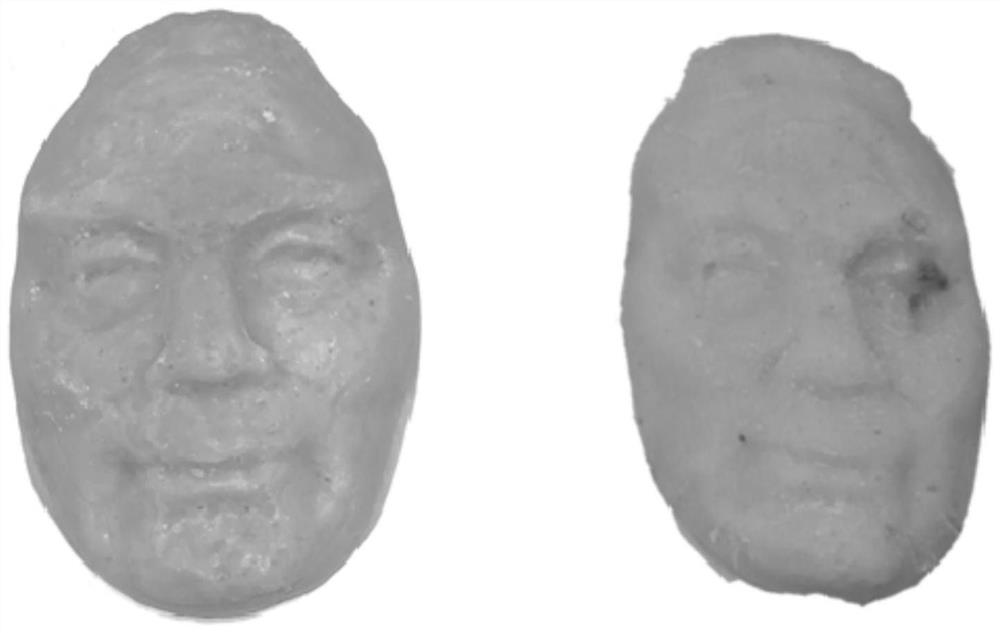

[0033] The 3D printed physical picture ma...

Embodiment 2

[0035] This example provides a low-temperature 3D printing degradable green material for investment casting investment, including the following raw materials in parts by mass: 100 parts of thermoplastic polyurethane, 40 parts of polycaprolactone (PCL), 15 parts of polyethylene glycol (PEG) 20 parts of plasticizer, 1 part of additive and 5 parts of filler; among them, the melting temperature of thermoplastic polyurethane is 80-140 ℃, the molecular weight of polycaprolactone is 1000-60000, and the molecular weight of polyethylene glycol is 800-4000 , the auxiliary agent is stannous octoate, the plasticizer is dioctyl phthalate, and the filler is diatomaceous earth.

[0036] The above-mentioned preparation method of low-temperature 3D printing degradable green materials for precision casting investment molds, the specific process is: dry the raw materials in a vacuum oven at 55 degrees for 24 hours; The time is 7 minutes; among them, the twin-screw temperature is set to 60°C in t...

Embodiment 3

[0038] This example provides a low-temperature 3D printing degradable green material for investment casting investment, including the following raw materials in parts by mass: 100 parts of thermoplastic polyurethane, 100 parts of polycaprolactone (PCL), 30 parts of polyethylene glycol (PEG) 40 parts, 40 parts of plasticizer, 2 parts of additives and 10 parts of filler; among them, the melting temperature of thermoplastic polyurethane is 80-140 ℃, the molecular weight of polycaprolactone is 1000-60000, and the molecular weight of polyethylene glycol is 800-4000 , the auxiliary agent is stannous octoate, the plasticizer is dioctyl phthalate, and the filler is diatomaceous earth.

[0039] The above-mentioned preparation method of low-temperature 3D printing degradable green materials for precision casting investment molds, the specific process is: dry the raw materials in a vacuum oven at 55 degrees for 24 hours; The time is 7 minutes; among them, the twin-screw temperature is se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com