Rapid Preparation of Porous Graphene by Local Combustion

A technology of porous graphene and combustion method, which is applied in the direction of graphene and nano-carbon, which can solve the problems that restrict the large-scale preparation and production of porous graphene, complex equipment requirements, and long synthesis time, so as to save synthesis time and simplify synthesis The effect of simple steps and reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

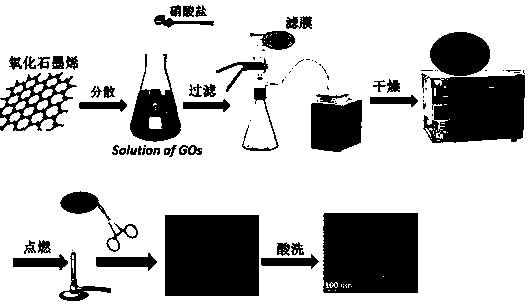

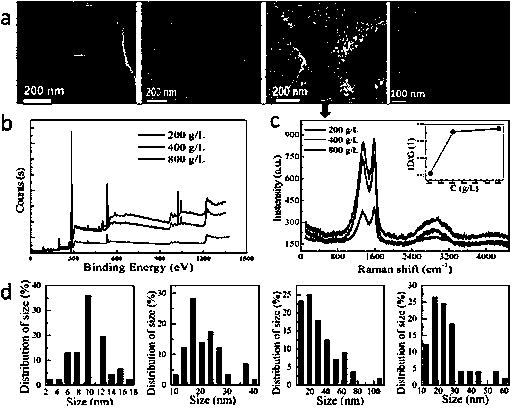

[0016] The preparation of embodiment 1 porous graphene

[0017] Steps:

[0018] 1. First prepare 2 mL of 1 g / L graphene oxide suspension, and ultrasonicate at room temperature for 10 min.

[0019] 2. Weigh 50 mg of zinc nitrate, dissolve it in the above suspension, and sonicate for 2 min.

[0020] 3. Suction filter the above solution with quantitative filter paper.

[0021] 4. Dry the filter paper and residue at 35°C.

[0022] 5. Ignite the filter paper with the residue and sinter until white zinc oxide covered porous graphene appears.

[0023] 6. Wash 4 times with 0.01 mol / L hydrochloric acid and wash 3 times with water to obtain porous graphene.

Embodiment 2

[0024] The preparation of embodiment 2 porous graphene

[0025] Steps:

[0026] 1. First prepare 2 mL of 1 g / L graphene oxide suspension, and ultrasonicate at room temperature for 10 min.

[0027] 2. Weigh 100 mg of zinc nitrate, dissolve it in the above suspension, and sonicate for 2 min.

[0028] 3. Suction filter the above solution with quantitative filter paper.

[0029] 4. Dry the filter paper and residue at 35°C.

[0030] 5. Ignite the filter paper with the residue and sinter until white zinc oxide covered porous graphene appears.

[0031] 6. Wash 4 times with 0.01 mol / L hydrochloric acid and wash 3 times with water to obtain porous graphene.

Embodiment 3

[0032] The preparation of embodiment 3 porous graphene

[0033] Steps:

[0034] 1. First prepare 2 mL of 1 g / L graphene oxide suspension, and ultrasonicate at room temperature for 10 min.

[0035] 2. Weigh 200 mg of zinc nitrate, dissolve it in the above suspension, and sonicate for 4 min.

[0036] 3. Suction filter the above solution with quantitative filter paper.

[0037] 4. Dry the filter paper and residue at 35°C.

[0038] 5. Ignite the filter paper with the residue and sinter until white zinc oxide covered porous graphene appears.

[0039] 6. Wash 4 times with 0.01 mol / L hydrochloric acid and wash 3 times with water to obtain porous graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com