Wide-frequency-band wind-induced vibration piezoelectric power generation device

A wind-induced vibration and piezoelectric power generation technology, which is applied to wind power generation, wind turbines that are consistent with the wind direction, wind turbines, etc., can solve the problem of high requirements for the manufacture and installation of planetary gear trains, ineffective power generation of power generation devices, and large starting torque, etc. problems, to achieve the effect of improving wind energy collection efficiency, increasing power generation, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

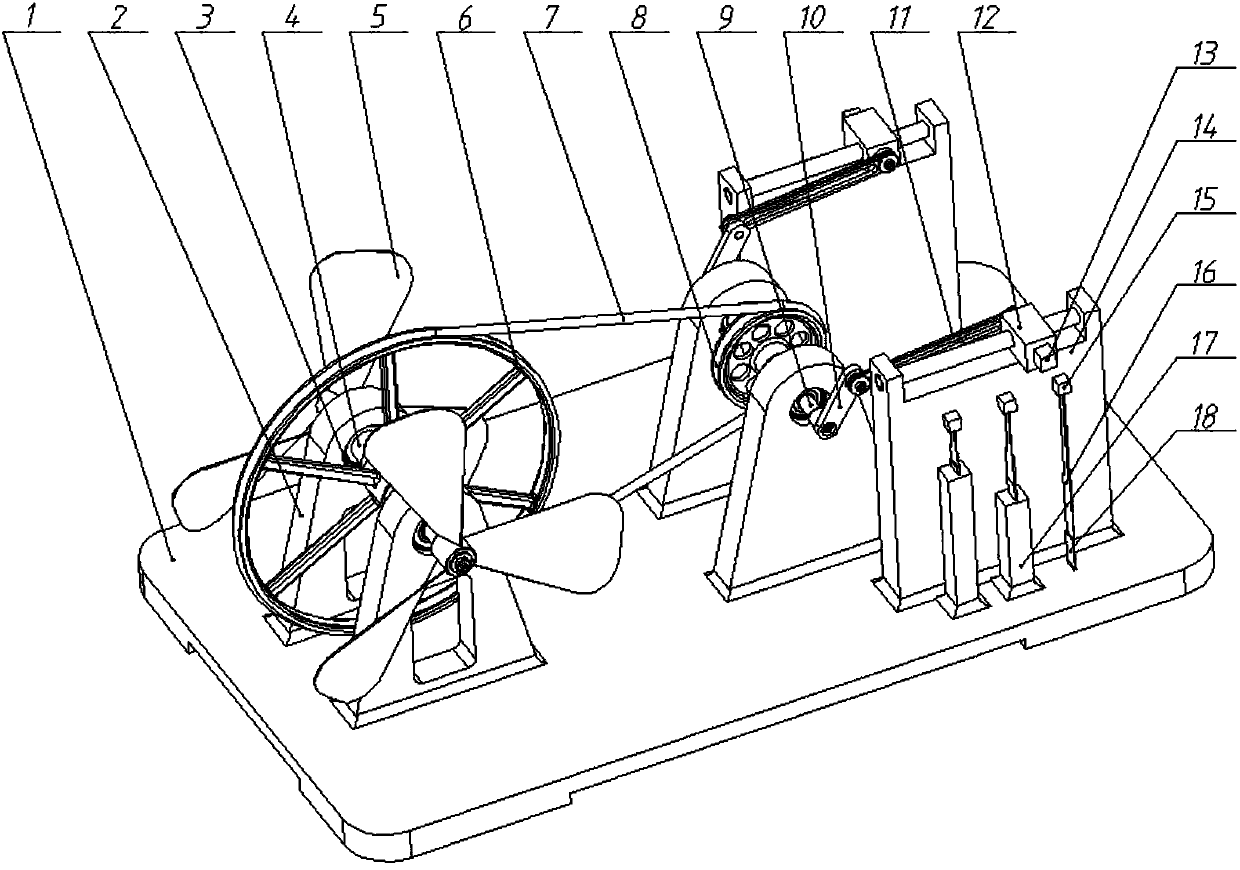

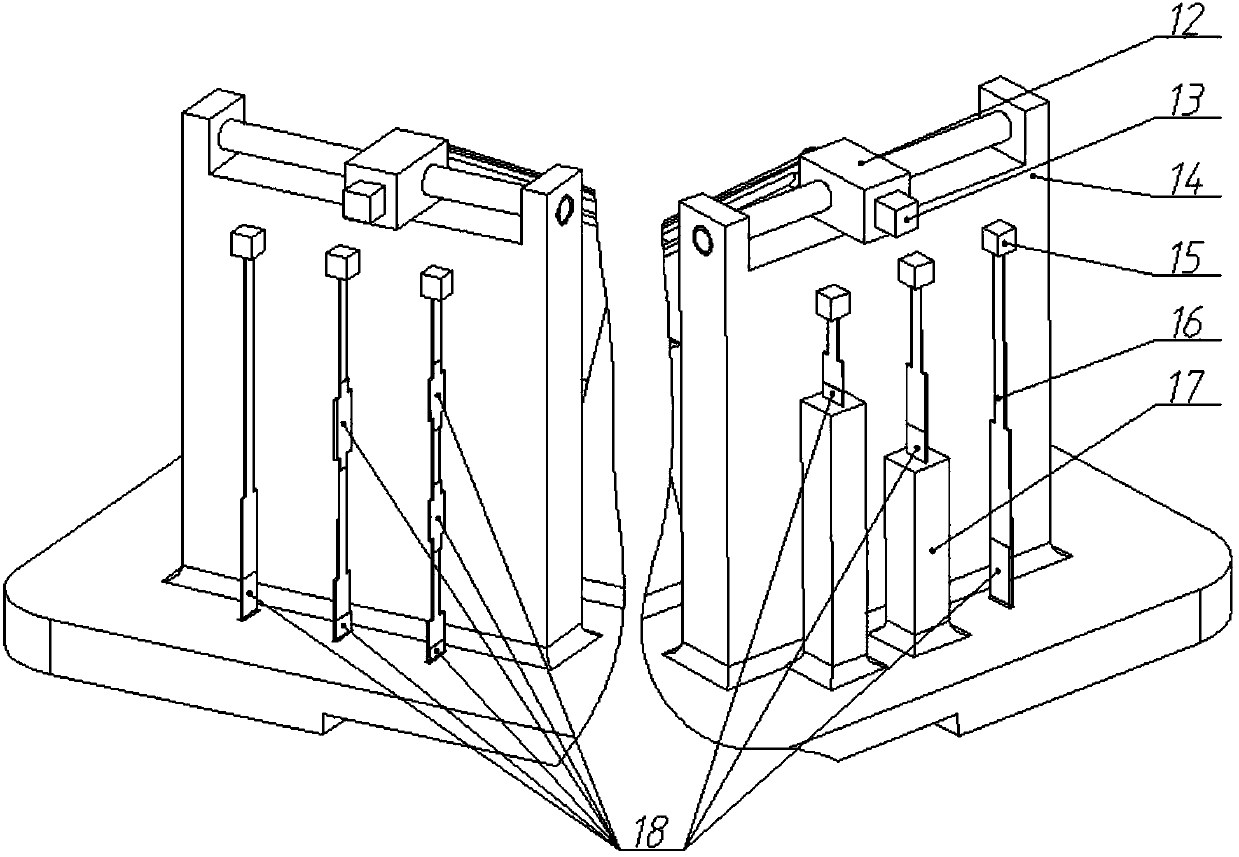

[0039] Embodiment: a broadband wind-induced vibration piezoelectric power generation device, constituted as figure 1 As shown, it includes a base 1 on which a bracket 2, a slider guide rail 14 and a cantilever beam support 17 are fixed, an input shaft 4 and an output shaft 9 are arranged on the bracket 2, and a rolling bearing is installed between the input shaft 4 and the bracket 2 3. A wind wheel 5 is installed on the shaft heads at both ends of the input shaft 4, a driving pulley 6 is installed on the middle part of the shaft head, a driven pulley 8 is installed on the middle part of the output shaft 9, and the driving pulley 6 and Drive belt 7 is housed on the driven pulley 8, and an end of crank 10 is respectively installed on the axle head of output rotating shaft 9 two ends, and the other end of crank connects an end of connecting rod 11, and the other end of connecting rod connects slide block 12, and slide block 12 can The slider guide rail 14 reciprocates, the slider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com