Stationary disc

A technology of static disk and aluminum alloy material, which is applied to liquid fuel engines, mechanical equipment, pumps, etc., can solve the problems of short replacement cycle of static disk and unsustainable use, improve quality and compactness, reduce large pores and shrinkage. Pore shrinkage, the effect of promoting refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

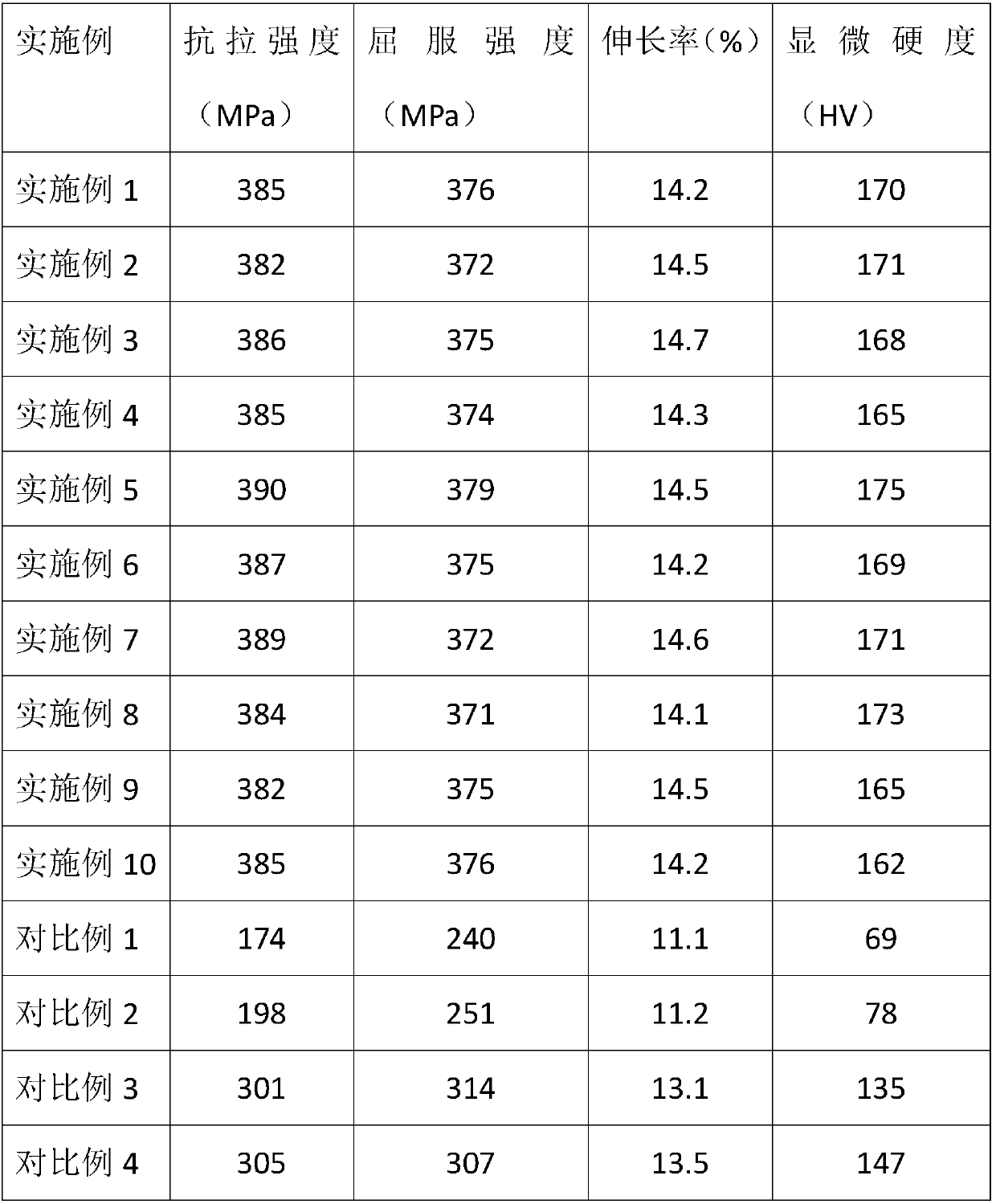

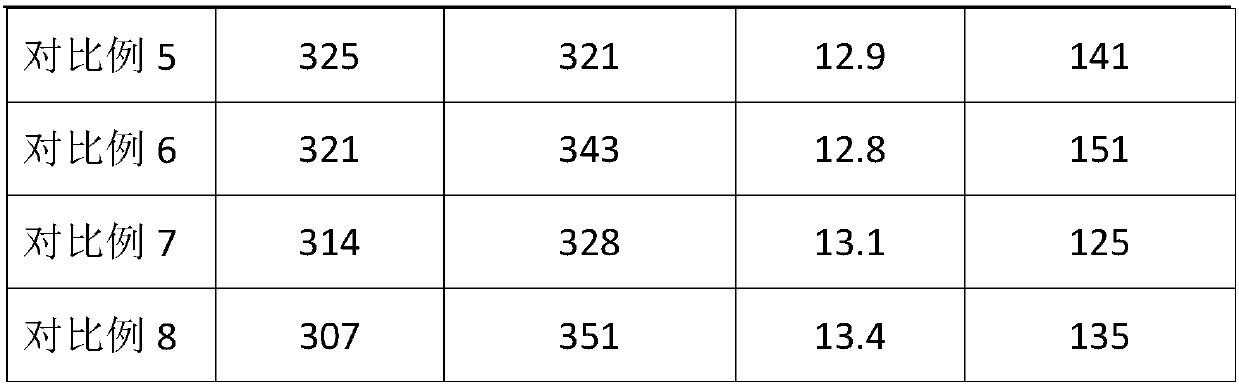

Examples

Embodiment 1

[0032] The aluminum alloy material composed of the following mass percentage components is smelted at 750°C, and 0.01% of the aluminum alloy mass detonator and 1.0% of the reinforcing agent are added during the smelting, and the iron rake is repeatedly stirred for 25 minutes to completely melt, and aluminum liquid is obtained; The composition and mass percentage of alloy materials: Si: 6%, Fe: 0.1%, Mg: 0.5%, Zr: 0.01%, Ti: 0.01%, B: 0.03%, La: 0.02%, the balance is aluminum Avoid impurities; then refining the molten aluminum with a refining temperature of 780°C. After refining, it is cooled to 690°C, while the mold is preheated to 150°C, and the cooling liquid is poured into the mold to form the final product static plate.

Embodiment 2

[0034] The aluminum alloy material composed of the following mass percentage components is smelted at 753°C, and 0.011% of the aluminum alloy mass detonator and 1.1% of the reinforcing agent are added during the smelting, and the iron rake is repeatedly stirred for 26 minutes to completely melt it to obtain molten aluminum; The composition and mass percentage of alloy materials: Si: 6.2%, Fe: 0.105%, Mg: 0.52%, Zr: 0.011%, Ti: 0.024%, B: 0.031%, La: 0.023%, the balance is aluminum Avoided impurities; refining the molten aluminum with a refining temperature of 784°C. After refining, it is cooled to 692°C, while the mold is preheated to 158°C, and the cooling liquid is poured into the mold to form the final product static plate.

Embodiment 3

[0036] The aluminum alloy material composed of the following mass percentage components is smelted at 756°C, and 0.012% of the aluminum alloy mass detonator and 1.2% of the reinforcing agent are added while smelting, and the iron rake is repeatedly stirred for 27 minutes to completely melt it to obtain molten aluminum; The composition and mass percentage of alloy materials: Si: 6.4%, Fe: 0.11%, Mg: 0.54%, Zr: 0.012%, Ti: 0.038%, B: 0.032%, La: 0.026%, the balance is aluminum Avoid impurities; then refining the molten aluminum with a refining temperature of 788°C. After refining, it is cooled to 694°C, while the mold is preheated to 166°C, and the cooling liquid is poured into the mold to form the final product static plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com