Large-load cargo elevator hanging system with traction ratio being 6:1

A technology of suspension system and traction ratio, which is applied in elevators in buildings, lifting equipment in mines, transportation and packaging, etc., can solve the problems of small spindle load, difficult to increase product speed, and low operating efficiency, and achieve Stable force balance, reliable elevator operation, and reduced load requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

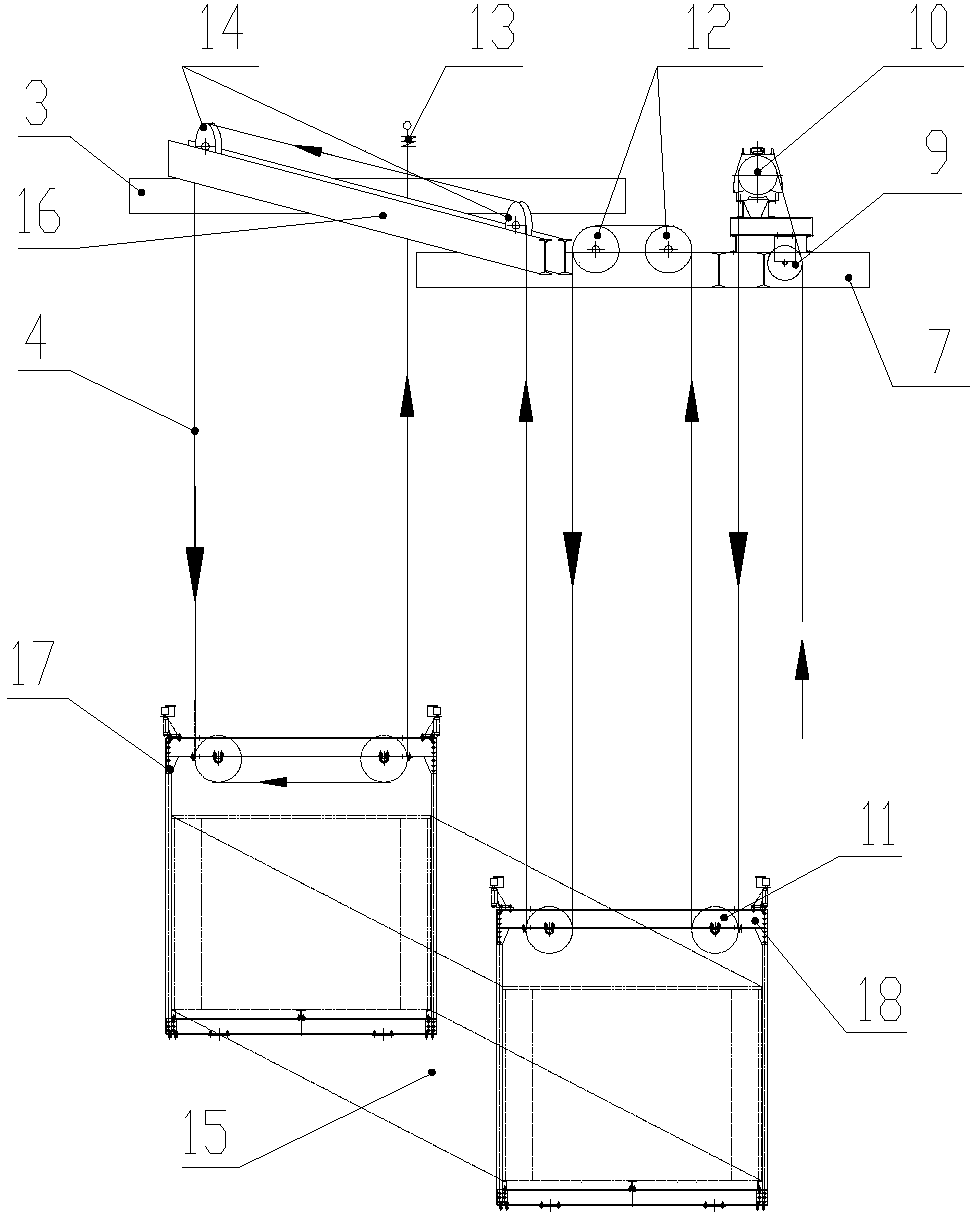

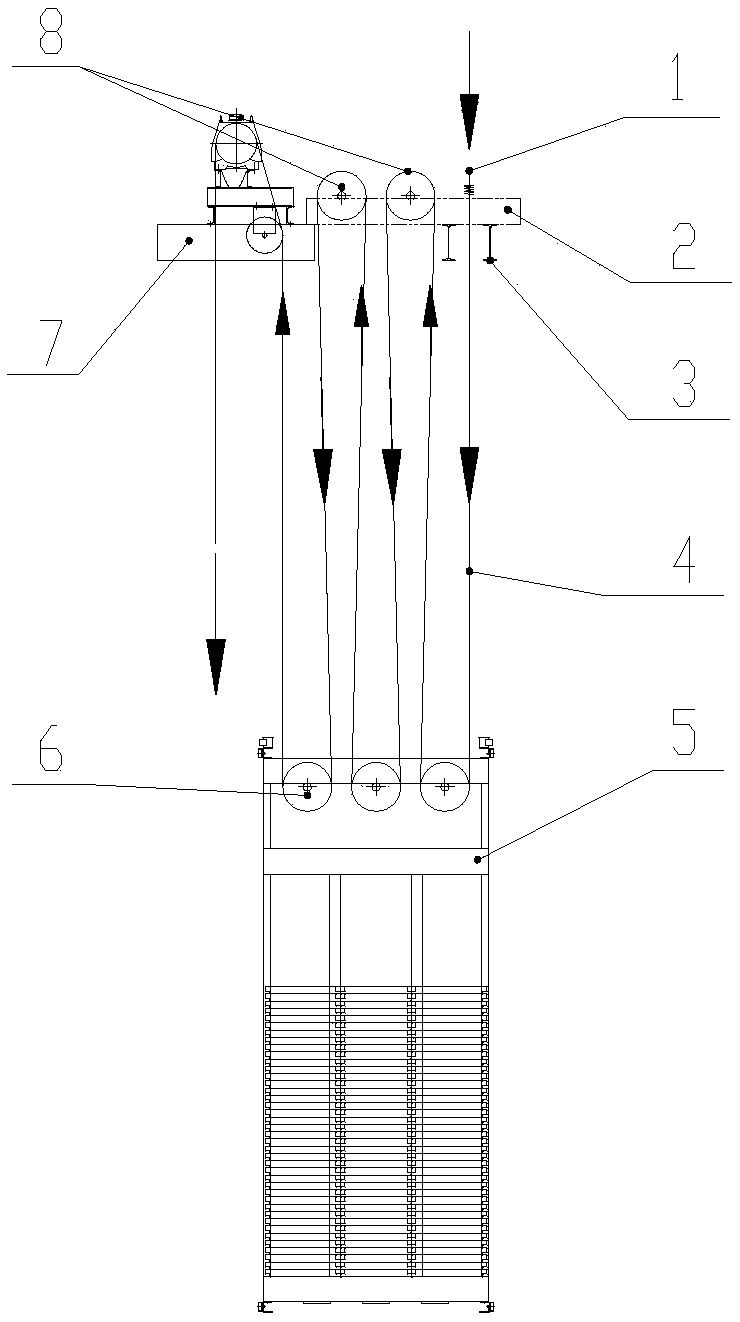

[0024] This embodiment is a large-load freight elevator suspension system with a traction ratio of 6:1, including a car 15, a counterweight assembly 5, and a load-bearing steel beam for a machine room at the top.

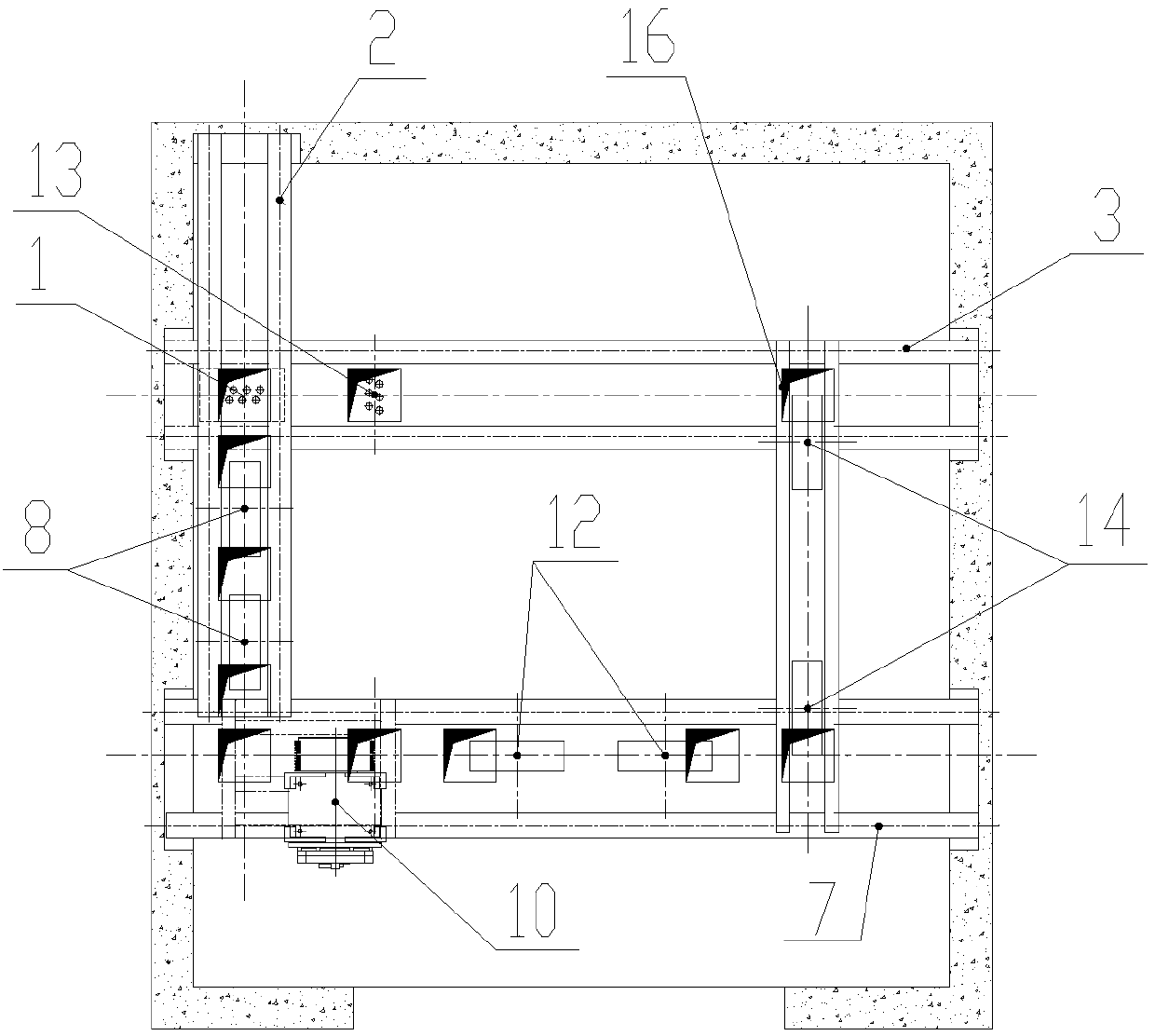

[0025] Among them, the load-bearing steel beam of the machine room is a "well"-shaped structure, such as figure 1 As shown, it includes two parallel arranged rope head steel beams 3 and main engine steel beams 7, and another two parallel arranged counterweight steel beams 2 and guide steel beams 16; the guide steel beams 16 are located between the rope head steel beams 3 and Above one end of the main frame steel beam 7. The main engine steel girder 7 corresponds to the front car frame 18 on the car 15, and the rear car frame 17 of the car 15 is corresponding below the rope end steel girder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com