Formula and method for preparing sprayed concrete through coal-to-oil residues

A shotcrete and coal-to-oil technology, applied in the field of cement concrete materials, can solve problems such as affecting the healthy development of enterprises, and achieve the effects of protecting the natural ecological environment, reducing dust and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

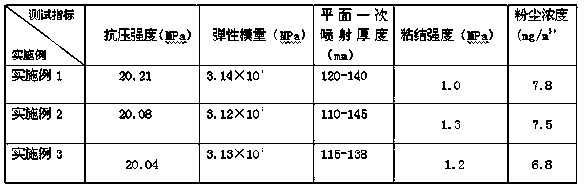

Examples

Embodiment 1

[0025] Sieving the coal-to-oil residue through a filter sieve to obtain coal-to-oil residue with a particle size of 0.1-10 mm for use;

[0026] Take 60 parts of the above-mentioned coal-to-oil residue, 25 parts of Jin brand ordinary Portland cement, 8 parts of water, and 3 parts of composite admixture. The composite admixture is composed of silica fume, S95 mineral powder, and redispersible latex powder. The weight ratio of the latter is 1:1:0.2;

[0027] Mix the raw materials in the above parts by weight evenly to obtain the shotcrete material with grade C40 of the present invention, which can be used in the conventional shotcrete process.

Embodiment 2

[0029] Sieving the coal-to-oil residue through a filter sieve to obtain coal-to-oil residue with a particle size of 0.1-10 mm for use;

[0030] Take 55 parts of the above-mentioned coal-to-oil residue, 15 parts of Jin brand ordinary Portland cement, 5 parts of water, and 1 part of composite admixture. The composite admixture is composed of silica fume, S95 mineral powder, and redispersible latex powder. The weight ratio of the latter is 1:1:0.2;

[0031] Mix the raw materials in the above parts by weight evenly to obtain the shotcrete material with grade C40 of the present invention, which can be used in the conventional shotcrete process.

Embodiment 3

[0033] Sieving the coal-to-oil residue through a filter sieve to obtain coal-to-oil residue with a particle size of 0.1-10 mm for use;

[0034] Take 80 parts of the above-mentioned coal-to-oil residue, 35 parts of Jin brand ordinary Portland cement, 10 parts of water, and 4 parts of composite admixture. The composite admixture is composed of silica fume, S95 mineral powder, and redispersible latex powder. The weight ratio of the latter is 1:1:0.2;

[0035] Mix the raw materials in the above parts by weight uniformly to obtain the shotcrete material with a strength grade of C40 of the present invention, which can be used in conventional shotcrete technology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com