Centrifugal blower

A centrifugal fan and fan technology, which is used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of not meeting the needs of clean and pollution-free, large fan equipment, energy loss and noise, etc., to meet the needs of clean and pollution-free. , The effect of compact structure and low energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

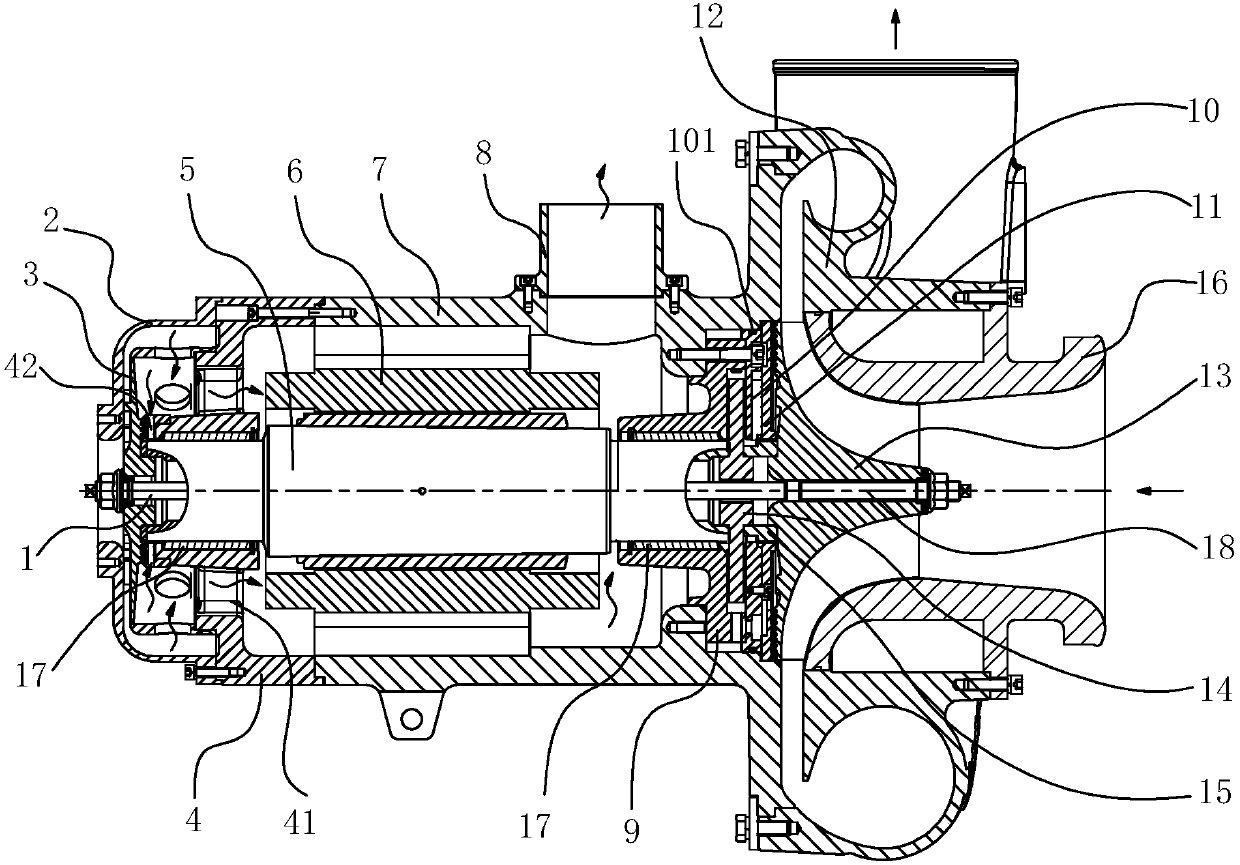

[0020] The present invention will be described in further non-limiting detail below in conjunction with the accompanying drawings and examples.

[0021] For the convenience of description, in this paper, the end face of the component away from the center of the main shaft is defined as the outer end face, and the end face close to the center of the main shaft is defined as the inner end face; the terms "first", "second", etc. are only used for description purposes and cannot be understood as indicate or imply relative importance; figure 1 In , the straight arrow indicates the flow direction of the delivered gas, and the curved arrow indicates the air flow direction.

[0022] Such as figure 1 As shown, the centrifugal fan in the embodiment of the present invention includes: a motor 6, a fan 3 driven by the motor 6 and an impeller 13, the impeller 13 is arranged in the compressor housing 12, and the fan 3 is provided with a fan cover 2, and the motor 6 is preferably a permanent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com