Large-length-diameter-ratio optical fiber nanoprobe and preparation method and application thereof

A large aspect ratio, nano-probe technology, applied in the direction of using optical devices, material analysis by optical means, instruments, etc., can solve problems such as more difficult and difficult measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

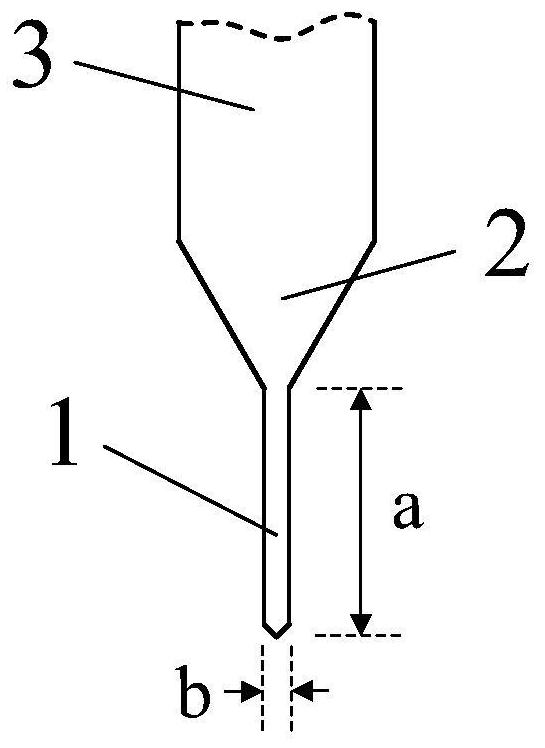

[0040] The present invention also provides a method for preparing an optical fiber nanoprobe with a large aspect ratio, comprising the following process:

[0041] Inserting one end of the optical fiber vertically into the corrosion solution to corrode the optical fiber, corroding the end of the optical fiber to obtain an optical fiber slender needle with a preset diameter, and processing the optical fiber slender needle so that the optical fiber slender needle reaches a preset length, The length-to-diameter ratio of the fiber optic elongated needle with the preset length is not less than 20:1.

[0042] As a preferred embodiment of the present invention, the process of processing the elongated fiber optic needle so that the elongated fiber optic needle reaches a preset length includes:

[0043] After the end of the optical fiber is corroded to obtain an optical fiber slender needle with a preset diameter, the optical fiber is pulled upwards, so that the length of the optical fi...

Embodiment

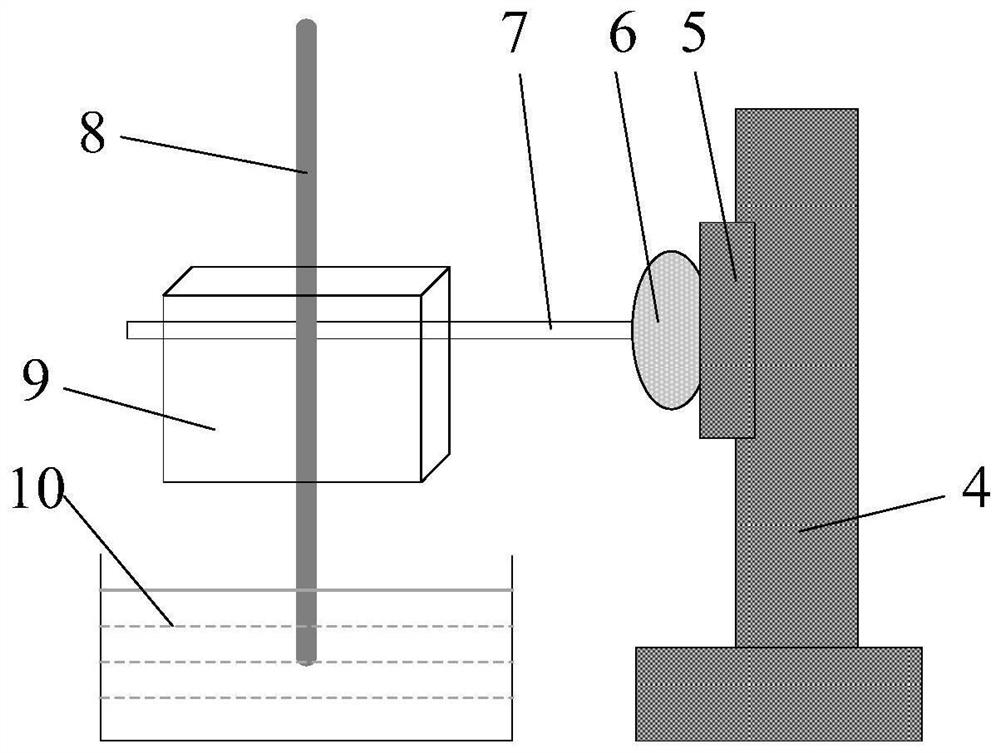

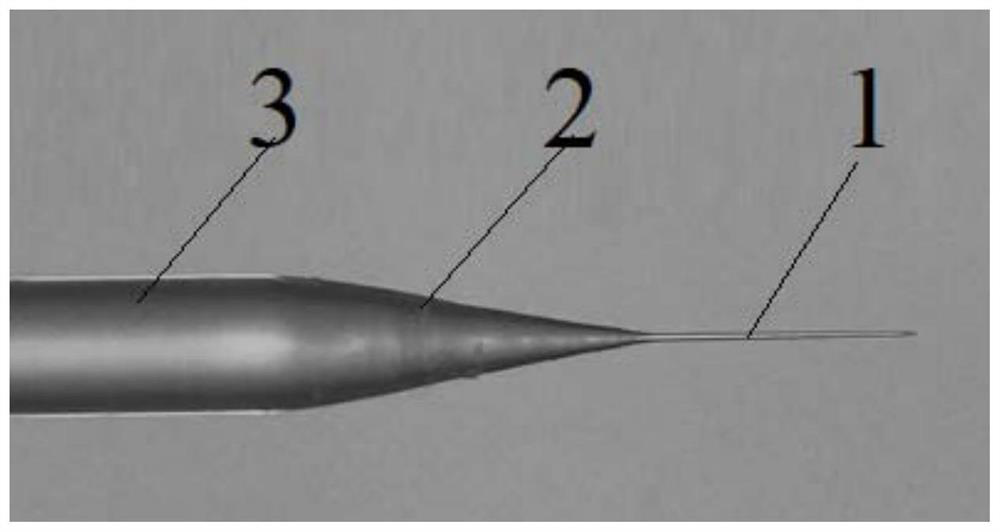

[0050] In this embodiment, the preparation method of optical fiber nanoprobe with large aspect ratio refers to figure 2 , first configure the HF solution with a solute mass percentage of 40% concentration, put one end of the single-mode optical fiber vertically into the HF solution 10 through the optical fiber holder 9, after a preset time, the optical fiber is corroded to a preset diameter, Then pull the optical fiber out of the solution to a preset height and fix it. This height is the final length of the fiber optic slender needle, and then corrode the excess length in the etching solution to form a tapered transition between the optical fiber and the slender needle tip. area, which serves as a light-gathering structure. During the preparation process, parameters should be controlled to ensure that the fiber optic elongated needle has a cylindrical structure and the tip of the needle is tapered. The specific method is that when the optical fiber holder clamps the optical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com