A test system for suppressing underground gas explosions in coal mines with a cavity structure

A technology of structural restraint and test system, applied in mining equipment, dust prevention, earth square drilling, etc., can solve problems such as increased ground stress, increased gas pressure, and increased low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

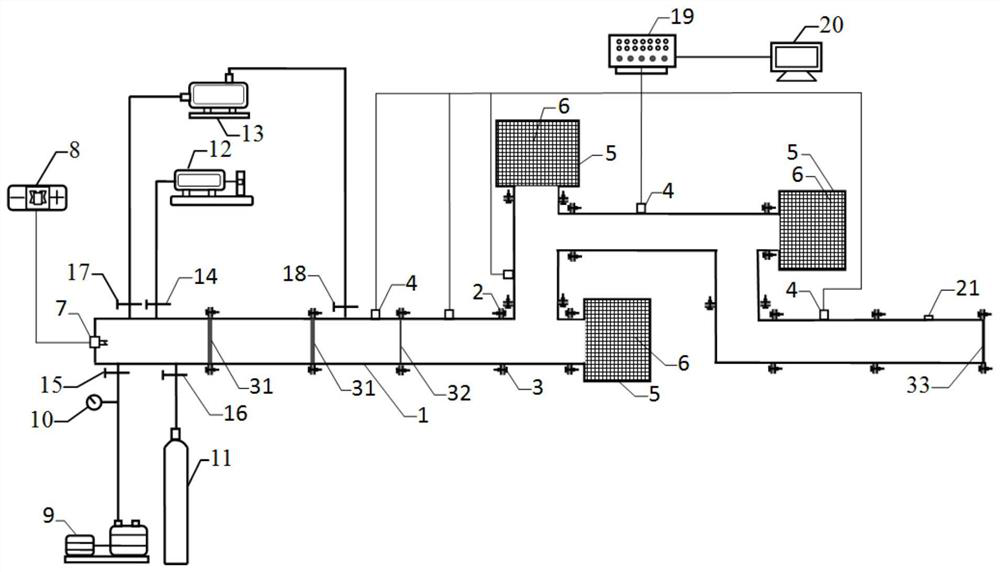

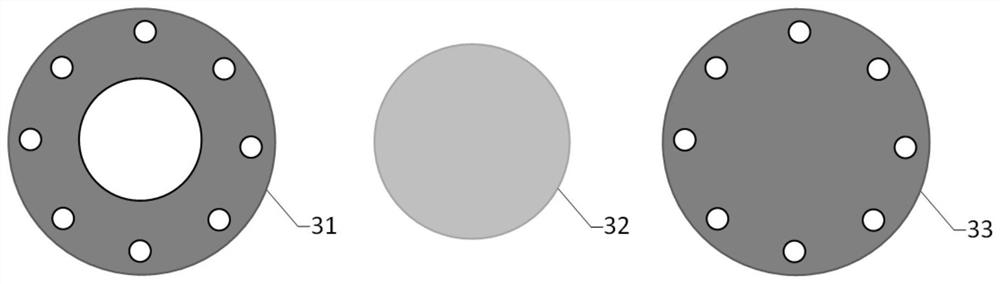

[0017] like figure 1 As shown, as an example, a test system for suppressing underground gas explosion in a coal mine with a cavity structure includes a pipe 1, a flange 2, bolts and nuts 3, a pressure sensor 4, a cavity structure 5, energy-consuming materials 6, electrodes 7. AC power supply 8, vacuum pump 9, digital vacuum gauge 10, high-purity methane cylinder 11, air compressor 12, circulation pump 13, pressure valve 14, suction valve 15, intake valve 16, first circulation valve 17, Second circulation valve 18, dynamic data collector 19, upper computer 20, exhaust port 21, accelerator sheet 31, diaphragm 32 and steel sheet 33; The schematic diagram of accelerator sheet 31, diaphragm 32 and steel sheet 33 is as figure 2 As shown, wherein, the diaphragm 32 is made of polyethylene material, its thickness is 0.5-2 mm, and its diameter is 1-3 cm larger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com