Method for realizing synchronous characterization of mechanical properties of graphene based on fold formation principle

A technology of graphene and graphene layers, which is applied in the field of graphene, can solve the problems of evaluation and inability to adapt to the elastic modulus of graphene, etc., and achieve the effects of reducing experimental errors, cost reduction, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

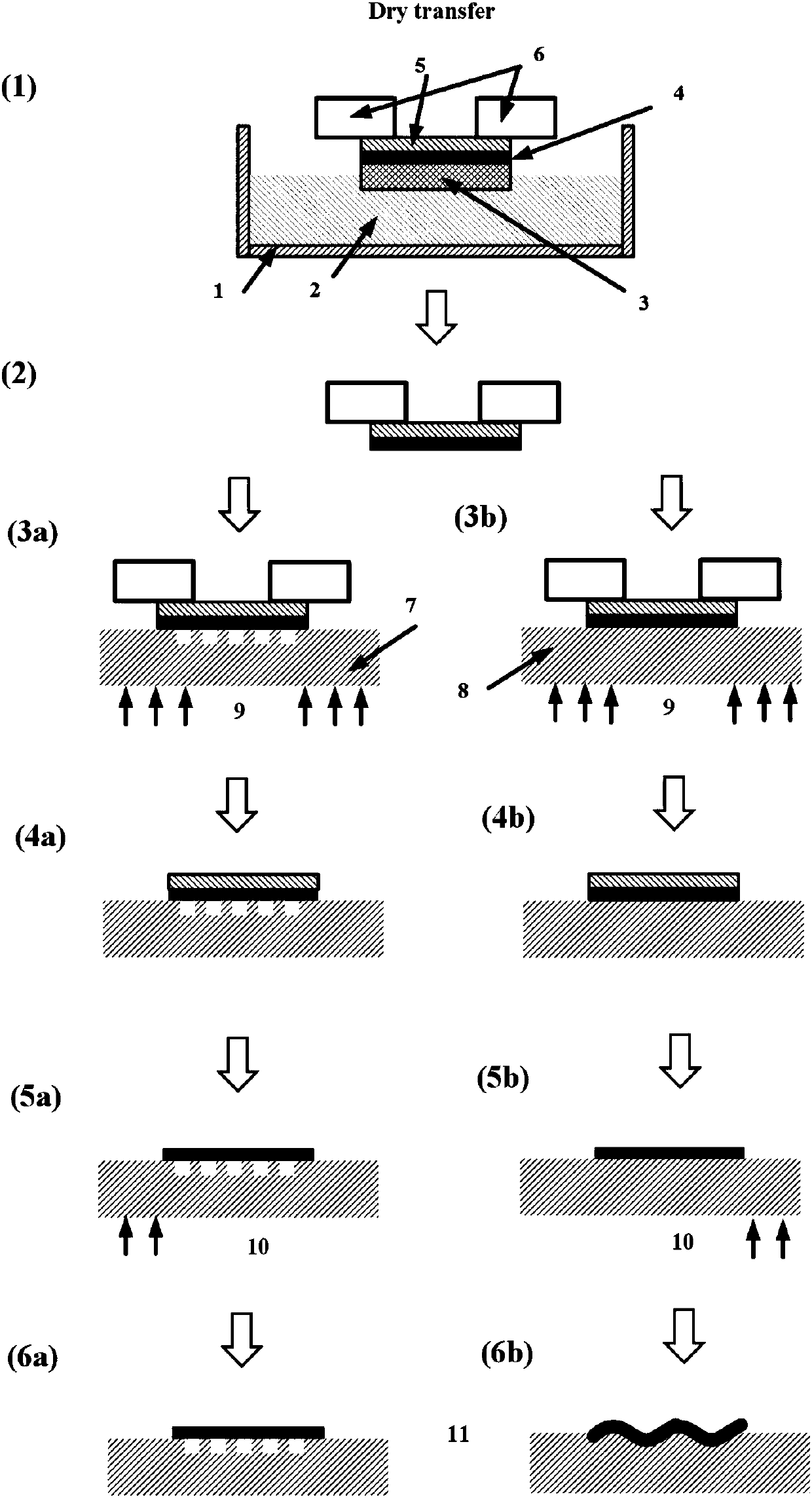

[0025] Such as figure 1 As shown, this embodiment includes the following steps:

[0026] ① First, high-quality single-layer graphene 4 is deposited on the copper foil 3 by CVD method, and then the PMMA layer 5 as a commonly used carrier material is spin-coated on the graphene layer 4 .

[0027] ②For a 2μm deep well, a PMMA solution with a concentration of 120mg / mL was spin-coated onto graphene / copper foil at a spin-coating speed of 4000rpm for 30 seconds, and dried in air; for a deep well of 300nm, a PMMA solution with a concentration of 120mg / mL, Spin coating speed 1000rpm, 30 seconds.

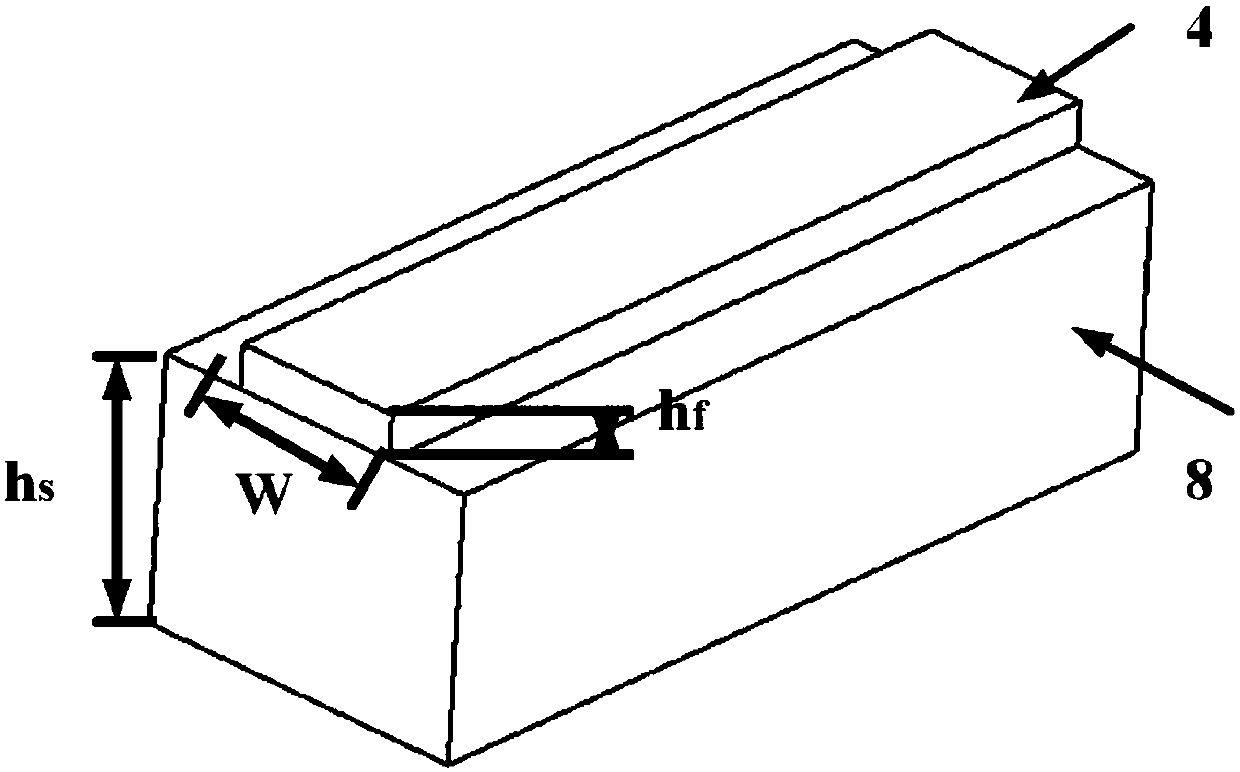

[0028] ③ Use PDMS block 6 as an elastic frame support to naturally adsorb on the combined film of PMMA layer 5 / graphene 4, so that the film can be removed from the etchant and placed on the target substrate 7 or test substrate 8 .

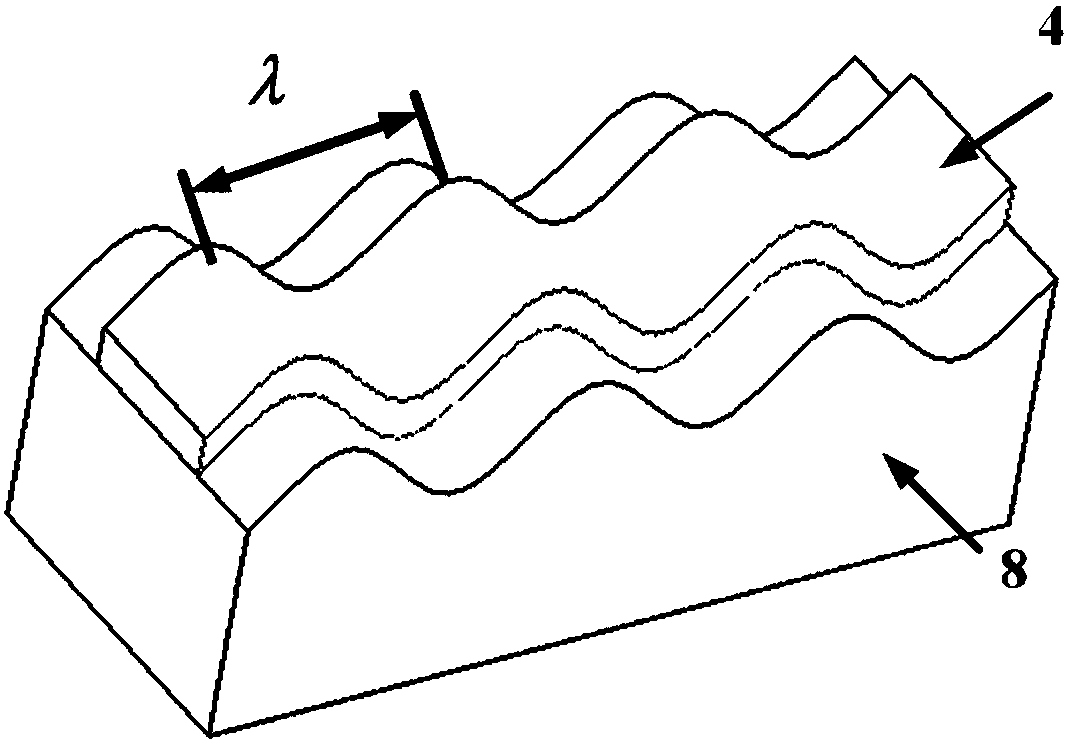

[0029] ④Substrate heating exceeds T g (125° C.), heat treatment at 150° C. for 12 hours enables the undulating and rough PMMA layer 5 / graphene 4 combination fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com