Resin composition for optical semiconductor, manufacturing method thereof, and optical semiconductor device

A resin composition and optical semiconductor technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as lack of productivity, large transmittance changes, and increased brightness changes, and achieve excellent sealing workability and molding operations Excellent performance and good productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

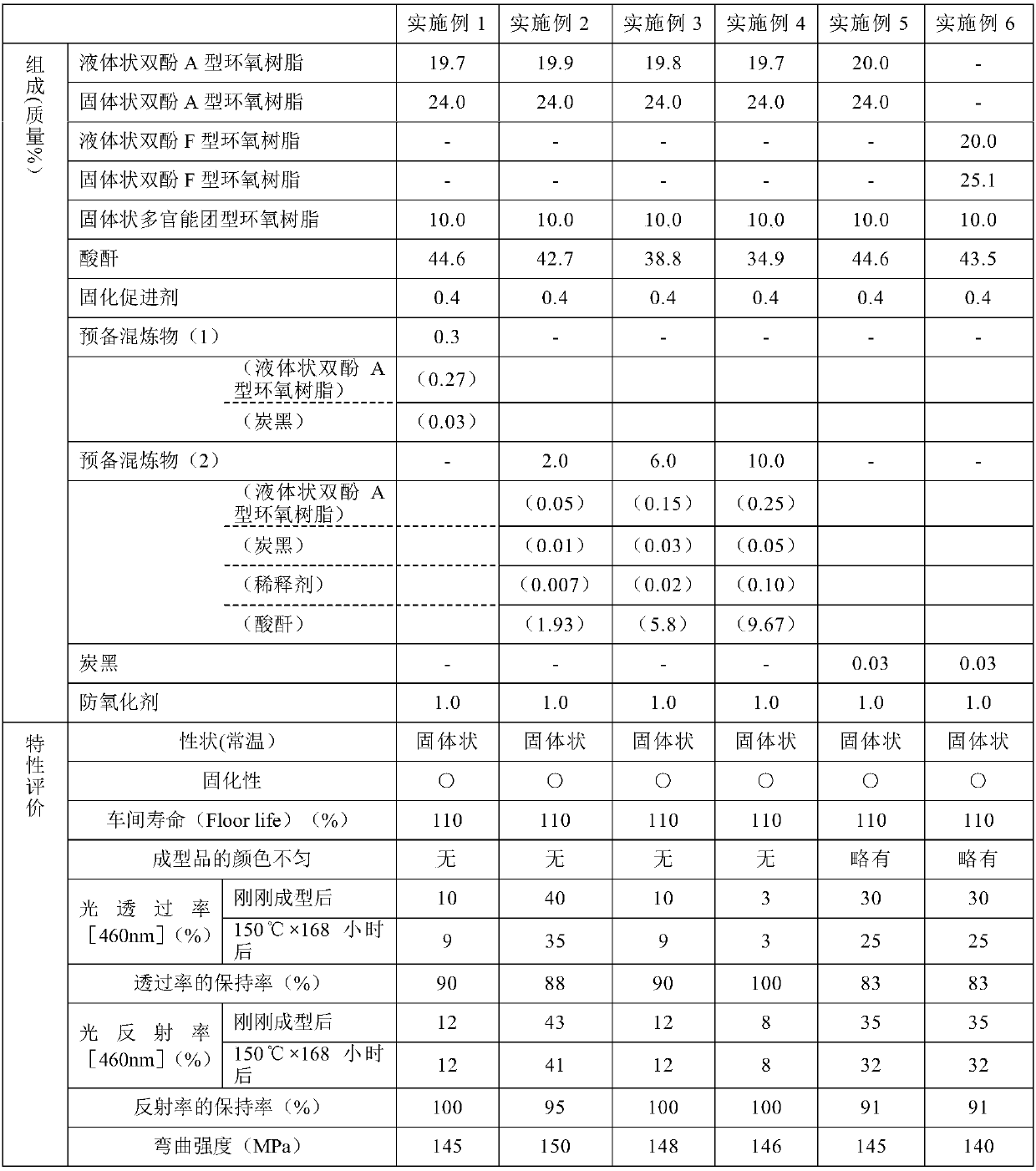

Embodiment 1

[0061] In order to obtain the compounding amount of the composition shown in Table 1, first, the above-mentioned pre-kneaded product (1), liquid bisphenol A epoxy resin ("YD-8125") at room temperature, bisphenol A type epoxy resin ("YD-8125") solid at room temperature, Phenol A type epoxy resin (produced by Mitsubishi Chemical Co., Ltd., trade name "Epikote 1002" ("Epikote 1002")), a trifunctional epoxy resin with a triazine skeleton in a solid state at room temperature (Nissan Chemical Industry Co., Ltd. ), product name "TEPIC-S"), liquid acid anhydride at room temperature (manufactured by Shin Nippon Chemical Co., Ltd., product name "RIKACID MH-700" ("RIKACID MH-700")), and di Butylated hydroxytoluene (BHT) is mixed at a temperature of 70°C by a universal mixer, and secondly, in the mixture, dimethyl tributylphosphonium phosphate (manufactured by Nippon Chemical Industry Co., Ltd.) is added as a curing accelerator , trade name "ヒシコーリン PX-4MP" ("HISHICOLINPX-4MP")), further k...

Embodiment 2~4

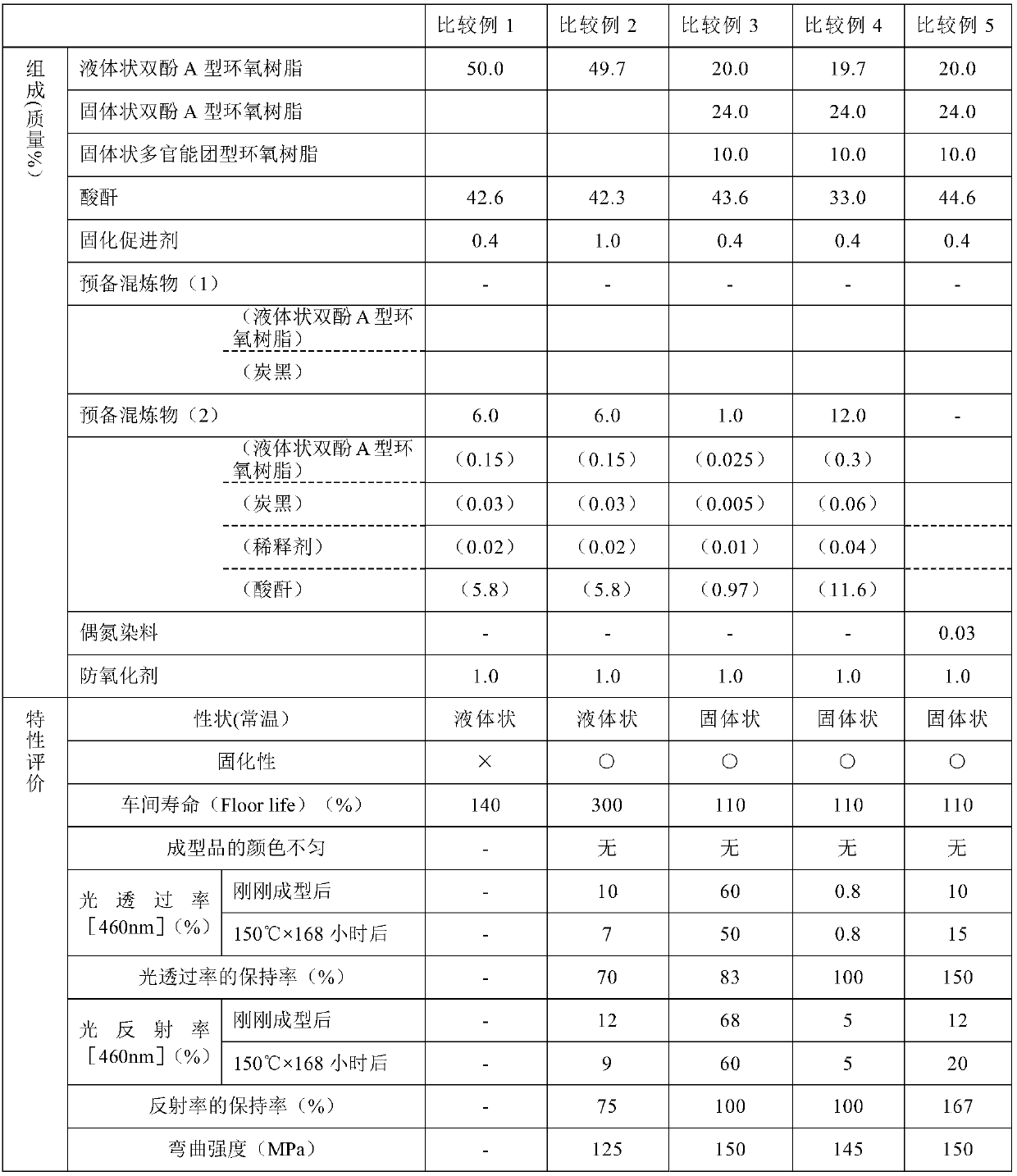

[0062] (Examples 2-4, Comparative Examples 1-4)

[0063] Except that the pre-kneaded product (2) was used instead of the pre-kneaded product (1), and the compounding amount was set so that the compounding amount of each component became the composition shown in Tables 1 and 2, it was the same as in Example 1. operation to obtain a resin composition for optical semiconductors.

Embodiment 5

[0065] Except having mixed carbon black and another component as it was without using the pre-kneaded product, it carried out similarly to Example 1, and obtained the resin composition for optical semiconductors of the composition similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com