Dual-rotor axial disk-type permanent magnet motor

A technology of permanent magnet motor and axial disk, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of large motor volume, complex drive circuit, high weight, etc., and achieve reduction of motor quality, simplification of motor structure, and optimization of array structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

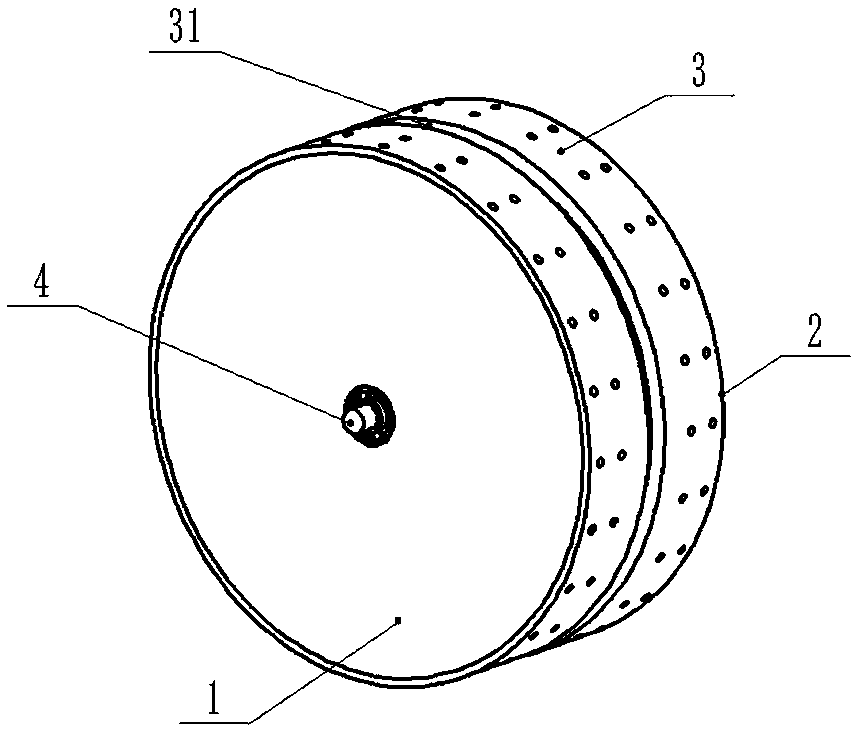

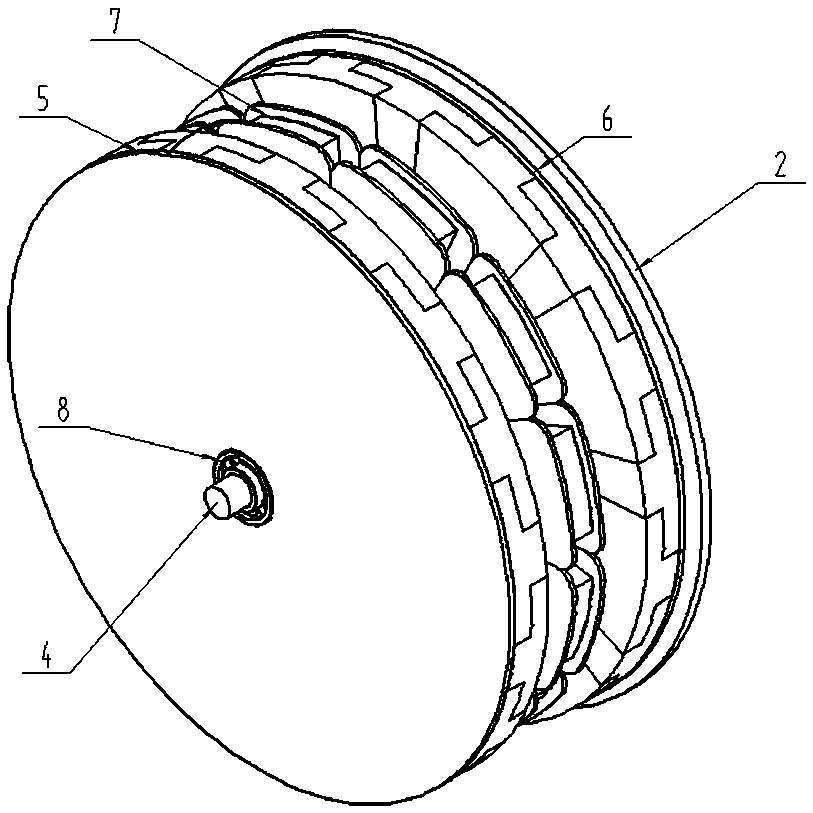

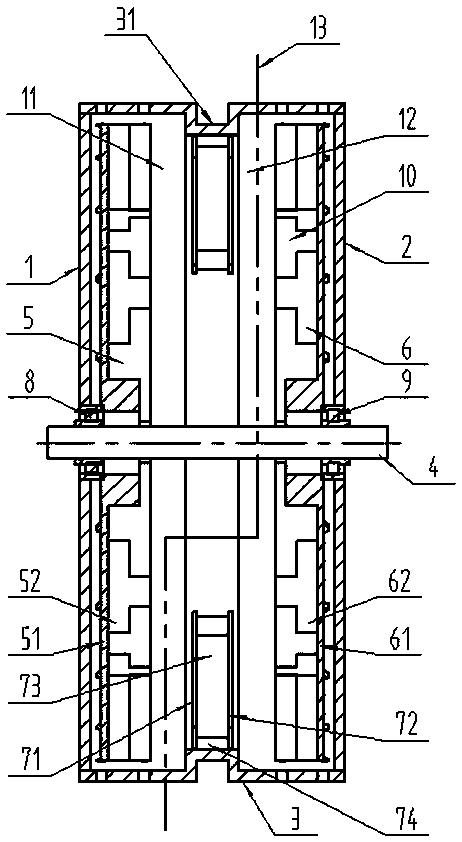

[0034] see figure 1 , figure 2 and image 3 , a dual-rotor axial disc permanent magnet motor includes an annular casing 3 , a stator 7 , a first rotor 5 , a second rotor 6 and an output shaft 4 . Cooling holes are evenly distributed on the circumference of the casing 3, the stator 7 is installed on the inner cylindrical surface of the casing 3; the output shaft 4 is installed on the axial center of the casing 3, and the first rotor 5 and the second rotor 6 are mirror-symmetrical It is installed on the rotating shafts on both sides of the stator 7 and rotates with the output shaft 4 .

[0035] see Figure 4 , The stator 7 is a yoke-free segmented ring structure, consisting of twelve stator units. Each stator unit is composed of a first pole piece 71 , a second pole piece 72 and a stator core 73 . The stator core 73 is a fan-shaped flat blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com